Sewage Water Problem in Noida

Noida is one of the fastest-growing cities in Uttar Pradesh, India. The current population of the city is growing rapidly due to employment opportunities and better connectivity with U.P. and NCR.

Government Sewage Treatment Plants (STP) in the city are not sufficient to treat the complete wastewater/sewage generated from societies and industries.

Due to the high demand for homes, infrastructure, and industries, there is a significant need for water to cater to construction, operations, and various types of industries.

Noida may face a major water scarcity problem in India. Due to the high population in the city, water demand is very high, and the water level is decreasing by 2.0 to 2.5 meters every year.

According to research, Noida is among the top 30 cities in India that will face a major water problem and scarcity, with no drinking water available by 2040.

Due to continuous construction, a heavy population load, and the continuous extraction of water by different types of industries, the water level decreases every year. Drinking water quality is also affected due to improper treatment of sewage water and effluent generated by societies and industries.

If we talk about water scarcity globally, Unicef states that over two billion people are unable to get adequate water, and this number is expected to double by 2025.

As per the data in Noida and Greater Noida, the local authority is treating around 200 MLD (Million Liters per Day) of sewage water every day. They have major sewage treatment plants in Sector-168 with a capacity of 125 MLD, Sector-123 with 102 MLD, Sector-50 with 34 MLD, and Sector-54 with an oxidation pond having a capacity of 9 MLD.

However, Noida Authority's sewage treatment plants are not sufficient to treat the complete sewage/effluent generated by housing societies and different types of corporations and manufacturing industries.

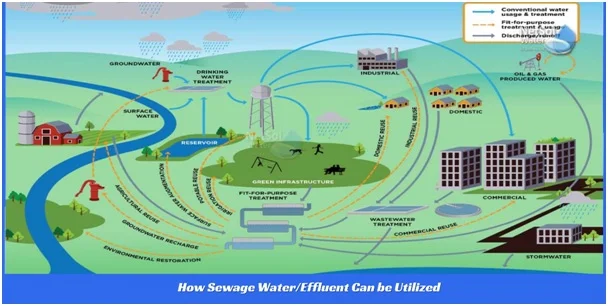

How Sewage Water/Effluent Can be Utilized

Sewage water and effluent can be utilized by treating and reusing them. There are technologies that can help treat sewage water and effluent generated from different types of industries, group housing societies, and manufacturing plants. Treated sewage water can be used for gardening and flushing purposes.

Reusing treated sewage water may help alleviate the water problem and future challenges for water scarcity in Noida City.

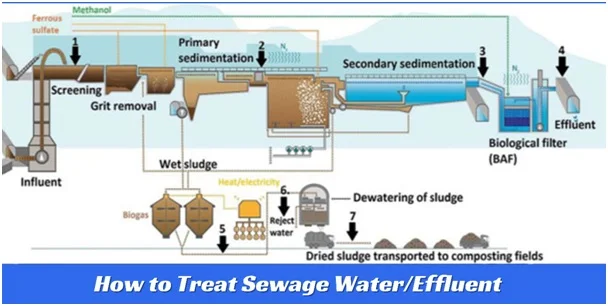

How to Treat Sewage Water/Effluent

Sewage water/effluent can be treated with the help of sewage treatment plants (STP)/effluent treatment plants (ETP). These plants and technologies help treat sewage water up to 98-99%, and the remaining sludge may be used as manure in gardening.

Treated water from sewage treatment plants is full of good nutrients and helps plants and trees grow faster. It is advisable for industries/housing societies to use treated sewage water for horticulture/gardening instead of raw water or borewell water. Using treated water helps reduce the load on groundwater and is better for plants and gardening, helping to avoid future problems of water scarcity.

Countries like Singapore and some Gulf countries are treating sewage water and using the treated sewage water for drinking purposes.

How Sewage Water Treatment (STP) is Useful to Treat Sewage/Sewage Water

Sewage treatment plants have three stages to treat sewage water in three parts: Primary Treatment, Secondary Treatment, and Tertiary Treatment.

Primary Treatment:

Primary treatment in STP helps remove physical components like bottles, polythene, and other physical components from the wastewater. Once physical components are removed, it becomes easier to treat sewage water.

Secondary Treatment (Biological Treatment):

In the secondary treatment, sewage water can be treated with the help of biological treatment. Effective microorganisms help reduce organic impurities from the water, increasing the oxygen amount and improving water quality.

Tertiary Treatment:

In tertiary treatment, with the help of different filters such as carbon filter and sand filter, the color and smell of water can be controlled, and impurities that cannot be seen by the naked eye can be removed.

Sewage treatment plants come in different capacities, starting from 1000 liters per day and going up to 1000 million liters per day and even more. Due to rapid growth in technologies, sewage treated water can be utilized in AHUs, cooling towers, gardening, and flushing purposes. These plants are compact, can be moved easily, installed underground and above the ground. Even parking and gardening can be done above the underground sewage treatment plant.

Many societies like Prateek Wisteria, Prateek Edifice, Exotica Fresco in Noida have installed sewage treatment plants underground and use the treated water for gardening purposes. Manufacturing plants like Sleepwell Mattress, Nilkamal Furnitures, Exedy India Ltd, Jubilant Biosys, Jubilant Pharma in Noida have installed sewage treatment plants above the ground and underground, using the treated sewage water for gardening and flushing purposes.

Why Should I Install Sewage Treatment Plant/Effluent Treatment Plant in my Industry/Corporate

Many times questions arise in the owner's minds: if they have already paid the authority to manage sewage/sewage water, and the authority already has sewage treatment plants, why should they invest in installing sewage treatment plants on their campus?

Here is what Noida/Greater Noida Authority and UP Pollution Control Board have to say about this: Since government/authority STPs are not working properly and are unable to handle the complete load of sewage water in Noida City, in this condition, you should have your own sewage treatment plant and discharge the treated sewage water from your campus. This will help clean the city and avoid the load on government sewage treatment plants.

How to Use Sewage Treated Water for Flushing

Treated water from all STP technologies cannot be used for flushing; most technologies' treated water may be used for gardening purposes only. If you wish to use STP treated water for flushing, it is better to go for MBR (Membrane Bio Reactor) technology or MBBR and SBR followed by UF (Ultrafiltration Plant)!

Pore size for MBR technology membrane is 0.31–0.57 µm microns.

Treated water passing through MBR membrane is suitable for flushing purposes.

Pore size of Ultrafiltration Plant used after MBBR technology and SBR technology is 0.02–0.05 microns. Treated STP water is also suitable for flushing purposes.

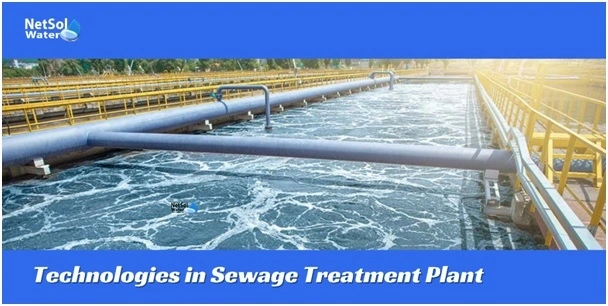

Technologies in Sewage Treatment Plant

Below are the technologies available in India. Meanwhile, among all these technologies, MBBR, SBR, and MBR are being used by most customers and fulfill the requirements of the State Pollution Control Board, Central Pollution Control Board, and NGT (National Green Tribunal)!

- 1. MBBR - Moving Bed Bio Reactor

- 2. MBR - Membrane Bio Reactor

- 3. SAFF - Submerged Aerated Fixed Film

- 4. Underground Sewage Treatment Plant

- 5. SBR - Sequential Batch Reactor

- 6. Green STP Technology

Area Required for Sewage Treatment Plant

The area requirement of STP depends on the technology the user is going to install. For technologies like MBBR, SBR, and MBR (that comply with pollution control board norms), it takes 1 m2 per KLD (Kilo Liters per Day).

For small STPs, the area might be more, and for middle-sized STPs, the area would be 1 m2 for 1KLD.For larger STPs, the area would be slightly smaller than per KLD.

Example: For a 10 KLD STP, the area requirement will be 14-15 square meters; for a 20 KLD STP, the required area would be 24-25 square meters. For a 300 KLD STP, the area requirement would be around 250 square meters, and for a 500 KLD STP, the area requirement would be around 400 square meters.

Suitable Place to Install the Sewage Treatment Plant

Due to the latest technologies in STPs, it is very easy to find a place on your campus to install the STP. However, it is always advisable to install the plant in the back area of your buildings or in the basement. The placement of these plants depends on the site/building.

State Pollution Control Board Rules/Norms/U.P. Pollution Control Board Norms/CPCB Latest Norms

It is crucial that STP treated water complies with the statutory requirements of the local pollution control board and central pollution control.

The parameters that should comply with your STP plant are:

| SR No | Parameter | Permissible Limit as per UPPCB/CPCB |

| 1. | BOD (Biochemical Oxygen Demand) | 10 Mg/l (Where Mg/l stands for milligrams per liter) |

| 2. | COD (Chemical Oxygen Demand) | 50 Mg/l |

| 3. | TSS (Total Suspended Solids) | 20 Mg/l |

| 4. | pH (Potential of Hydrogen) | 6.5 - 9.0 |

| 5. | Phosphorus | Total: 1.0 Mg/l |

| 6. | FC (Fecal Coliform) | 100-230 MPN/100ml (where MPN/100ml stands for Most Probable Number per 100 milliliters) |

How to Calculate STP/Sewage Treatment Plant Capacity

There are norms/rules by the Central Pollution Control Board/State Pollution Control Board for housing societies, commercial buildings, and manufacturing industries to calculate the sewage water capacity. According to the norms, manufacturing industries should consider 45 liters of water per person per day, while group housing societies should calculate 100 liters of water per person per day.

Example for manufacturing industries/commercial buildings/corporates:

If there are 200 people in any buildings/industries:

200 persons x 45 liters = 9000 liters, meaning 9 KL.

So, the requirement for that industry/building will be 9 KL/day.

Similarly, for group housing societies:

Suppose there are 500 people residing in any group housing society:

500 persons x 100 liters = 50,000 liters, meaning 50 KL.

So, the building requirement would be 50 KL/day.

What is BOD and COD in Sewage Treatment Plant

BOD (Biochemical Oxygen Demand) is the amount of oxygen required to decompose the organic compounds/organic impurities from the water. In contrast, COD (Chemical Oxygen Demand) is the amount of oxygen required to decompose/oxidize the inorganic matter/inorganic compounds from the water.

Cost of Sewage Treatment Plant in Noida

The cost of a Sewage Treatment Plant depends on the technology and the water quality the user is looking for. Generally, advanced technology STPs are available at Rs. one lakh per KL/KLD (Kilo Liters per Day). However, as the capacity of STPs increases, the prices decrease proportionally to the increased capacity.

For example:

- 1. For a 10 KLD STP plant in advanced technology, the cost would be Rs. Ten Lakhs.

- 2. For a 15 KLD STP, it would be Twelve Lakhs. For a 50 KLD STP, it would be Sixteen to Seventeen Lakhs.

- 3. For a 100 KLD compact Sewage Treatment Plant, the cost would be Rs. 25 Lakhs.

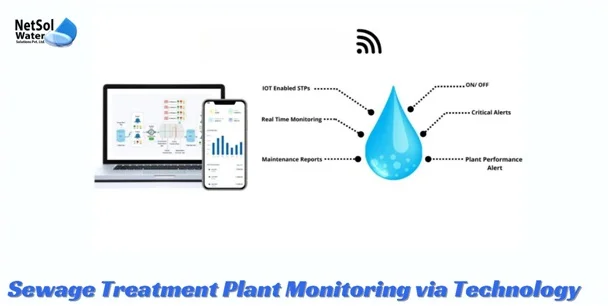

Sewage Treatment Plant Monitoring via Technology

Due to advancements in technology, it is easy to measure the quality of treated water and wastewater. All parameters that fall under statutory norms can be measured easily. There are online monitoring systems, cloud systems that measure data 24x7, 365 days. You can check BOD, COD, pH, FC, TSS, oil, and grease on your mobile or laptop. With the help of electronic sensors, it is easy to measure and control the parameters of Sewage Treatment Plant and Effluent Treatment Plants.

Economic Impact of Sewage Treatment Plant for Industries

It is always advisable to install a Sewage Treatment Plant to save Mother Earth and Mother Nature. Treating sewage water also helps prevent various types of airborne diseases like diarrhea, fever, cholera, and E. coli infection. Using treated sewage water is better for gardening since this water is full of minerals.

Installations of Netsol Water in Different Sectors in Noida - Write a Name of Corporates

Netsol Water is a leading manufacturer of Sewage Treatment Plant and Effluent Treatment Plant and has installed more than 300 STP plants in Noida. Its clients in Noida include Bajaj Energy Ltd., Jubilant Biosis Ltd., Indigo Airlines, Dharampal Satyapal Ltd., Prateek Edifice, Bharath Hindusthan Ltd., Sleepwell, NTPC, Kailash Hospital, NBCC, SHARDA University, Exedy India, Spark Minda, and many more.

Consumables Required to operate Sewage Treatment Plant:

Airblower Oil and Hypo chlorine is required during the treatment of Wastewater in STP plants. Air blower Oil in STP is used as lubricant which reduces the friction of gears and helps to operate the air blower smoothly.This kinds of air blower oil has nature of high oxidation stability .

The process of adding Hypo chlorine in water is known as water chlorination. The main objective of the chlorination is to kills the Bacteria, Viruses, Microbes and other harmful substances from water, thus this process helps to stop spreading diseases like water bones, Chlorea, typhoid, etc.

We are one of the leading sewage treatment plant manufacturers in Noida: For free consultations, you may connect with us.