Odor removal unit for water and wastewater treatment

Odor removal units are a critical component of water and wastewater treatment facilities. These units work to eliminate unpleasant odors that are often associated with the treatment of wastewater.

Here we will explore what an odor removal unit is, how it works, and the different steps involved in this process.

What is an Odor Removal Unit?

An odor removal unit is a piece of equipment that is used to remove unpleasant odors from water and wastewater. These units are typically found in wastewater treatment facilities, but they may also be used in other industries where odors are a problem, such as food processing or petrochemicals.

How Does an Odor Removal Unit Work?

Odor removal units use a variety of physical and chemical processes to remove odors from water and wastewater. The specific process used may vary depending on the type and source of the odor, as well as the quality standards that must be met.

However, here are some of the common steps that are used in odor removal units for removing odors from wastewater:

1. Screening: The first step in the odor removal process is often screening. This involves passing the wastewater through a screen to remove large particles and debris that may interfere with subsequent treatment steps.

2. Chemical Addition: Chemicals such as ferric chloride, aluminum sulfate, or calcium hydroxide are added to the wastewater to neutralize the odor-causing compounds.

3. Mixing: Once the chemicals have been added to the wastewater, the mixture is stirred or agitated to promote the reaction between the chemicals and the odor-causing compounds.

4. Sedimentation: The wastewater is allowed to settle in a sedimentation basin. The odor-causing compounds and other solids settle to the bottom of the basin, and the clear water is decanted from the top.

5. Biological Treatment: In some cases, biological treatment may be used to further remove odors from the wastewater. This involves adding bacteria or other microorganisms to the wastewater that can break down the odor-causing compounds.

6. Filtration: The clarified water is then passed through a filter bed to remove any remaining particles and impurities that may be causing odors in the water.

7. Disinfection: The final step in the odor removal process is disinfection. Disinfection can be achieved through various methods, including chlorination, ozonation, and ultraviolet (UV) radiation. Disinfection is essential to remove any remaining bacteria or pathogens that may be present in the wastewater.

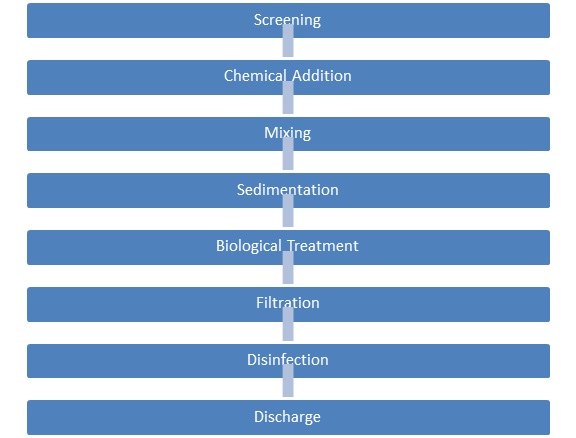

Processes involved in Odor Removal:

The process flow diagram of an odor removal unit is shown below:

In this process flow diagram, the wastewater is first screened to remove large particles and debris. Chemicals are then added to the wastewater to neutralize the odor-causing compounds. The mixture is stirred or agitated to promote the reaction between the chemicals and the odor-causing compounds. The wastewater is then allowed to settle in a sedimentation basin. Biological treatment may be used to further remove odors from the wastewater. The clarified water is passed through a filter bed to remove any remaining particles and impurities. Finally, disinfection is used to remove any remaining bacteria or pathogens that may be present in the wastewater.

Summary:

Odor removal units are an essential component of water and wastewater treatment facilities. They play a critical role in ensuring that the treated water is safe for discharge into the environment. By using a combination of physical and chemical processes, odor removal units are able to effectively eliminate unpleasant odors from wastewater. The specific process used may vary depending on the type and source of the odor, as well as the quality standards that must be met. However, the general process flow diagram described above provides a good overview of the steps involved in odor removal. By understanding how an odor removal unit works, we can appreciate the efforts of wastewater treatment facilities to protect the environment and the health of the public.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.