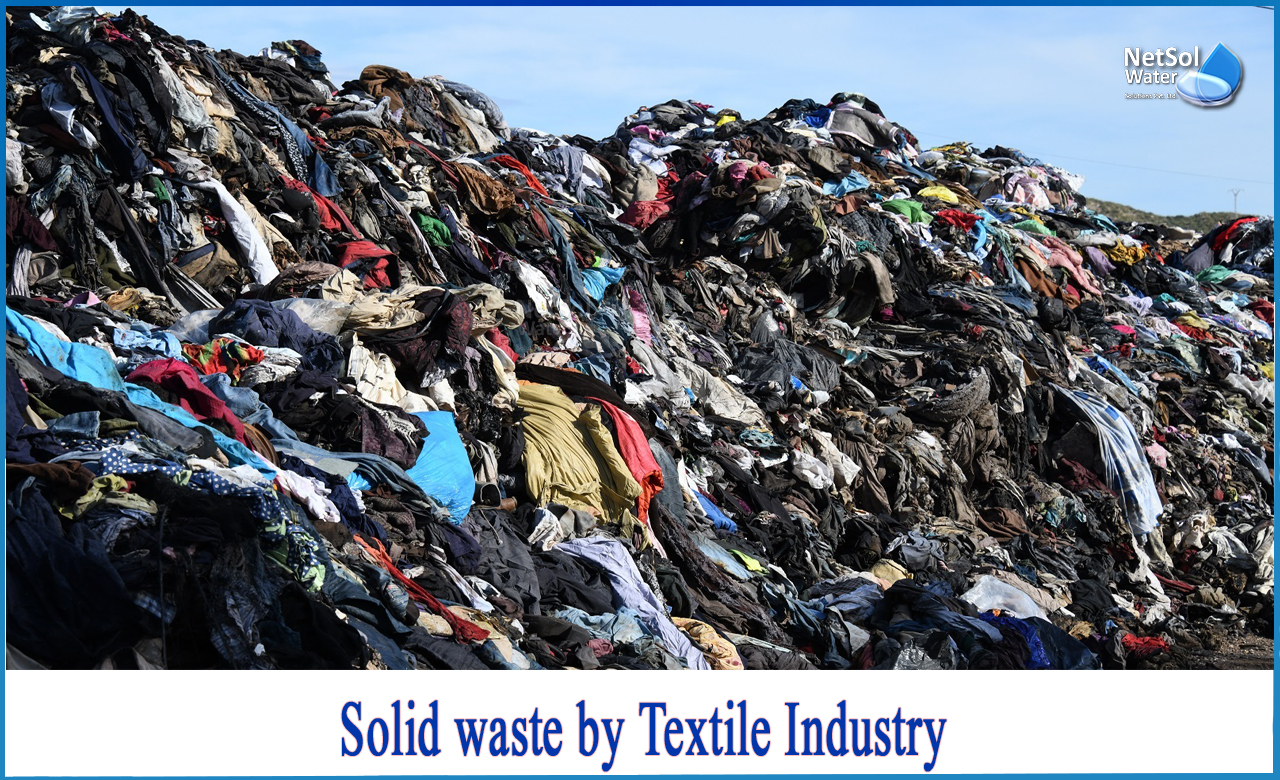

How to treat Solid waste generate by textile industry?

Textile mills contribute to one-fifth of global industrial water pollution and utilize chemicals many of which are carcinogenic. Pollutants emitted by the textile industry do unthinkable damage to the environment. It pollutes the soil, rendering it unproductive and barren in the long term. According to surveys, cotton consumes the most toxic insecticide and fertilizer. The majority of them fall on land and are scattered on crops. Similarly, textile manufacturing plants emit hazardous waste into the surrounding environment and water.

Contamination caused by Textile Industries

1: Water Pollution

Every day, the textile sector consumes millions of gallons of water. A kilogram of cloth normally requires 200 litres of water to wash the fiber, bleach, dye and finally clean the completed product. It also makes use of chemicals and other solvents. Textile effluent mostly results from wet-finishing processes that consume considerable amounts of water and chemicals.

The majority of the colours and chemicals used are synthetic and non-biodegradable. The wastewater created during these operations is very contaminated and harmful and it is released into bodies of water without proper treatment.This disrupts aquatic life as well as millions of humans who rely on water in their daily lives. The solution is to employ our Effluent Treatment Plants to properly treat wastewater from this sector.

2: Hazardous waste

It can take any form–effluents, in water, air, dust, hazardous organic compounds, phosphates, chlorinated solvents, non-degradable surfactants and so on–from diverse operations such as fiber preparation, dyeing, printing, bleaching, and cleaning.

3: Spinning waste

The fibres produced by spinning contain a variety of additional things such as seeds, twigs, dead insects and dust.There are several sorts of wastes at each stage of spinning, such as blow room waste, carding waste, dropping, sliver waste, draw frame waste, ring frame waste and soft and hard wastes.

4: Knitting waste

It is done by hand or machine. It is a difficult procedure, and any flaw in the loop generation approach results in waste. After receiving an order, the merchandiser creates a sample that is used for trials and to confirm closeness. As a result, waste samples are produced. Knitted faults such as stains, bareness, thick and thin yarns, stripes and holes, contribute to industrial knitted waste.

5: Dyeing waste

In the dyeing business, batches with colour variation, crease lines in coloured cloth, and differences in shade from selvage to selvage are often discarded.Clothing waste is produced as a result of several procedures like as cutting, bundling, sewing, finishing, printing, embroidery, and so on. The cutting part generates the most waste of all.

Textile Waste disposal

The majority of this waste is generated by processes such as treatment, transportation, bale openings, service, and housekeeping, which includes:

• Tubing, pallets, cones, containers, and drums

• Corrugated cardboard, plastic wrap

• Sewing and paper waste

• Textile effluent

Conclusion

Textile provides the crucial substance required for living. Even if industry causes pollution, it is a critical transition to a circular economy rather than a linear one. In the previous century, waste created at all phases ended up in landfills. Nowadays, the industry employs procedures such as recycling, revamping, up-cycling, down-cycling, restoring, mending, reusing and decreasing.We inform consumers of their options and strive to become a part of the sustainable chain. Green consumerism is transforming the textile sector, which is now recognized for its efforts to decrease waste and wastewater and that is why, we incorporate eco-friendly techniques.

Talk to one of our advisers at Netsol Water now to discover more about waste management practices and how your company can go greener. Contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.comto remain up to date regarding the latest techniques to enhance your business's waste management.