Introduction

Aeration is frequently used to remove organic materials, during the main and secondary treatment of wastewater. In particular, submerged bubble aeration is successful because it diffuses tiny air bubbles into the wastewater, to help aerobic bacteria break down organic waste.

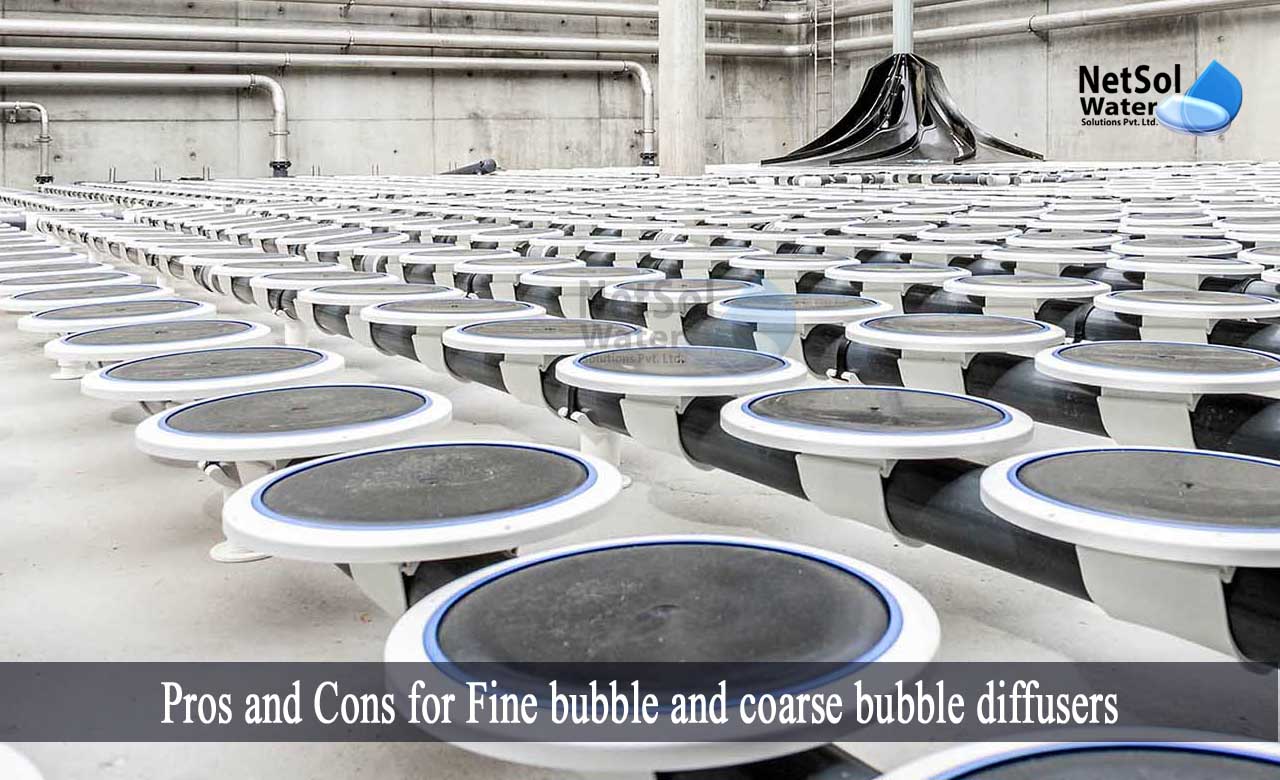

The two varieties of bubble diffusers, however, are fine bubble and coarse bubble diffusers. Your demands and priorities will determine which one is ideal for your facility. Therefore, in this article we will enlist some pros and cons of the fine and coarse bubble diffusers.

What are Pros and Cons for Fine bubble and coarse bubble diffusers?

Although both fine and coarse bubble diffusers use bubble aeration it's vital to recognize some unique aspects of their design and operation, to choose the right one.

What are Fine bubble diffusers?

A smaller-diameter bubble for the aeration process is produced, by fine bubble membrane diffusers. These bubbles typically have a diameter of 1 to 3 mm. During aeration, this fine bubble aeration often offers 2% or, greater Standard Oxygen Transfer Efficiency (SOTE). The dimensions of fine bubble diffusers themselves vary. Our fine bubble diffusers at Netsol Water Solutions are made to operate well, and last long in commercial and industrial settings.

What are Coarse bubble diffusers?

Coarse air bubble diffusers create bubbles with a bigger diameter, to efficiently agitate, churn, and mix the effluent. During aeration, coarse bubble aeration typically produces 1% SOTE or less. To ensure that our durable products, designed to the highest standards, can meet all types of needs, Netsol provides a selection of coarse bubble diffusers at different pricing ranges.

Pros of fine bubble diffusers

A description of some of the qualities that make fine bubble diffusers, an efficient option for wastewater treatment may be found below.

· Efficient Aeration

Standard Aeration Efficiency (SAE) refers to how many pounds of oxygen are added to wastewater, for every horsepower-hour that the blowers power the treatment system, and produce wastewater.

In general, fine bubble diffusers produce at least twice as much oxygen mass, as comparable to coarse bubble diffusers, dispersing more oxygen throughout the water column for more effective aeration. Effective aeration is a great advantage, especially during secondary treatment, when wastewater must be filtered to satisfy the standard of eliminating organic matter.

· Effective Transfer of Oxygen

The Standard Oxygen Transfer Efficiency (SOTE) measures how well the oxygen that has been disseminated, mixes with the water to aerate it. More oxygen can be transferred into the water column, by the employment of a large number of tiny bubbles, such as those created by fine bubble diffusers, than through a smaller number of bigger bubbles.

· Efficiency of Energy

One of the most alluring benefits provided by fine bubble diffusers is energy efficiency, which is also the main factor in their widespread adoption.

The aeration system typically accounts for 50% of the energy needs in a wastewater treatment facility. Any treatment facility that uses an energy-efficient diffuser saves a lot of money, because less electricity is required. In terms of energy consumption, fine bubble diffusers are typically less expensive to run, than other methods of aeration. This is due to the fact that a fine bubble diffuser requires less compressed air, which puts less strain on the blowers that run the aeration system.

Cons of fine bubble diffusers

Although fine bubble diffusers have many advantages, they are not appropriate for all applications. Here are a few disadvantages of fine bubble diffusers:

· Low Alpha Factor

The diffuser's alpha factor describes its resistance to fouling. Because the tiny pores are more prone to becoming clogged with bacteria and organic debris, ultra-fine pore oxygen diffusers frequently become fouled more quickly, than coarse bubble diffusers.

There are various effects of this low alpha factor. First, the sludge accumulation degrades diffuser performance, and lowers the efficiency of oxygen transport. Second, it causes the system to experience back pressure, which could result in the blowers experiencing more damage.

· Weaker Blending

Despite being incredibly effective at aeration and oxygen transfer, the tiny bubbles created by fine bubble diffusers are less effective at mixing. They cannot displace the same volume of liquid that coarse bubble diffusers do, due to their smaller size.

Mixing is essential in wastewater treatment, because it prevents bio-solids from settling in the water and forming sludge, which reduces the effectiveness of the treatment process and requires expensive and time-consuming removal. To get microbes to interact with solid organic materials and break it down, mixing is also important. Less power is used by fine bubble diffusers to aid in this process.

· Complicated setup and clean-up

The entire tank must frequently be dewatered and de-sludged in order to install or clean the diffusers. This requires labour and money for the wastewater treatment facility, as well as time—at least a week per cleaning. Installing diffusers when they are submerged in sewage, might be more challenging and risky in specific situations, where they are attached to floating laterals.

Pros of coarse bubble diffusers

The top benefits of coarse bubble diffusers for wastewater treatment systems, are discussed below:

· High Alpha Factor

The coarse bubble diffusers are less prone to clogging than the fine bubble diffusers, since they have wider openings. The perforations are less likely to become clogged with bacteria and bio-solids. This prevents back-pressure from damaging the blowers, and maintains the diffusers functioning well.

· Solid Blending

Coarse bubble diffusers create larger bubbles that have more volume, move more waste liquid, and hence have more mixing force. Because bio-solids are kept in suspension, undesirable sludge is less likely to form. Due to the intense interaction of waste, bacteria, and oxygen in coarse bubble diffusers, it is easier for organic waste to decompose.

· Easy to Maintain

Larger pores on coarse bubble diffusers make them less prone to clogging, and necessitate less regular cleaning with a pressure washer or manual brush. The treatment centre saves time and money because to this low upkeep.

· Resilience

Greater resistance to fouling results in less frequent wear and replacement of the diffusers. The lighter replacement burden also results in financial savings.

Cons of coarse bubble diffusers

Although coarse bubble diffusers have considerable advantages in terms of their strength and longevity, it's crucial for treatment facilities to take into account their disadvantages, which are covered below:

· Inefficient Transfer of Oxygen

Compared to fine bubble diffusers, coarse bubble diffusers create fewer, bigger bubbles that move more quickly. Less oxygen is transferred into the water column by larger, quicker bubbles. The SOTE of coarse bubble diffusers is typically under 1%. A coarse bubble diffuser would need twice as much air to transmit oxygen, with the same effectiveness as a comparable delicate bubble diffuser.

· Ineffective Aeration

Similar to fine bubble diffusers, coarse bubble diffusers disseminate less oxygen into the water for less effective aeration, often attaining 50% or less of the efficiency attained with fine bubble diffusers, despite their enhanced vertical mixing power.

· Less Effective Energy Use

In general, fine bubble aeration is more energy-efficient than coarse bubble diffusers. The amount of compressed air required to operate a coarse bubble diffuser, places more strain on the blowers and uses more electricity.

Select the appropriate aeration diffusors for your wastewater treatment application

Fine bubble diffusers or coarse bubble diffusers may have obvious advantages, for the work you need to complete, depending on your requirements. You may make a wise decision by understanding how fine bubble and coarse bubble diffusers can be used, in the wastewater treatment process.

Get the best wastewater treatment plantsfrom Netsol Water!

Make Netsol your go-to supplier to reap the rewards of a high-quality system, in your wastewater treatment facility. Advanced hydrodynamics, aeration, media construction, and biofilm technologies, found in our systems improve wastewater treatment processes, lower maintenance requirements, and assist a facility in achieving its specific wastewater treatment objectives.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.