How to Integrating Industrial RO Plants with ZLD Systems?

Zero Liquid Discharge has become one of the key solutions of numerous industries due to the lack of water, the intensification of the regulatory environment, and the growth of the quantity of wastewater. Industrial Reverse Osmosis plants are also central to ZLD systems because they recover as much water as possible of the wastewater streams. But the RO cannot bring about zero discharge, it produces a rich reject stream, which is to be treated further.

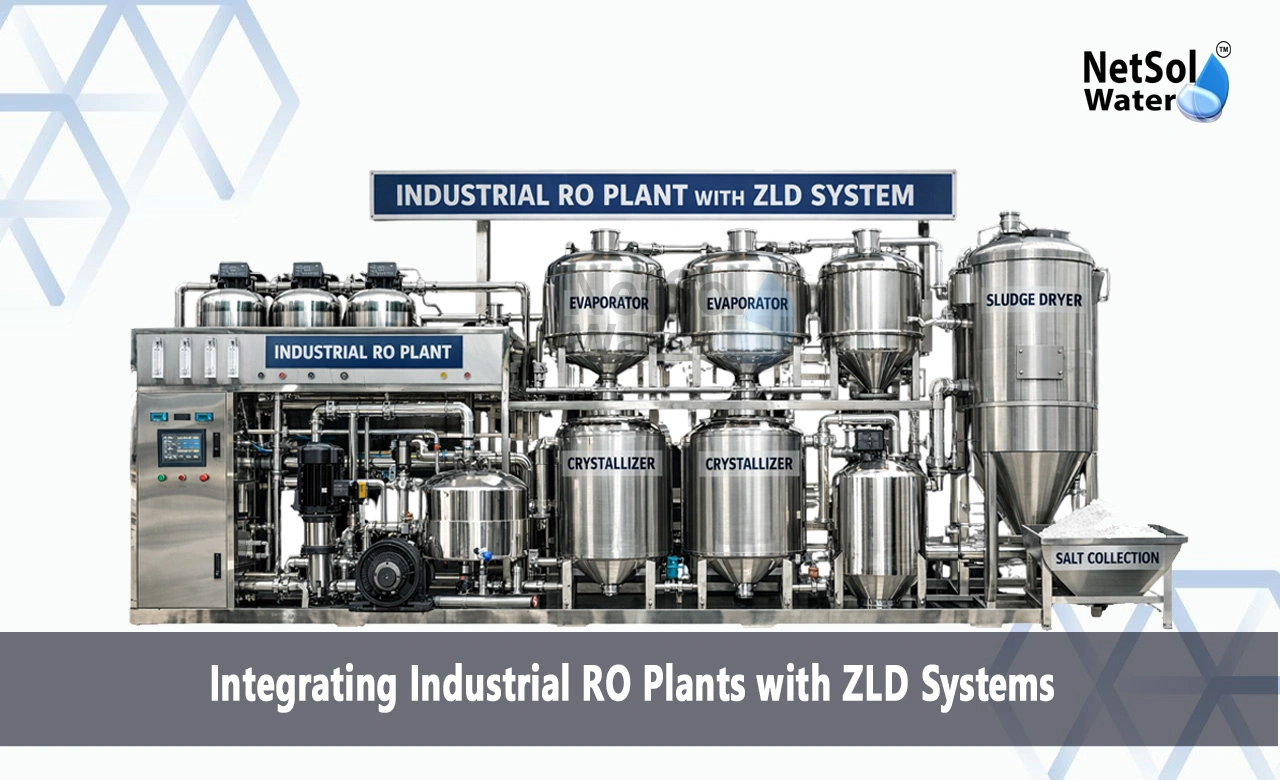

Integrating Industrial RO Plants with ZLD Systems is not just about adding downstream equipment. It needs to be carefully hydraulically designed, water chemistry, and recovery optimum and well integrated with thermal and solid waste management units. When properly implemented, integration enhances better recovery of water, minimizes freshwater reliance, and provides compliance with pollution control standards on a long-term basis.

Function of the Industrial RO Plants within ZLD Systems

ZLD architecture involves industrial RO plants as the main water recovery in the architecture. They treat effluent which has undergone pre-processing and separate them into permeate which can be reused and high-TDS reject.

Within ZLD systems, RO plants:

1· Reuse a huge amount of treated wastewater.

2· Minimize thermal system hydraulic load.

3· Reduced total power usage of the ZLD plant.

4· Enhance use of systems with lower volumes of evaporation.

The effectiveness of the whole Zero Liquid Discharge system mainly relies on the efficiency of the way the RO plant was designed and operated.

Important Design Items of Integration

1: Management of the Feed Water Quality

The quality of RO feed defines the life of membranes, recovery, as well as stability of the system. RO feed used in ZLD applications is normally provided by the biological or physico-chemical treatment processes and may still include silica, hardness, organics and remaining chemicals.

The correct pretreatment includes media filtration, ultrafiltration, and antiscalant dosing so that RO membranes are not damaged, and the operation in ZLD is stable.

2: Optimization Strategy Recovery

The recovery of the RO should be maximized, to minimize the amount of reject sent to evaporators or crystallizers. Scaling, fouling and frequent membrane failure are however, caused by aggressive recovery which is not controlled appropriately.

Intermediate recovery control in a staged RO design means that it is possible to extract more water without damaging the membranes. The target of recovery should be in line with the capacity of downstream thermal systems.

3: Reject Handling and Flow Balancing

There should be a well-regulated RO reject flow that must be combined with evaporators, MEE or ATFD units. Sharp changes in amount of rejected or concentration can cause instability in thermal systems, which cause scaling, foaming, or shutdowns.

Buffer tanks, equalization and flow control automation assist in the harmonization of RO and ZLD components.

Thermal ZLD Systems Integration

1: Multi-Effect Evaporators

Multi-effect evaporators are usually fed with RO rejectin order to reduce the volume. Good integration will also mean that RO recovery will use the minimal load on the evaporator hence decreasing the amount of steam or power used.

Stable RO operation directly enhances and increases the performance of evaporators and minimizes scaling and corrosion related to maintenance.

2: Salt Recovery and Crystallizers

Full ZLD systems take the evaporator concentrate to crystallizers where solid salt is recovered. Purity of salt and purification efficiency of crystallizers is affected by the quality of RO reject.

Lack of integration may result in formation of mixed salts, sticky sludges, and constant blockages. The optimized RO operation will enhance the efficiency in crystallization and allow potential reuse of salt or safe disposal.

Integration Operational Problems

1: Scaling and Fouling Risks

When the recovery operation is high, the amount of sparingly soluble salts in the reject of RO rises. Otherwise, this results in serious scaling of membranes and downstream thermal equipment.

These risks should be controlled by constant supervision, good dosing of chemicals, and the regular cleaning program.

2: Energy Consumption

RO declines the thermal load, and high-pressure operation raises consumption of electrical energy. Poor design may redistribute energy load instead of restricting it.

The energy optimization should take into account the sum of the energy footprint of RO, evaporation, and crystallization units.

3: System Reliability and Downtime

ZLD systems are used as a chain. A collapse in the RO plant will impact directly on downstream units and general water supply.

Redundancy, automation, predictive maintenance are essential to ensure that there is no interruption in operation.

Advantages of Effective Integration

When designed and operated correctly, Integrating Industrial RO Plants with ZLD Systems offers several long-term advantages:

1· Massive decrease in freshwater consumption.

2· Reduced cost of operation of thermal system.

3· Enhanced audit compliance and readiness.

4· Improved system availability and life.

5· Achieved better waste stream control and impact on the environment.

It also provides resilience to industries when faced with the issue of tightening of regulations and water unavailability in future.

Conclusion

Integrating Industrial RO Plants with ZLD Systems is a strategic decision that goes beyond equipment selection. It includes a holistic approach to water chemistry, process design, operational control, as well as lifecycle cost evaluation.

A well-integrated RO-ZLD system will turn wastewater into an asset and will guarantee that zero discharge standards will be observed. Those industries that invest in appropriate integration enjoy enhanced sustainability, stability in operations, and long term economic performance.

With the consistent rise in ZLD applications in various industries, the key aspect of efficient and consistent zero liquid discharging systems will be the optimization of RO integration.

Request Your Free Quote Now. Call our sales team at +91-9650608473 or write to us atenquiry@netsolwater.com. Our team will respond to site queries and arrange a free site survey. We offer detailed proposals with cost estimates delivery timelines and scope of work.