Why is dissolved air flotation important?

Dissolved air flotation (DAF) is a water clarity method that uses air to remove suspended debris from the water's surface. DAF operates by dissolving air under pressure and then releasing millions of small air bubbles into water at atmospheric pressure. This process causes dissolved air bubbles to cling to suspended materials in the water, causing it to rise to the surface and be skimmed off.

The process is typically aided by the addition of a coagulant or a flocculant to the flow water, which increases colloidal particle clustering. DAF is commonly used to clear wastewater from food processing industries, oil refineries, oil fracking operations, chemical factories, and paper mills, to name a few.A powerful DAF system is efficient and can clear large amounts of wastewater in a single session.

Key Benefits and Features

- Reduced footprint — In comparison to any comparable system with equivalent flow rate/loading levels.

- High efficiency - Makes use of sloped settling tubes to improve surface area and speed up separation

- Scouring with air – for automated tube cleaning.

- Whitewater pumps — Rugged pumps combined with saturation tanks give industry-leading dependability and minimal maintenance whitewater (dissolved air).

- Countercurrent scraping - the most effective method of separating sludge from effluent water. Additionally, additional free water can be decanted prior to sludge removal.

- Sludge grating/thickening — Prevents and thickens sludge migration.

What exactly is improved DAF Technology?

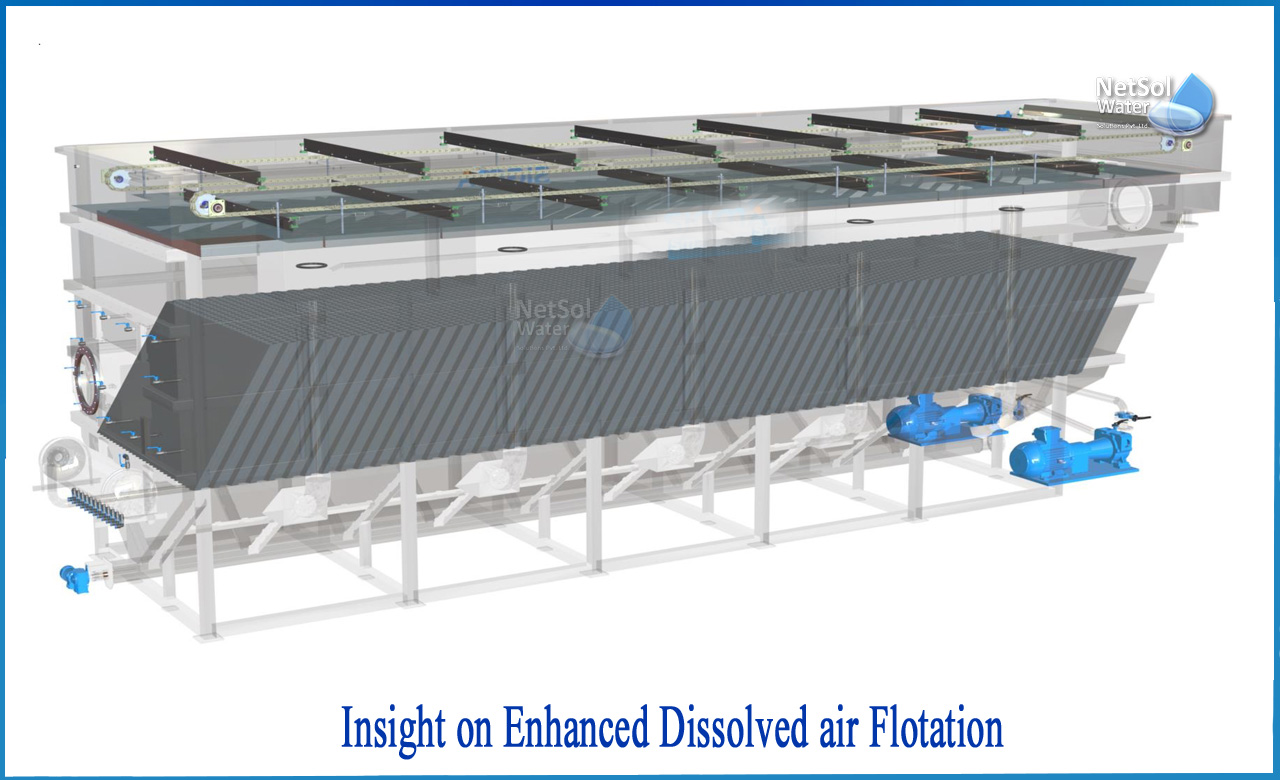

The Enhanced DAF therapy system is a full primary (physical/chemical) treatment method. It is a very adaptable and effective chemical precipitation and physical separation technique. The E-DAF integrates multiple established technologies onto a single platform, including DAF (Dissolved Air Flotation), ACE (Air Charged Entrainment), and DGF (Dissolved Gas Flotation).

How do Enhanced DAF Systems function?

When compared to competing systems with comparable flow rates and loading levels, the Enhanced DAF (E-DAF) System has a lower environmental footprint and impact. This approach will be the most efficient for those who are concerned about the environment. The E-DAF also allows for high-efficiency water treatment, which means faster separation and bigger amounts that can be processed on a smaller footprint.

The E-DAF system employs counter current scraping, which is the most efficient method of separating sludge from effluent water while limiting the risk of contamination to the effluent water. The grating/thickening features of sludge also inhibit sludge movement.

DGF (Dissolved Gas Flotation) is easily modified for refineries and offshore platforms.

-Made of a high-corrosion-resistant material.

-Stairs and a walking mezzanine are included.

-Filters for post-filtration are optional.

-Dewatering system is optional.

Conclusion

Netsol Water Service is one of the most dependable waste management solution providers. Customers tell us how they benefit from Netsol's comprehensive water management systems. Netsol's years of experience and knowledge are inextricably linked with its equipment solutions, testing and monitoring, analysis, and advised remedial measures.

Netsol Water can supply Dissolved Air Flotation (DAF) systems to meet the needs of its customers for the effective removal of Fats, Oils and Grease (FOG), Total Suspended Solids (TSS), and Biochemical Oxygen Demand (BOD) from a wide range of wastewater streams.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.