What are the Procedures to Handle Solids in STP Plant?

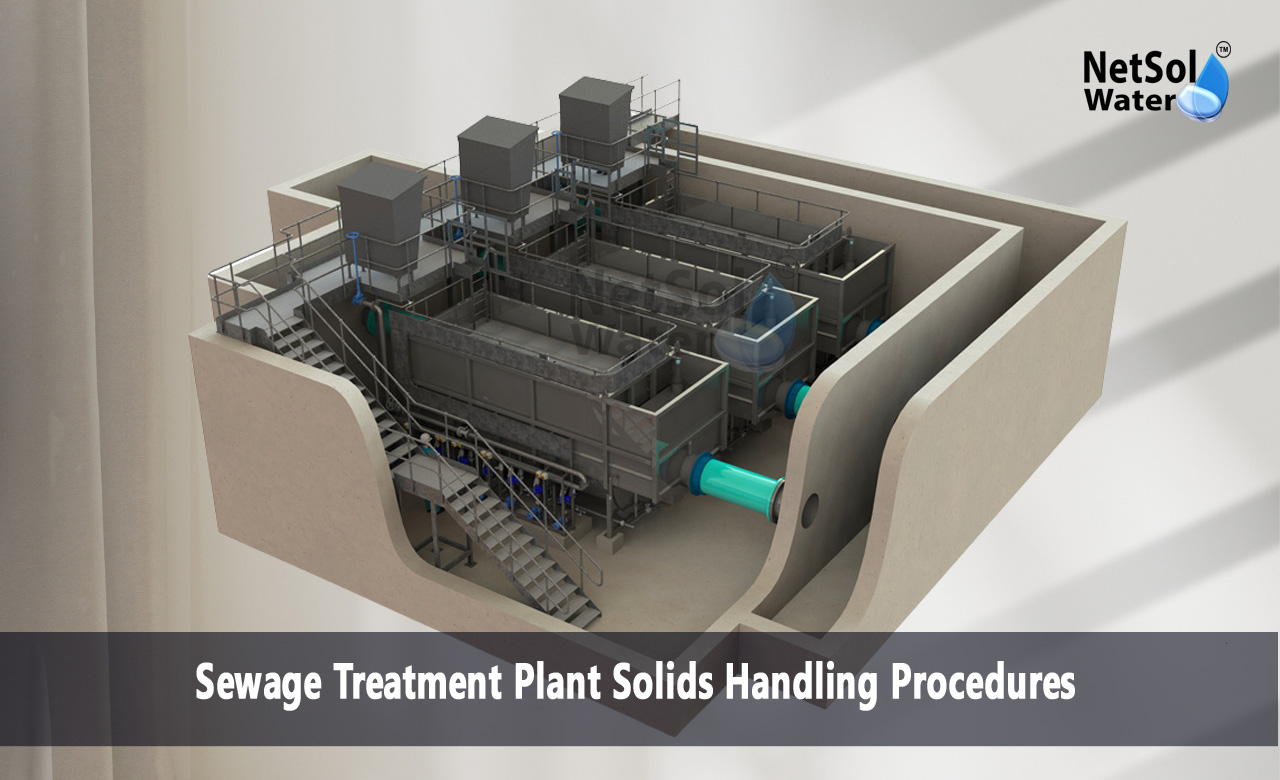

Sewage treatment plants play a big role in managing the wastewater and effects that come with it. It most often focuses on the dealing with the liquid part of the sewage but equally important is dealing with the solids which are present in the sewage. These solid are called sewage or sludge and are major by products of the sewage treatment hence needs to be disposed or reused properly. It is therefore very important that sludge be handled appropriately to ensure that the laid down performance targets in sewage treatment plants are met, without any adverse impacts on the environment.

Where and why Solids Handling is Required?

a. Environmental Protection

The first method which is used in the stated organizations for handling of solids is to protect the environment. When such solids are not treated or inadequately treated they can pollute the soil, water and ground water systems. When sludge is not properly treated properly it may well unload toxic bacteria and chemicals onto the environment.

b. Compliance with Regulations

To prevent pollution, sewage treatment plants are required to meet environmental standards that regulate the treatment and disposal of sludge. These regulations regarding emissions are in force to check pollution and to safeguard health of the people. Sound management of the sludge is required in order to conform to these regulations.

c. Resource Recovery

At times, the sludge can be stabilized and reprocessed into valuable output like fertilizers or bio-energy. This is known as resource recovery and is now turning out to be very common in the modern sewerage industries. Sludge management is critical in ensuring that the maximum possibilities of recycling are achieved.

d. Reducing volumes for disposal

Raw sludge has a high water content consisting of about 98% water which means that a large bulk of the material that needs to be disposed of is water. The solids handling procedures enable solid content in the sludge to be minimized so that the volumes created are manageable and can be easily transported or disposed.

Measures for Handling Solids in Sewage Treatment Plants

The process of handling solids in the sewage treatment plant depends on the following steps, which help in the proper handling of the sludge. These steps include:

a. Screening and Grit Removal

Large debris like plastic, rags, and other non-biodegradable elements are screened out of the wastewater before solids can be processed. In order to avoid damaging equipment later on in the process, grit—a mixture of sand, gravel, and other heavy particles—is also removed at this point.

b. Primary Sludge Collection

After screening and grit removal, the wastewater enters the primary treatment stage, where solids settle at the bottom of the sedimentation tanks. This material is known as primary sludge. It is collected and sent for further treatment in the solids handling process.

c. Thickening

The next process in solids handling is thickening which is the process of concentration of sludge where the water content is reduced. There are three primary approaches used to thicken: Thickening by gravity or dissolved air flotation (DAF) or by centrifuge. The aim in this step is to concentrate the sludge so the volume and the sludge is manageable in the next step.

d. Stabilization

Stabilization is another major step in the management of solids since it kills or reduces the pathogens that may be present in the sludge and lowers organic matter that causes smell during disposal or utilization. There are several methods of sludge stabilization:

· Anaerobic Digestion: It is a process of stabilisation of sludge by microorganisms in a condition where microorganisms cannot survive without oxygen. This leads to biogas which can be used in generation of energy at the same time this will also help to stabilize the sludge.

· Aerobic Digestion: The treatment process which occurs here is not like the anaerobic digestion where the sludge is digested without oxygen. Though it does not generate biogas it has a role in reducing the volume of sludge as well as in stabilization of the material.

· Lime Stabilization: This method involves the use of lime so that to change the ph of the sludge that have ability to kill the pathogen as well as the unpleasant smells.

e. Dewatering

Dewatering follows the thickening and stabilization process in order to get rid of majority of water that is in the sludge. It can be done using belt presses, filter presses as well as the centrifuge. The purpose of dewatering is to change the state of the sludge to more solid like form that can easily be managed, conveyed and ultimately discharged.

f. Final Disposal or Reuse

The treated sludge is then dewatered and the dewatered sludge is disposed in the same ways as those include landfilling incineration, and land application. Any sludge that has been properly treated and stabilised in line with the standard can be used for the production of biosolids for use in agriculture. Energy production as part of Feed ‘n Food production, including biogas production or nutrient recovery, is also included in this stage.

Special Care to Be Taken in Solids Handling

a. Monitoring and Maintenance

Keeping all the machinery and procedures up to date is one of the most important parts of handling solids. Regular maintenance on equipment such as thickeners, digesters and dewatering units is necessary to prevent accidents that could compromise the efficacy of the wastewater treatment plant.

b. Safety Precautions

Sludge handling poses risk to pathogenic agents and different dangerous chemical on the workers handling it. To reduce the incidences of people falling sick, it is advisable to adhere to safety measures, such as using the right PPEs. Ventilation and odor control should also be well addressed to avoid any adverse effects on the workers and the neighborhood.

c. Odor Control

Smell is one of the biggest problems associated with sludge handling, especially during thickening, digestion and dewatering. Measures of odor control include covering of tanks, use of biofilters, or addition of chemicals that could neutralize the bad odor so as not to interfere with the surrounding environment.

d. Energy Efficiency

Thickening and dewatering operations are known to be energy demanding within solids handling activities. Energy efficiency measures can be applied in sewage treatment plants to save energy while at the same time protecting the environment in the course of undertaking their functions.

e. Adherence to Environmental Measures

It is essential to meet the environmental requirement while dealing with sludge. The treatment plants are required to adhere to guidelines set on sludge treatment, disposal and re-use so as not to be penalized or be environmentally threatening. This includes assessing the quality of biosolids intended for land use application and guaranteeing that they are safe enough to be used.

Conclusion

Solids handling is one of the major aspects of the functioning of a sewage treatment plant and should be handled carefully and with due regard to safety issues so that the environment is not affected. Through screenings, thickening, stabilization as well as dewatering mechanisms, the industrial sewage treatment plants can be in a position to manage sludge in a way that will not hurt the environment a lot while at the same time provide maximum chances of recycling. Additional aspects like security provisions, smells, and energy efficiency supplement the efficiency of solids handling.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com