What is Micro-sand pre-treatment technology?

RO is a method of water filtration process that employs semipermeable membranes that limit the flow of nanoparticles, microbes, and crystalloids while allowing water molecules to effectively circulate in respect to dissolved substances (such as dissolved salts, various harmful minerals, silica, and many organic impurities). Due to this new particular feature, the membranes enable water flow while rejecting water contaminants under the influence of an applied hydraulic pressure and at a pressure difference greater than the osmotic pressure of the source water.

Reverse osmosis (RO) is becoming a more effective and cost-effective form of desalination as new technologies emerge. Using an efficient pre-treatment system to increase the quality of the feed water going through the RO membranes can help your membrane system function effectively.

The worst and most common causes of pre-mature membrane failure

Numerous sorts of solids can cause membrane rupture. Dinoflagellates, generally known as brown algae, are one of the more prevalent causes. Diatoms can be spine-shaped, and the high operating pressure necessary for RO applications might eventually cause them to penetrate the membranes. Algal blooms also inject organic debris into the system, some of which lingers on the membranes and feeds bacteria development. As a result, an environment prone to biofouling is created, which is extremely bothersome and difficult to control, not to mention costly.

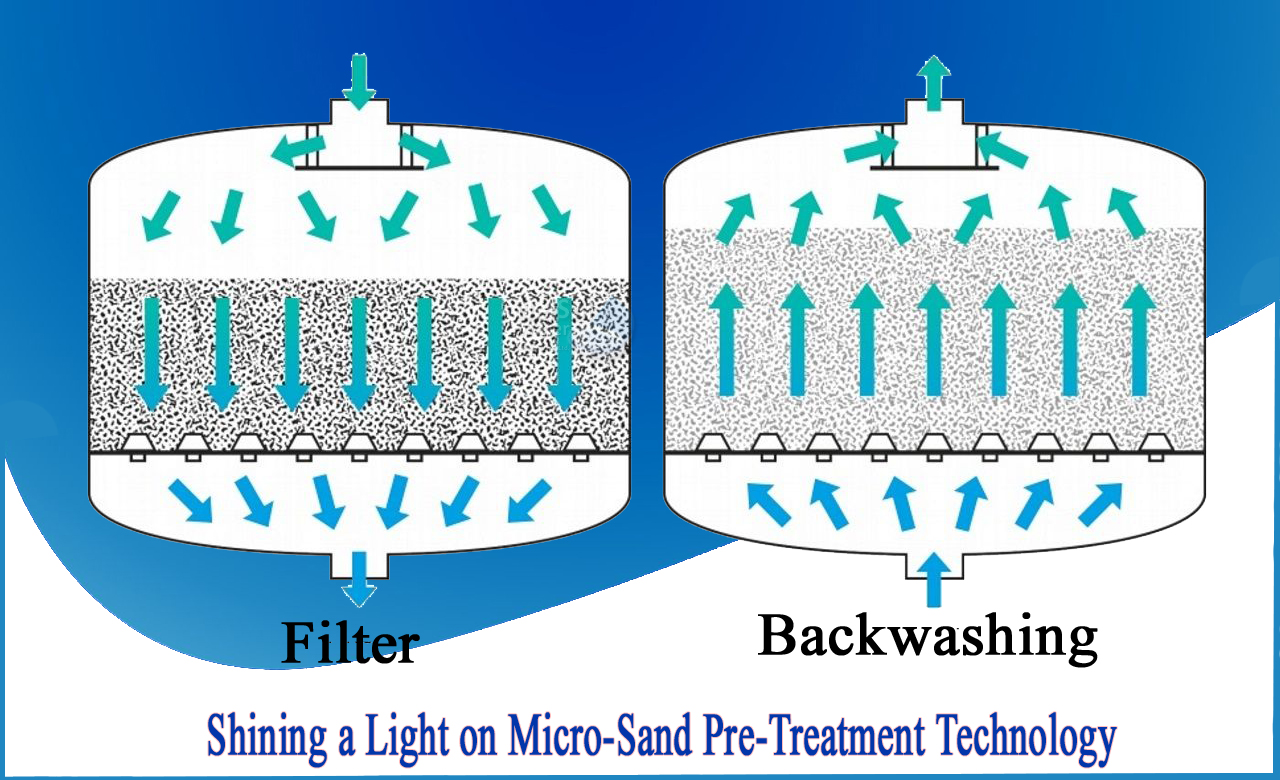

Filtration of cross flow micro-sand

Cross-flow micro-sand filters are made out of pressure containers filled with fine silica sand and utilising cross-flow hydraulics. CMF generally runs at speeds ranging from 30 to 60 m/h while removing submicronic particles. They are pressurised mono-media filters that are used as dead-end filters. What makes this technology so unique is its filtration performance, removing fine particulate down to submicron levels, while providing a small and compact footprint. The technology’s modular design enables the possibility to add multiple units at later date, horizontally and/or vertically.

What distinguishes this technology is its filtering capability, which removes tiny material down to submicron levels while maintaining a small and compact footprint. The modular architecture of the technology allows for the addition of many units at a later date, horizontally and/or vertically.

Micro-sand plays many critical functions in the process

• The micro-sand components' high specific surface area to volume ratio acts as a "seed" for floc formation;

• The high micro-sand concentration within the process dampens the effects of changes in the raw water quality;

•Because the chemically inert micro-sand doesn't really react with the system biochemistry, it may be separated from chemical sludge and reused in the process.

These features, when combined, result in a process that is efficient in the treatment of "difficult" waters, stable in the face of variations in raw water quality, and relatively simple to manage and improve.

Essentially, the use of micro-sand creates chemical floc. that is substantially denser and more lasting than floc produced by traditional clarifying procedures. These flocs have far faster settled velocities than ordinary flocs, allowing for much larger clarifier overflow rates. Higher overflow rates result in lower process volume, a smaller system footprint, and considerable savings in overall civil cost.

Conclusion

Netsol Water is a company that was founded to provide integrated design, fabrication, installation, and maintenance services. We are one of the most dependable water management solution providers. Netsol's water management experts will treat your system and respond to your needs as and whenever required and allows you to focus on what you do best.

NETSOL WATER can customize whatever are the requirements of the customers to provide pre-treatment technology to all the users across the India.