What is MBBR in Sewage Treatment?

Every day, a large amount of wastewater is produced by residences, business entities, and industrial settings. Organic waste in sewage can be difficult to treat since physical and chemical media are ineffective. To achieve effluent limits, biological sewage water treatment methods are commonly used.

However, the performance of treatment plants is being harmed as a result of rising population, urbanisation, and industry. Furthermore, strict municipal and national rules govern the discharge of effluent into the ecosystem and the protection of public health.

MBBR technology is an advanced wastewater technique that may be utilised to increase the efficiency of sewage treatment plants while keeping prices low.

What is the MBBR Technology, and how does it work?

Because of its efficiency and cost-effectiveness, the Moving Bed Biofilm Reactor (MBBR) is a commonly utilised technology. The organic waste is broken down by a microbial population in the biological wastewater treatment process.

It can be performed in one of two ways:

1. The Process of Activated Sludge (ASP)

2. Using a Trickling Filter

Sludge is provided with air in the activated sludge process, which aids in the decomposition of metabolic waste. A system sprays sewage water on a carrier with biofilms in the trickling filter method.

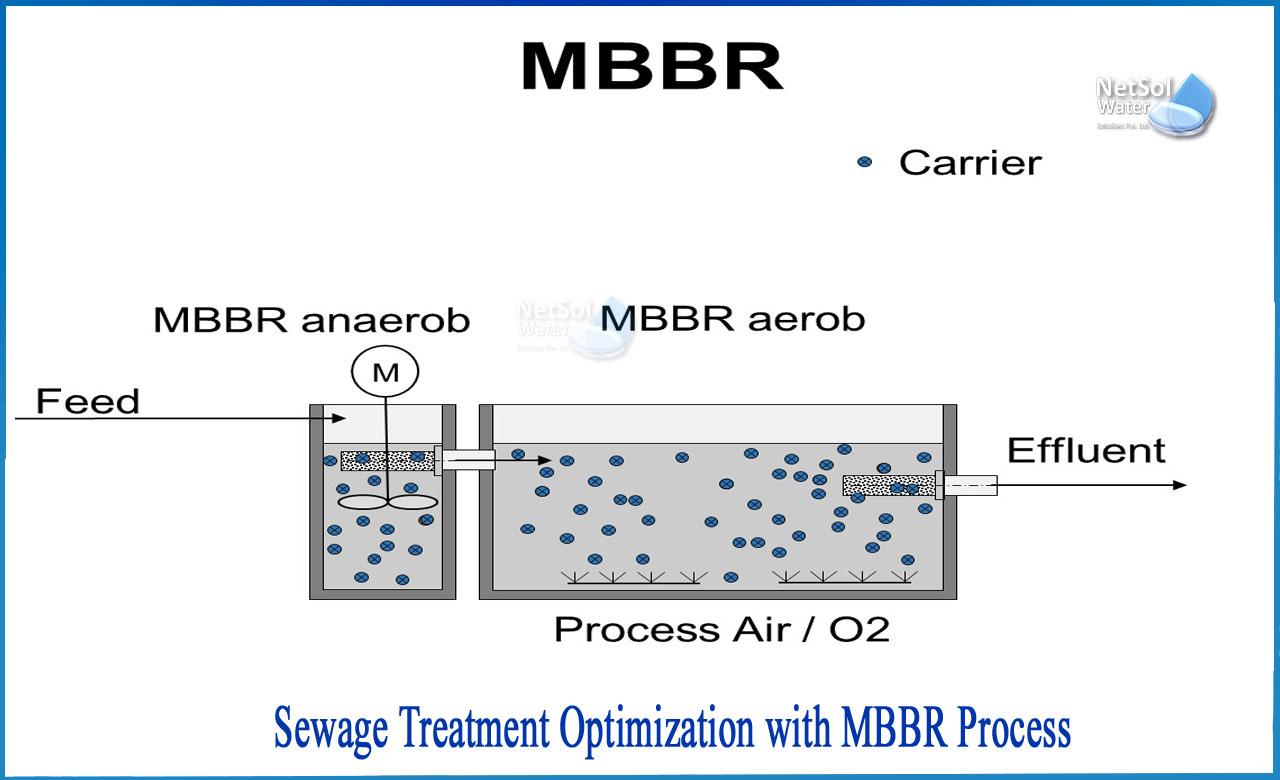

Sludge, aeration tank, plastic carriers, and biofilm are all components of MBBR technology, which combines characteristics of both of these systems. The activated sludge aeration system that collects sludge on plastic carriers, which are then moved around by the aeration process. The carrier's huge internal surface area promotes biofilm growth and improves contact between wastewater, bacteria, and air reducing organic waste.

MBBR Technology Benefits

1: Sludge Retention Time: - Using MBBR has the advantage of not losing biofilm during the process. This is mostly owing to the fact that carriers are maintained inside the rotating reactor. As a result, when compared to an activated sludge process with a suspended growth system, MBBR systems have a longer sludge retention duration. In addition, MBBR enhances sludge settling in the clarifier, and sludge volume is reduced when matched to other biological processes.

2: Hydraulic Retention Time: - The bioreactor's features, such as moving plastic carriers and biofilm concentration, allow it to handle wastewater influent quickly, lowering the hydraulic retention time. In systems with MBBR, HRT takes only a few hours depending on the organic load.

3:Load fluctuation monitoring: - The majority of biological treatment methods necessitate load fluctuation monitoring. Biofilms in MBBR, on the other hand, may adjust to varied volumes and waste loads. It's important to keep in mind that MBBR might not be able to handle a huge load.

4: Compact: - When compared to alternative treatment systems, MBBR units are compact due to the large surface area and low volume of biofilms. This is why current Activated Sludge Systems can readily be upgraded with MBBR. Furthermore, MBBR does not require re-circulation lines or additional piping or pumps.

Conclusion

If your current sewage treatment system isn't performing at its best, it's time to consider MBBR technology. It is critical to improve the treatment process and meet effluent regulations in order to safeguard the environment and human health.

Netsol Water is a renowned company that specialises in all sorts of water treatment plants and is continually developing sophisticated solutions.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.