With their activities, many industrial plants and facilities consume or produce wastewater. Depending on local laws and permission requirements, the effluent may be released or reused during their process.

The majority of the time, water must be treated to some extent in order to meet quality standards or legal requirements. This process is known as industrial wastewater pretreatment.

What is pretreatment of wastewater?

Pretreatment is the process by which commercial and industrial facilities treat wastewater, to eliminate dangerous components before discharging it into a sewer system, under the supervision of a publicly owned wastewater treatment plant. You risk paying fines and facing legal repercussions, if you don't properly manage your effluent or treat your water.

Wastewater pretreatment is probably crucial to the quality of your products, aside from avoiding legal penalties.

Netsol Water is aware of the particular requirements for industrial wastewater treatment applications. In contrast to municipal sewage treatment, this treatment requires you to concentrate on the precise procedure that generates the waste stream. The pretreatment techniques are efficient at maintaining your water's quality, and assuring its reuse, even if you intend to recycle the water for your plant's activities.

What are the process of Industrial Wastewater Pretreatment?

An examination of the water quality and the conditions surrounding the discharge, are typically the first steps in the pretreatment of wastewater.

Pretreatment is likely to be followed by a straightforward course of treatment if we assume a generic wastewater, and that the discharge permit's requirements can be met.

Pretreatment aims to get rid of waste substances in the water, like:

1- Solids in suspension and dissolved solids

2- Metals

3- Synthetic substances

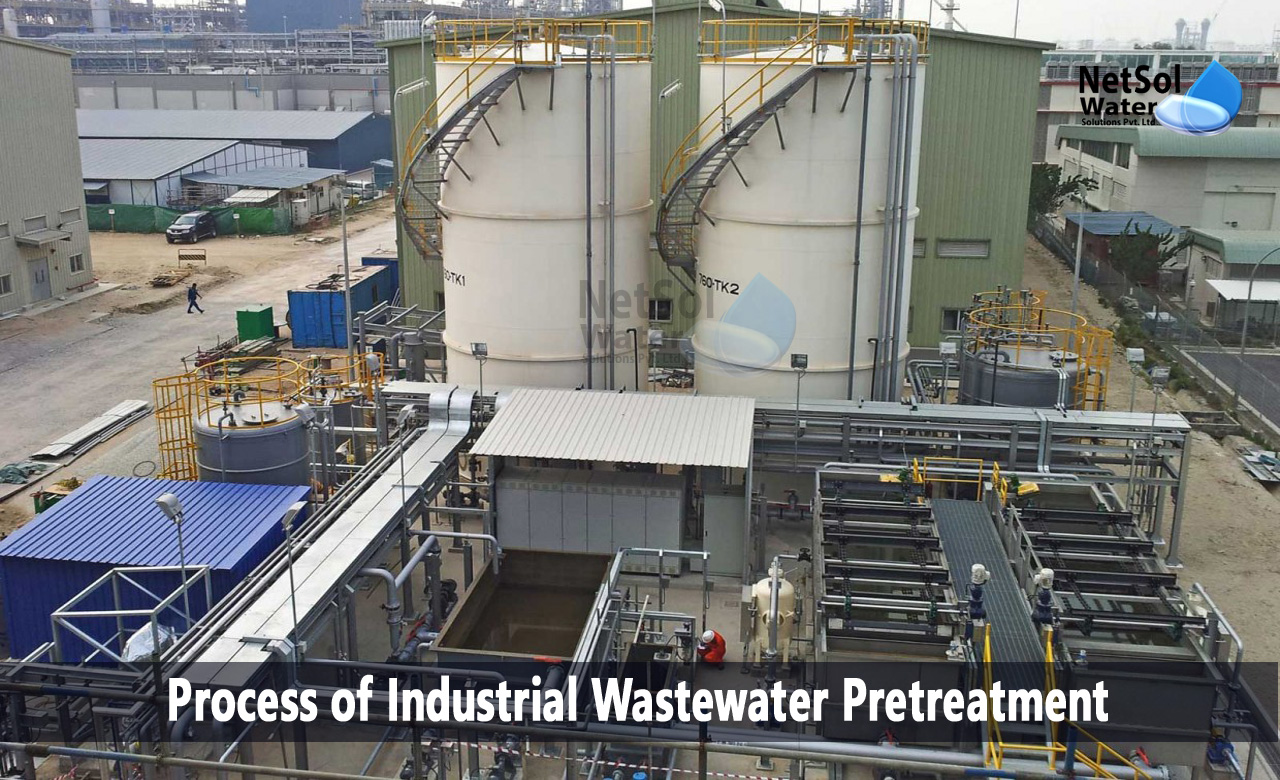

Process of Industrial Wastewater Pretreatment

Finding out what has to be removed from the water in order to meet discharge regulations, should be your first step when thinking about your wastewater pretreatment procedure. Numerous industrial processes produce microscopic materials that are small enough, to pass through mechanical filtration systems. However, you may remove suspended sediments, ions, and other tiny dissolved materials from your water, with the right chemical treatment.

- Chemical pretreatment procedures

The chemical pre-treatments for wastewater or effluent include the following:

1: pH Adjusters

pH adjusters can be used to remove metals and other dissolved pollutants from wastewater. Positively charged metal ions will bond with these negatively charged hydroxide ions, as the pH of the water is raised, increasing the amount of negative hydroxide ions. As a result, a dense soluble metal particle forms, that can be removed using filtering.

2: Coagulants

Coagulants can concentrate suspended pollutants for simple removal in any wastewater pretreatment scheme, which deals with suspended solids. There are two types of chemical coagulants used in the processing of industrial wastewater: organic and inorganic coagulants.

Cost-effective and suitable for a larger range of uses are inorganic coagulants. They work particularly well in applications where organic coagulants are inappropriate, such as any raw water with minimal turbidity. Inorganic coagulants made of aluminium or iron precipitate when added to water, absorbing the pollutants and purifying it in the process. Aluminium sulphate, aluminium chloride, and ferric sulphate are some of the frequently used inorganic coagulants.

The benefits of organic coagulants include lower doses, less sludge production, and no impact on the pH of the treated water.

3: Flocculants

By aggregating pollutants into flakes or "flocs" that float to the surface of the water or settle at the bottom, flocculants, which are used in a wide variety of industries and applications, assists with the removal of suspended particles from wastewater.

They can also be used to dehydrate solids, thicken sludge, and soften lime. Activated silica and polysaccharides are examples of natural or mineral flocculants, whereas polyacrylamide is the most frequent foundation for manufactured flocculants.

Flocculants can be employed alone or in conjunction with coagulants, depending on the charge and chemical makeup of your wastewater. Because, they frequently contain polymers, flocculants differ from coagulants, which typically contain salts.

It is used to "balance" the charge of the water particles in order to induce them to come together and dewater. They can vary in molecular size (weight) and charge density (% of the molecule with either anionic or cationic charges). In general, cationic flocculants may capture organic particles, while anionic flocculants are employed to trap mineral particles.

- Pretreatment with Filtration

Wastewater filtration systems can remove suspended particles and bigger impurities from your water, after chemical pre-treatments. The stage of settling clarification, which makes use of a silo or tank to allow for floating, settling, or dewatering, can come before or after chemical treatment.

Although, there are several methods for removing pollutants, there are three primary categories of mechanical filtration.

1: Centrifuges

Centrifuges are devices that separate solids from liquids by applying force, from a rapidly rotating cylindrical bowl. This quick procedure uses centrifugal thickening and dewatering of sewage sludge, to thoroughly purify your water. The thickening procedure can assist in lowering the volume of storage and dewatering tanks, required by eliminating water.

Dewatering then removes even more water, the concentrate, leaving behind thickened solids, also known as dewatered solids, which can be disposed of separately. Compared to other methods of dewatering, centrifuges take approximately twice as much energy and flocculant to function. The ensuing expenditures may make implementation impossible.

2: Belt presses

Continuous solids dewatering equipment is used in belt filter presses, also known as belt presses, to remove waste. Belt presses dewater sludge primarily using a mix of mechanical pressure and gravity drainage. In a standard belt press, wastewater is initially added to the gravity drainage area, where free water is removed and the slurry thickens.

Here, the concentration of suspended solids in the slurry frequently rises by a factor of three. The press will then squeeze the slurry between opposing belts that are secured in place by a number of rollers, applying a progressively increasing pressure to it. As the belts pass through a number of off-set rollers, each with a decreasing diameter, these rollers shear the sludge.

3: Filter presses

Pump-induced pressure is used by recessed chamber filter presses, to remove solids from wastewater. Sludge is forced under high pressure through filter cloths on a plate in a filter press, until pollutants are removed from the water.

One of the most well-established forms of dewatering machinery is the plate and frame, or recessed-plate filter press, which yields cakes with the greatest solids content of any mechanical dewatering equipment. Typically, their filters are formed of polypropylene squares with a hole in the centre and a concave depression.

Manufacturer of Industrial wastewater treatment facilities

Netsol Water provides a wide range of specialised services, such as design, installation, and commissioning of the industrial wastewater treatment plants, with the pretreatment processes. Our technical team works with your team to help you meet quality requirements, and get the best results.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.