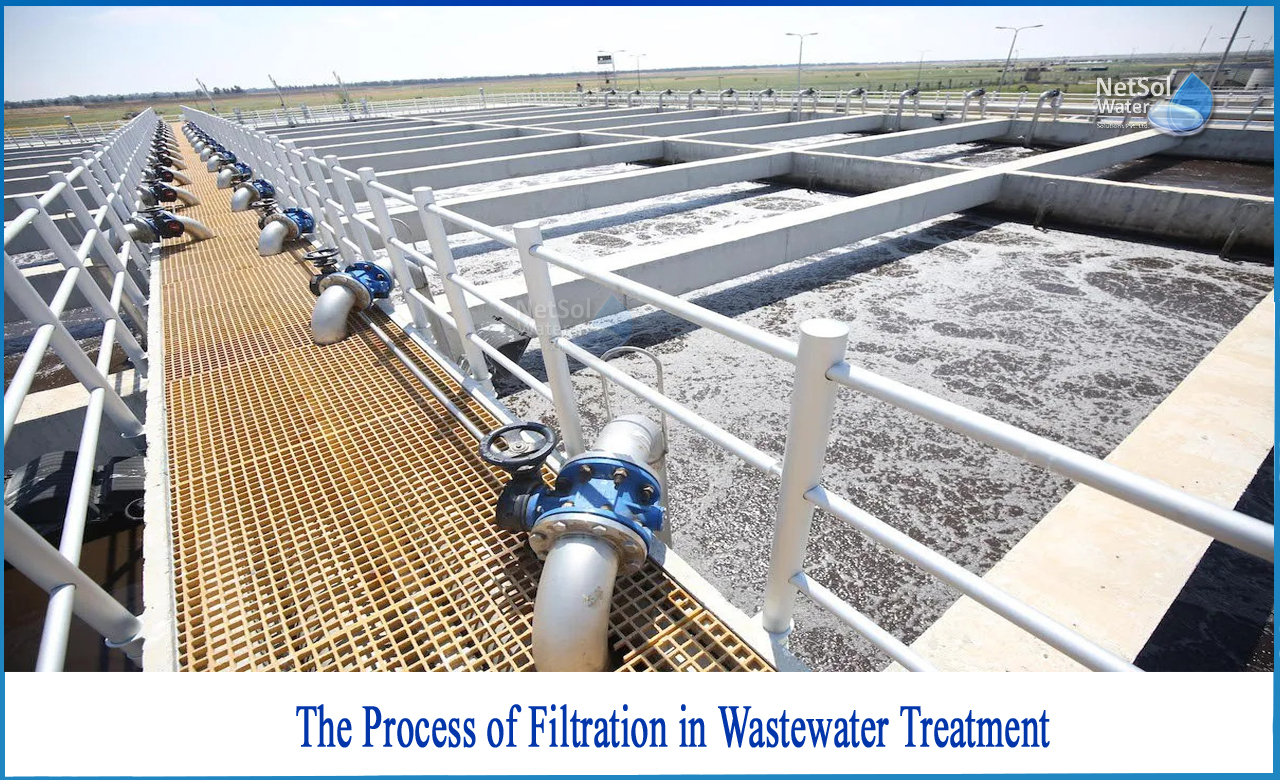

What is the process of Filtration in Wastewater treatment?

Filtration is the process of removing suspended contaminants from a liquid or a gas by passing it through a porous membrane that traps the particles on its surface or inside its pores.

Filtration of liquids

The suspension travels through a filtration membrane; the suspended particles stay on the membrane's surface and in its pores, while the purified liquid, known as filtrate, is collected behind the membrane. The silt, which has been separated from the liquid phase, produces a continually expanding layer on the filtration membrane surface. It usually comprises of variously shaped particles that are strewn about at random.

The process of filtration with flow equations

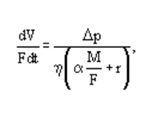

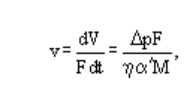

Fresh liquid passes through the layer, before passing through the filtering membrane. In general, liquid flow velocities are modest, and the flow is laminar, as represented by the equation.

Where ‘V’ is the filtrate volume in m3; ‘F’ is the filtration surface area in m2;‘t’ is the duration in seconds; and ‘p’ is the pressure difference in Pa. The terms in parentheses reflect the specific pressure drop for the sediment and filtration membranes, respectively, for a surface velocity of 1 m/s.

Total mass of dry sediment is determined as

………………………… (2)

………………………… (2)

Where ‘m’ is the mass of dry sediment per unit filtrate volume (kg/m3), ‘f’ is the filtrate density (kg/m3), and ‘C’ is the mass concentration of particles in suspension (kg/kg), ‘r’ is the specific pressure drop per unit surface of the filtration membrane.

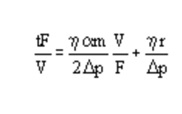

Integration of Eq. (1) at Δp = Constant, yield,

…………………………(3)

…………………………(3)

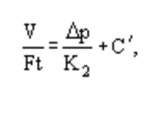

Or, for specific conditions at a constant rate of filtration,

………………………(4)

………………………(4)

Where ‘K2’ and ‘C' are the constants that are particular to these circumstances.

When particles penetrate deep into the filter bed and no sediment forms on the filtration membrane surface, the preceding equations are invalid for separation of finely dispersed suspensions of low concentration by loose fibrous filtration partitions.

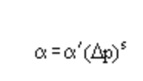

The average specific pressure drop ‘α’ of the sediment depends on pressure drop:

……………………………… (5)

……………………………… (5)

Where ‘α’ is a constant value that depends on particle form and size and ‘s’ is a sediment compressibility coefficient that ranges from 0 to 1.

If the sediment is made up of solid particles, increasing pressure has no effect on their size or packing density, i.e., s = 0, and the filtration membrane's pressure drop is small compared to the sediment layers,

Eq. (1) assumes the form

……………………………. (6)

……………………………. (6)

i.e., the instantaneous rate of filtrate flow is inversely proportional to the quantity of sediment at a constant pressure differential ‘p’.

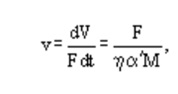

‘S’ approaches‘1’ when the silt is made up of readily flexible particles.

…………………(7)

…………………(7)

i.e., the rate of filtrate flow is independent of pressure at any given time.

These are exceptional circumstances. In reality,‘s’ might range from (0.1 to 0.8). As a result, when filtering a suspension with solid, granulated, or crystalline particles, raising the pressure difference causes a roughly corresponding increase in the flow rate of the filtered suspension.

If the suspension contains mostly flocculent or clay particles, raising the pressure differential has essentially little influence on the flow rate. If a specific critical pressure drop is surpassed, certain sediments are crushed, and the rate of filtrate flow is lowered.

How is filtration improved?

To improve filtration, a special filtering substance is sometimes added to slimy suspensions, and clarification is done at a constant rate of filtrate flow (not at Δp = constant), because otherwise a large amount of filtrate-contaminating impurity slips through at the start, causing a rapid growth of the layer and its pressure drop loss.

In reality, it has been demonstrated that it is preferable to begin filtering with a modest pressure difference and progressively increase it as the sediment layer increases. Centrifugal pumps with a steep characteristic function in a similar way.

How is filter capacity boosted?

According to equation (1), the rate of filtrate flow is inversely proportional to the viscosity of the filtrate. As a result, either heating the suspension or adding ingredients to diminish is recommended to boost filter capacity.

In filtering, particle size is very significant. Filtration of fine suspensions results in an increase in‘α’and a decrease in filtration rate. As a result, coarsening tiny particles, such as via coagulation (heating the suspension or adding coagulants), is a beneficial technique.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems by strategically integrating modern treatment technology with practical solutions. We can also provide a good framework of WWT plant along with various filtration units, among other services.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.