What is Thermal hydrolysis?

Thermal hydrolysis is a method used in anaerobic digestion wastewater treatment plants. Thermal hydrolysis involves exposing sewage sludge or other moist organic waste to extreme heat and pressure. The procedure is comparable to steam-cooking dishes.

The processes involved

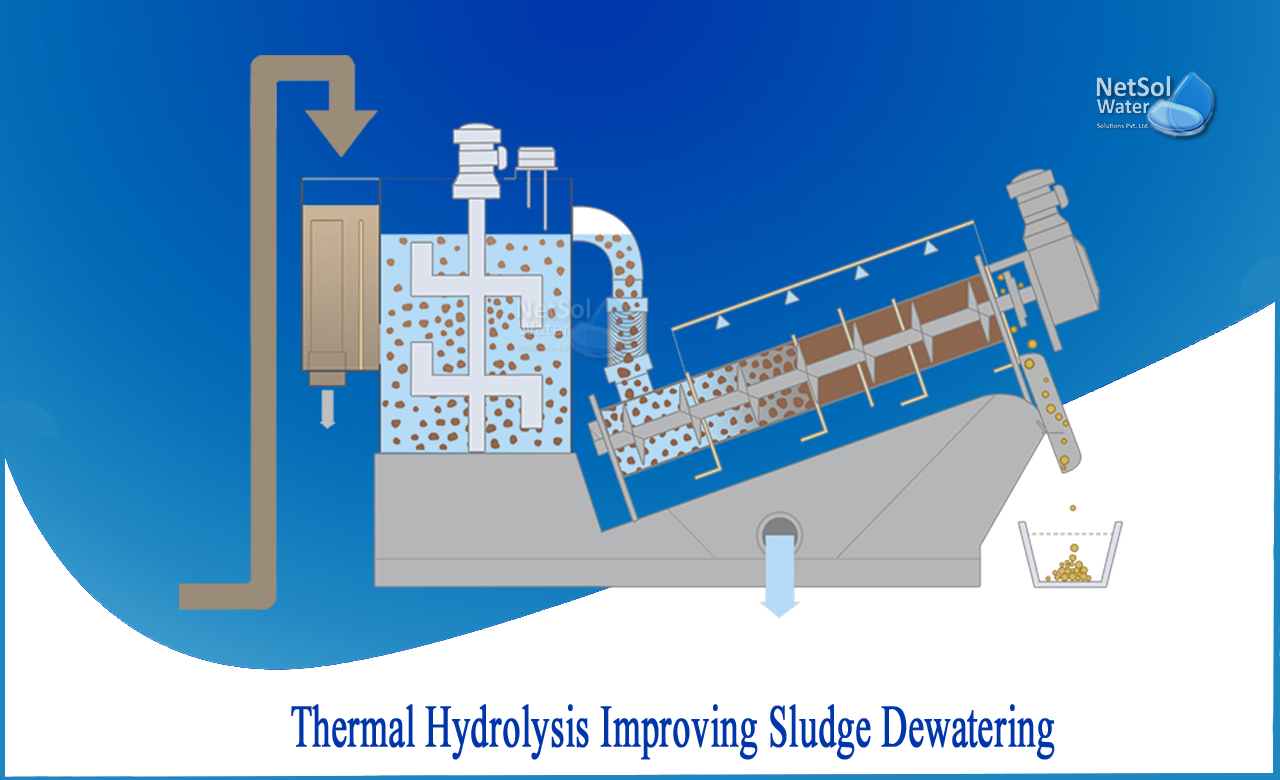

The first process - Raw sewage sludge is collected and dewatered to 16-18% dry solids at the wastewater treatment plant's primary and secondary treatment units. The pulper is constantly fed to this thicker sludge. Using steam recovered from the flash tank, the pulper homogenises and pre-heats the sludge to a temperature near 100°C.

The second process - Warm sludge is continuously delivered to the reactors from the pulper, in a sequential procedure that ensures sealed batches of sludge in each reactor. Sludge flows to the next available reactor after one is full. A thermal hydrolysis typically has 2 to 5 reactors, depending on sludge amount, reactor size, and hydraulic retention duration.

The last process - Now sterilised sludge is transferred from the reactor to the flash tank, which runs at atmospheric pressure. The sewage sludge's organic matter suffers significant cell damage as a result of the abrupt pressure reduction. The pressure release generates steam, which is returned to the pulper to warm the incoming sludge. After leaving the flash tank, the sludge is cooled through heat exchangers to the temperature required for anaerobic digestion. After that, it's fed to anaerobic digesters.

What is Sludge?

Sludge is a semi-solid slurry created by a range of industrial and municipal activities.The goal of sludge dewatering is to concentrate wastes into high solids filter cakes that can be easily and inexpensively disposed of. Sludge disposal is supervised by tight guidelines. Most businesses, communities, and institutions have sustainability goals that are aligned with statutory obligations as well as their own organisational and environmental needs.

Benefits of sludge dewatering

Dewatering equipment is a cost-effective way to manage sludge accumulation by lowering transportation and storage costs. Also, cake dryness is uniform when sludge dewatering filter presses are used. The dry, high-solids cakes not only save transportation expenses, but they also reduce the chance of spilling or leaking into the roads. This is a significant problem, especially when trucking through residential neighbourhoods.

The most important of this process is recycling of wastewater. Industries and communities can reclaim the treated water from sludge dewatering after it is free of risks and impurities. Despite the fact that the water is usually not potable, it has a wide range of uses.

Steam-powered plants are an excellent illustration of how reclaimed water may benefit a business or community.

How thermal hydrolysis improve sludge dewaterability?

Since of its effect on this specific sludge quality, among others, the thermal hydrolysis procedure (THP) enhances digestate dewaterability. THP disintegrates sludge particles, altering sludge viscosity and water distribution, by treating it at high temperature and pressure before discharging it in a flash tank. Water distribution in sludge refers to the varied states of water that affect how difficult it is to separate from solid particles. It includes –

· Free water,

· Interstitial water,

· Surface water,

· Intracellular water.

"Bound water" is combination ofinterstitial, surface, and intracellular water that cannot be removed by mechanical dewatering. These are the ones that are commonly found in waste activated sludge. Thermal hydrolysis alters the characteristics of the sludge, releasing interstitial water into the bulk liquid, resulting in free water that may be mechanically separated.

Conclusion

Dewaterability of digestate can be defined in two ways:

How quickly the product can be dewatered (rate of separation) and how much dryness can be attained in the final product (extent of separation).

THP-treated sludge clearly outperforms normally digested sludge in terms of dewaterability. Thermal hydrolysis considerably enhances the dryness of the final biosolids cake with dewatering because it disintegrates organics and permits interstitial water to become free water within the digestate. As a result, the volume of biosolids produced is lowered dramatically, resulting in cost savings for wastewater treatment plants and food waste processing companies that use the technology.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.