What is Sludge conditioning and dewatering?

Biosolids temperature, rate of biosolids oxidation, biosolids loading rate, system oxygen needs, biosolids age, and biosolids properties all impact aerobic digestion. By using aerobic bacteria, the method transforms organic sludge particles to carbon dioxide, ammonia, and water while reducing volatile solids, pathogens, and unpleasant order. It can only be used to treat (i) waste activated sludge, (ii) ASP sludge (or trickling filter sludge) and PST sludge, and (iii) waste ASP sludge without PST. It's comparable to ASP, but with a 10- to 12-day HRT.

The oxygen needed for full oxidation of BOD in aerobic digestion is around 2 kg/kg of cells. The ingredients of the aerobic digestion should be carefully mixed to guarantee effective functioning. The bacteria enter a phase (the endogenous stage) during this protracted aeration in which components previously retained by the cell oxidize, lowering the biologically degradable organic matter. Food supplies to microbial life are limited to the point where bacteria begin to devour their own protoplasm, oxidizing it to carbon dioxide, water, and ammonia during this endogenous stage.

What is Sludge Conditioning?

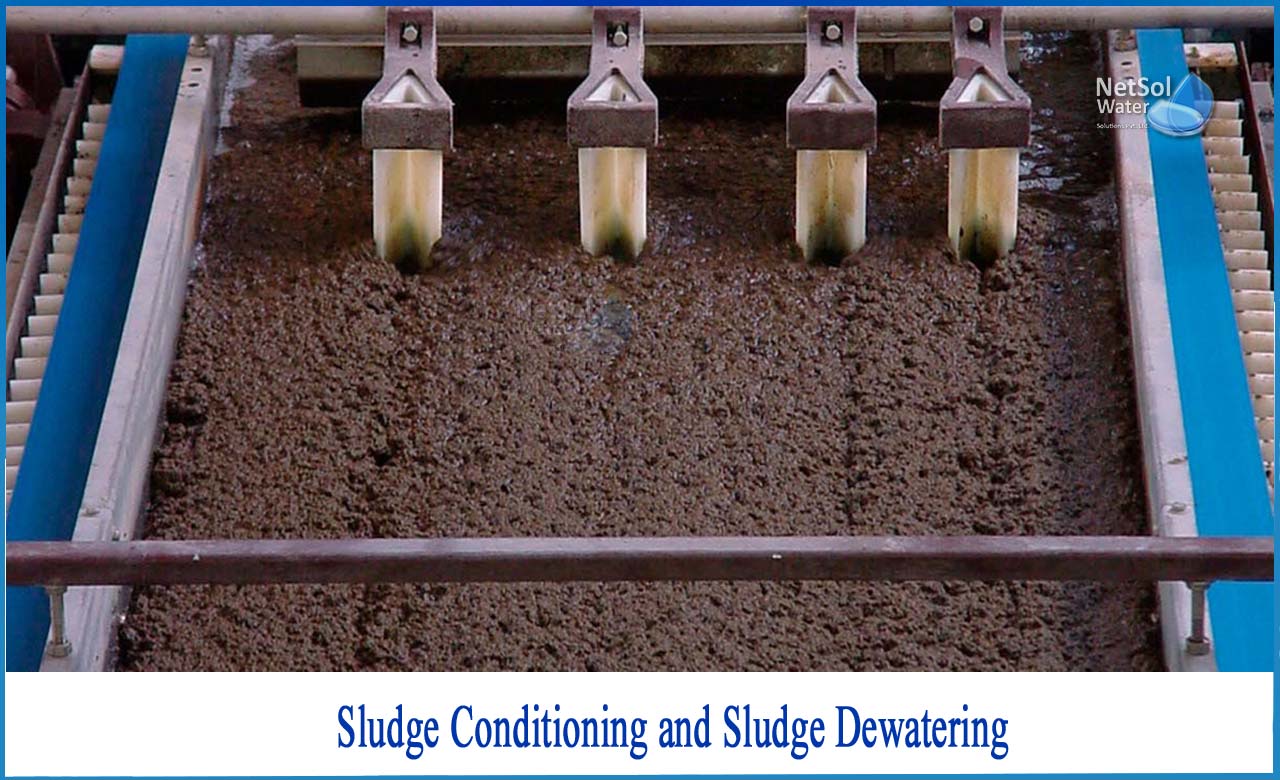

The dewatering properties of sludge are improved by conditioning it. For sludge conditioning, two procedures are typically used: (i) chemical addition and (ii) heat treatment.

Chemical conditioning causes the particles to coagulate and the absorbed water to be released. Prior to vacuum filtering and centrifugation, conditioning is utilized. Ferric chloride, lime, alum, and organic polymers are among the chemicals employed. The appropriate chemical dose is established by a laboratory test. A higher dose is required for sludge that is difficult to dewater.

Heat Sludge treatment involves both stabilization and conditioning. Sludge is heated for a brief time (30 minutes) under pressure (1.0 to 1.4 MN/m2). The temperature is regulated between 140 and 200 degrees Celsius. The treatment causes solids to coagulate, the gel structure to break down, and the water affinity of sludge solids to decrease. As a consequence, the sludge is sterilized, deodorized, and dewatered easily without the use of chemicals using vacuum filters or filter presses. Heat treatment is best for biological sludge’s that are difficult to stabilize or condition by other methods. Equipment's high capital costs often limit its application in large facilities.

What is Sludge Dewatering?

The digestion of primary or mixed sludge reduces the water content to around 90%; nevertheless, treatment is required to further lower the water content. When digested sludge is applied to sludge drying beds, the sludge's water content can be reduced by up to 70%. This process will be hampered if there is too much oil or grease present. Because sludge drying beds require a large amount of land (nearly 40% of the total area required for a sewage treatment plant), other options such as mechanical dewatering on vacuum filters, filter presses, or centrifuges, followed by heat drying or incineration, could be used in places where land is scarce.

Because the environment in most areas of India is conducive to open sludge drying, sludge drying beds are favored as a cost-effective and easy-to-manage option.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.