An Overview

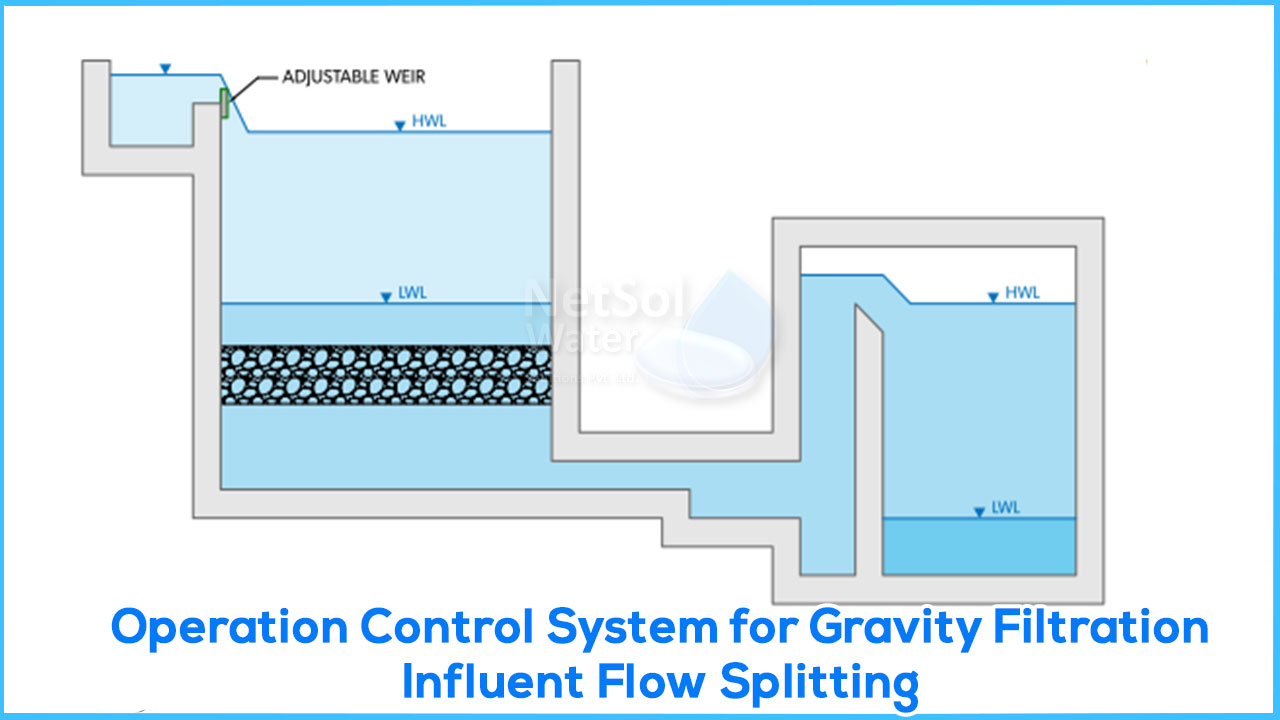

An adjustable weir is located at the entrance of each filter cell in an influent flow splitting filter system. The main component of the system is the influent weir. The water is delivered to the separate weirs by a common feed line or flume that runs through all of the filter cells. The intake weirs can be adjusted so that they are all at the same elevation for uniform flow splitting. An influent control valve and an effluent hydraulic control point are frequently used as ancillary equipment to maintain a minimum water level in a filter cell. If the cell needs to be taken out of service, such as during a backwash, the influent control valve is utilized to shut off the incoming flow.

An equal volume of water is provided to each online filter cell when water passes over the influent splitting weir at each cell. To prevent surface scouring or dewatering of the filter media, an effluent hydraulic control point is added. The hydraulic control point is usually positioned a few inches above the filter media's resting surface. The influent weir flow could be channeled via the wash-water collection troughs to reduce media scouring right after backwash, when dirt head loss and filter cell water levels are at their lowest. The water level within the cell will rise as dirt head loss increases. At a water elevation below the influent weir, terminal head loss occurs.

Pros

- 1. When a cell is turned off, the influent flow to the filter cells is automatically distributed among the other cells in use, with the water level rising over the weirs. For multiple cell operation, the backwash sequence can be altered so that the need to backwash one cell is offset from the need to backwash the remaining cells, preventing overloading of the wash-water recovery systems.

- 2. To keep the system running, no mechanical or electrical components need to be calibrated or modified.

- 3. Weirs are typically placed so that plant operators may visibly inspect them to verify that debris hasn't fouled them. Observing the water level in the cells visually also allows for operability.

Cons

- 1. If the incoming flow exceeds the available online filter area, the filter cell's intended hydraulic loading rate may be exceeded. An increase in flow to the filters, numerous filter cells being offline at the same time, or a combination of these factors can cause this condition. The hydraulic loading rate in each cell will change as the influent flow changes.

- 2. Sudden changes in hydraulic loading rate might cause turbidity breakthrough by dislodging collected solids.

- 3. The downstream hydraulic control point's design is particularly critical to avoid scouring of the media surface, which can result in variances in media bed depth, resulting in unequal filtration rates through the bed.

For any doubt or product inquiry, please feel free to reach us. We can be reached at 9650608473, or feel free to leave your query at enquiry@netsolwater.com.

Netsol Water Solution is a Greater Noida, Uttar Pradesh, India based manufacturer, seller, and supplier of waste and wastewater treatment plant. With the latest and best technology, we are the leader as Commercial RO Plant Manufacturer, Industrial RO Manufacturer, Sewage Treatment Plant Manufacturer, Effluent Treatment Plant.