Sewage Treatment Plant: A Step-by-Step Process

Sewage treatment is a critical process that protects public health and the environment by removing contaminants from wastewater generated by households, industries, and commercial establishments. Untreated sewage can contain harmful substances such as organic matter, nutrients, pathogens, and toxic chemicals, which can pose serious risks to human health and aquatic ecosystems if discharged directly into water bodies.

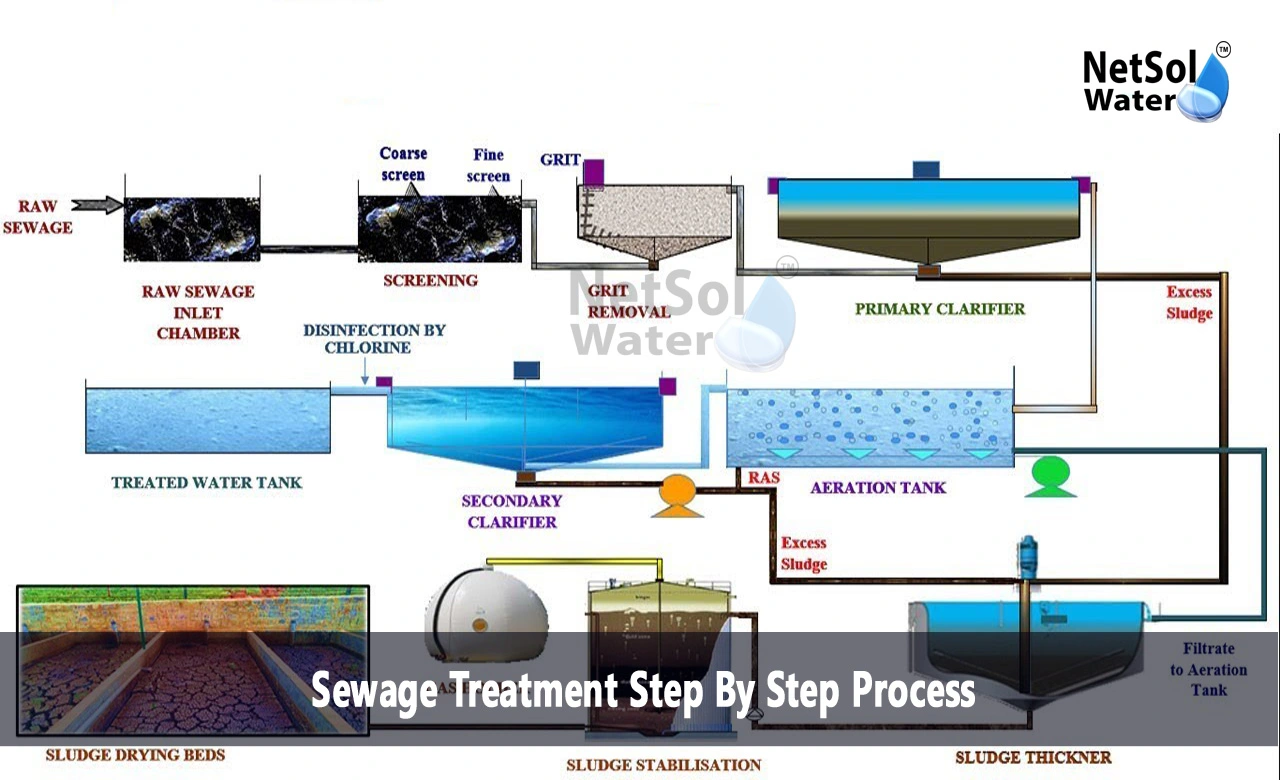

In this blog, we will discuss the step-by-step process of sewage treatment, focusing on the various stages involved in transforming raw sewage into treated effluent that can be safely released into the environment or reused for specific purposes. Understanding the sewage treatment process is essential for municipalities, industries, and communities to manage their wastewater and ensure compliance with environmental regulations effectively.

Step 1: Preliminary Treatment

The preliminary treatment stage is the first line of defence in the sewage treatment process. It involves the removal of large solid objects and grit that could potentially damage or clog downstream equipment and processes.

This stage typically includes the following steps:

1. Screening: Large objects such as rags, plastic, and debris are removed from the incoming sewage using bar screens or mesh screens.

2. Grit removal: Grit chambers or grit cyclones are used to remove heavy inorganic materials like sand, gravel, and grit, preventing them from settling in downstream processes and causing abrasion and wear.

3. Flow equalization: In some treatment plants, flow equalization basins are used to regulate the flow of sewage and prevent hydraulic overloads during peak periods.

Step 2: Primary Treatment

After the preliminary treatment, the sewage undergoes primary treatment, where a significant portion of suspended solids and organic matter is removed.

This stage typically involves:

1. Primary sedimentation: The sewage is directed into large sedimentation tanks or clarifiers, where heavier solids settle to the bottom, forming primary sludge, while lighter materials like oils and greases float to the surface, creating a layer of scum.

2. Sludge and scum removal: The primary sludge and scum are collected and transferred to sludge treatment facilities for further processing or disposal.

Step 3: Secondary Treatment

The secondary treatment stage is designed to remove the remaining dissolved and suspended organic matter from the sewage. This stage typically employs biological processes that rely on microorganisms to break down and consume the organic matter. Common secondary treatment processes include:

1. Activated sludge process: The sewage is introduced into aeration tanks, where air is bubbled through the mixture, providing oxygen for aerobic microorganisms to break down the organic matter. The treated water is then clarified in secondary sedimentation tanks, where the activated sludge settles to the bottom and is partially recycled back to the aeration tanks.

2. Trickling filter process: The sewage is distributed over a bed of rocks or synthetic media, allowing microorganisms to grow on the surface and consume the organic matter as the sewage trickles through the filter.

3. Oxidation ponds or lagoons: Large, shallow ponds or lagoons are used to provide extended aeration and biological treatment through natural processes.

Step 4: Tertiary Treatment (Advanced Treatment)

In some cases, further treatment is required to remove specific contaminants or meet stricter effluent quality standards. Tertiary treatment, also known as advanced treatment, involves additional processes that target specific pollutants or provide a higher level of treatment. Common tertiary treatment processes include:

1. Nutrient removal: Processes like biological nutrient removal, chemical precipitation, or ion exchange are used to remove nutrients such as nitrogen and phosphorus from the treated effluent.

2. Disinfection: Chlorination, ultraviolet (UV) radiation, or ozone treatment are employed to inactivate pathogenic microorganisms and ensure the effluent meets microbiological quality standards.

3. Filtration: Sand filters, membrane filtration, or other advanced filtration techniques are used to remove residual suspended solids and improve effluent clarity.

4. Advanced oxidation: Processes like ozonation, hydrogen peroxide treatment, or UV/oxidation are used to oxidize and remove recalcitrant organic compounds and microcontaminants.

Step 5: Sludge Treatment and Disposal

Throughout the sewage treatment process, various types of sludge are generated, including primary sludge, secondary sludge (also known as activated sludge or biological sludge), and potentially tertiary sludge. These sludges require further treatment and disposal to minimise their environmental impact and, in some cases, recover valuable resources. Common sludge treatment processes include:

1. Thickening: Sludge is thickened to reduce its volume and concentrate solids, making it easier to handle and transport.

2. Stabilization: Processes like anaerobic digestion, aerobic digestion, or chemical treatment are used to stabilise the sludge, reduce odours and pathogen content, and produce biogas (in the case of anaerobic digestion).

3. Dewatering: Mechanical dewatering processes, such as centrifuges or belt filter presses, are used to remove additional water from the stabilised sludge, producing a sludge cake with a higher solids content.

4. Disposal or beneficial use: The treated sludge can be disposed of in landfills, incinerated, or beneficially used as soil conditioner, fertiliser, or fuel, depending on its quality and local regulations.

Conclusion

The sewage treatment process is crucial for safeguarding public health and the environment. It involves a series of carefully designed steps that progressively remove contaminants from wastewater, transforming it into treated effluent that can be safely discharged or reused for various purposes.

From preliminary treatment to remove large solids and grit, to primary and secondary treatment for removing organic matter and suspended solids, and potentially tertiary treatment for further purification, the sewage treatment process employs a combination of physical, chemical, and biological processes to achieve the desired effluent quality. Moreover, proper sludge treatment and disposal are essential aspects of the sewage treatment process, ensuring that the solid byproducts generated during treatment are handled in an environmentally responsible manner or converted into valuable resources.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.