Overview

Treatment of wastewater is necessary to facilitate protection of environment. Sewage treatment involves two main stages, called primary and secondary treatment, while advanced treatment also incorporates a tertiary treatment stage with advanced processes and nutrient removal. The degree of treatment required depends upon the characteristics of influent wastewater compared to the required characteristics of effluent.

Primary treatment is doneto reduce oils, fats, grease, sand, grit, and settleable solids. This step is done entirely with the help ofmachines.

Secondary treatmentis designed to degrade the dissolved content of the sewage within a biological degradation system, such as activated sludge systems.

The final stage of the multi-stage wastewater treatment process is tertiary water treatment. Inorganic chemicals, bacteria, viruses, and parasites are all removed during the third stage of treatment. The treated water is safe to reuse, recycle, or discharge into the environment after these dangerous substances have been removed. Tertiary treatment is a third degree of treatment that is more advanced option provided to remove total suspended solids and organic matter present in wastewater after secondary treatment.

Need of Tertiary treatment

It is an advanced wastewater treatment option provided to remove total suspended solids and organic matter present in wastewater after secondary treatment. It removes pathogens from treated effluent to meet quality standards. One or more of the unit operations are used in this advanced treatment. Processes involved in tertiary treatment include nutrient removal, disinfection, nitrification, membrane process (Reverse Osmosis), filtration, carbon adsorption etc.

In this article we will discuss about membrane module and its various configurations.

What is Membrane module in Tertiary Wastewater Treatment?

Large membrane areas are necessary for large-scale membrane operations, such as industrial or commercial membrane applications. These large membrane areas are packaged economically into a single operational unit, known as module.

Types of module configuration

There are five main types of module configuration:

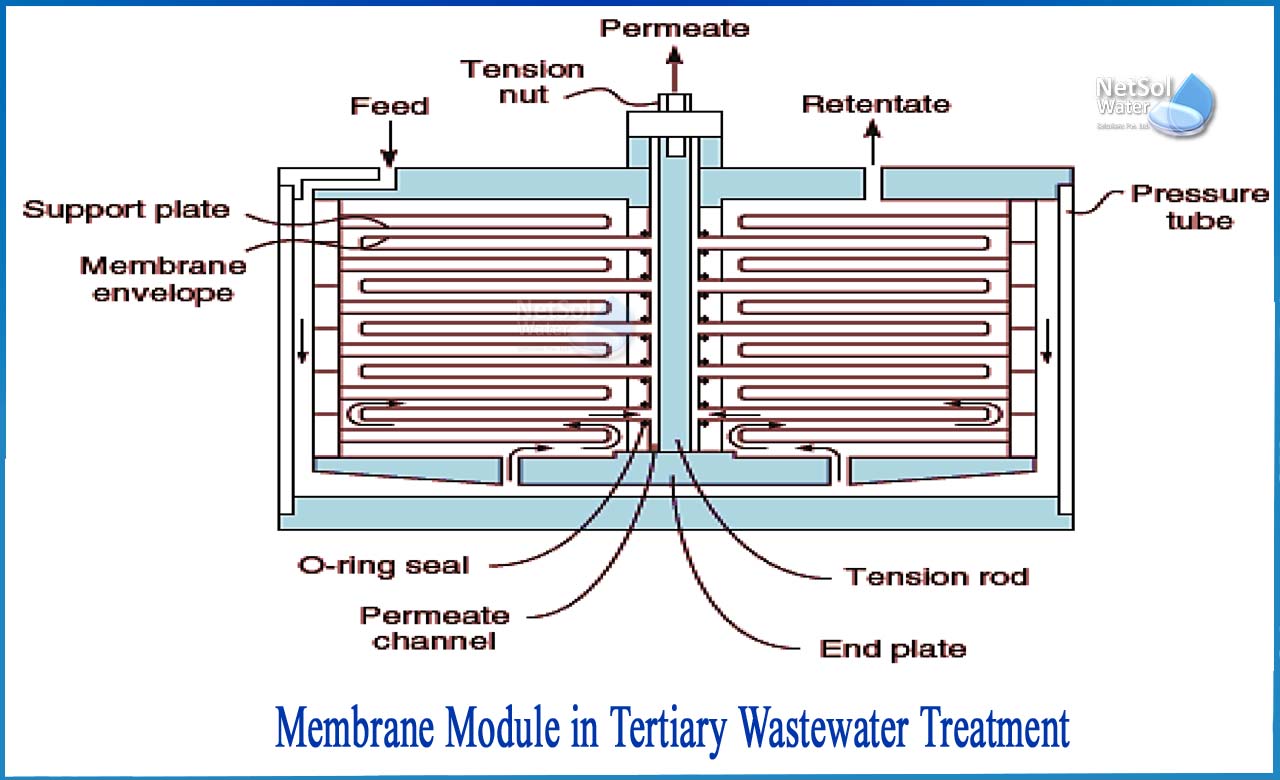

1. Plate-and-frame module

2. Tubular

3. Spiral wound

4. Hollow fine fiber

5. Rotating disc and cylinder modules

1.Plate-and-frame:Two end support plates, stacked flat sheet membranes, and spacers make up the basic arrangement. The membrane is commonly on the inside of a tube in tubular modules, and the feed solution is pumped through the tube. Plate and frame and tubular membranes are not used for municipal wastewater treatment but find their application in food processing plants with high fouling tendency. Feed circulates between membranes of two adjacent plates which provides mechanical support to membrane in addition to the drainage of the permeate.

2.Tubular membranes: Porous tubes with inner diameters ranging from 6mm to 40mm are coated with micro-porous layers of PVC on either the inside or outside walls. Tubular modules, which are made up of individual tubular membranes fitted into a cylindrical housing, can be operated in either an outside-in (wastewater stream flowing outside individual tubes) or an inside-out (wastewater stream flowing inside individual tubes) mode, depending on the orientation of the microporous layer (wastewater stream flowing inside individual tubes). Pre-filtration of wastewater is not required.

3. Spiral wound: The most popular module in industry for nanofiltration or reverse osmosis membranes is the spiral wound module. This module has two flat sheet membrane wrapped around a flexible perforated permeate collection tube. The feed flows on one side of the membrane, parallel to the permeate tube axis. On the other side of the membrane, permeate is collected and spirals towards the central collecting tube. Spiral wound module cannot be used without pretreatment as it is more sensitive to clogging. To provide necessary capacity, the modules are used in parallel and in series to increase efficiency.

4. Hollow fine fibers: Hollow fiber modules used for seawater desalination are gathered in bundles of several thousand hollow fibers in a pressure vessel. They can have a shell-side feed arrangement, in which the feed runs around the exterior of the fibers and emerges at the fiber ends. Hollow fiber modules can also be employed in a bore-side feed system, which circulates the feed via the fibers. Hollow fibers are not always utilized in pressure vessels, as they are in wastewater treatment and membrane bioreactors. The hollow fiber module is the most compact and has the maximum packing density. Fiber bundles can be hung in the feed solution, with the permeate collected at one end of the fibers.

5. Rotating disc and cylinders module: They encourage secondary flows to assist depolarize solute and particle accumulation at the membrane-solution interface. This module has a few disadvantages, including a high energy consumption for rotation and maintenance challenges.

How can Netsol Water help you in this?

Netsol Water is one of the leading water and wastewater treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines which not only turns your wastewater into usable water but also acts as a savior of Mother earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.