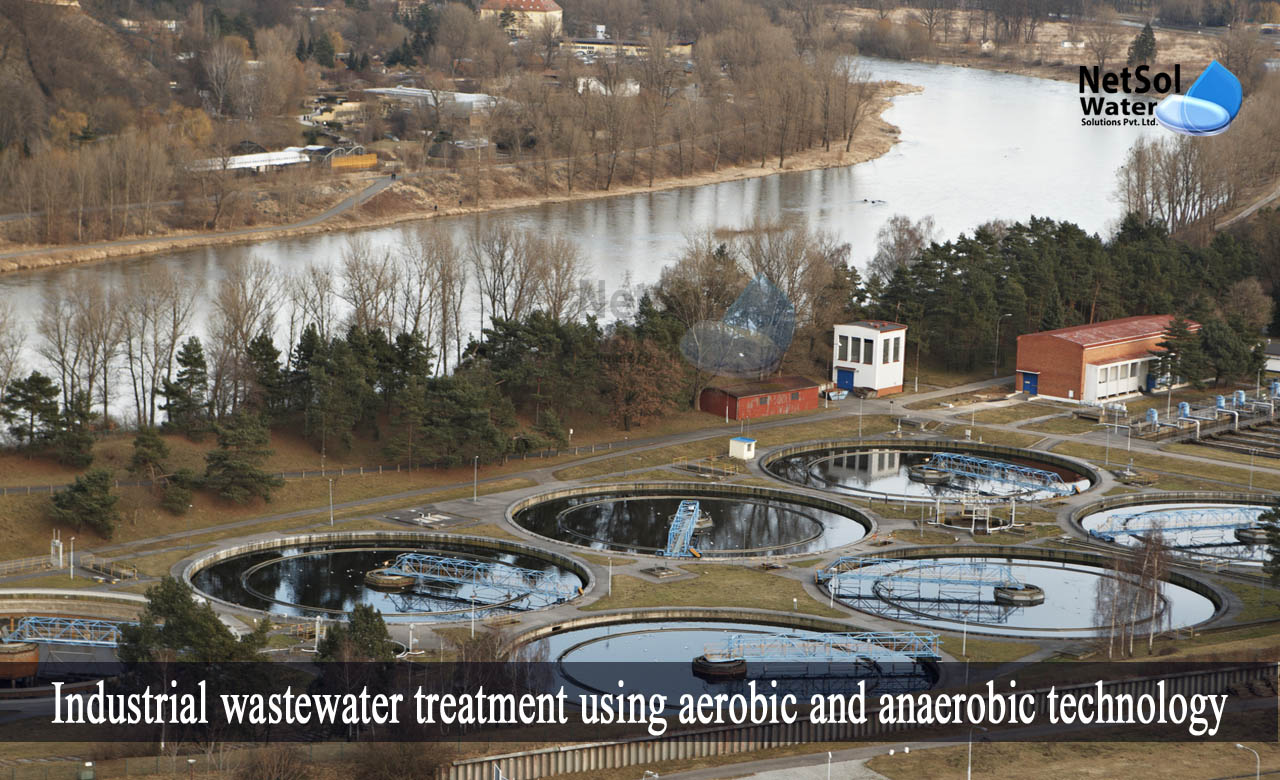

How to treat Industrial wastewater using aerobic and anaerobic process?

The two primary biological wastewater treatment processes that aid in the degradation of organic waste, contained in the wastewater are aerobic and anaerobic treatment.

The usage of oxygen distinguishes the two processes most significantly. In aerobic systems, bacteria function in the presence of oxygen, whereas in anaerobic systems, they function in the absence of oxygen, to carry out the breakdown process.

Continue reading to learn more about the distinctions, benefits, and drawbacks of aerobic and anaerobic treatment methods, for the treatment of industrial wastewater.

Differences between Aerobic and Anaerobic Treatment

The choice between aerobic and anaerobic wastewater treatment is influenced by a variety of variables, including wastewater properties like pH, temperature, and dissolved oxygen, among others. The COD, BOD, treatment time, effluent quality, number of microbes, and energy needed, are also taken into account. For this reason, a number of specialists think that combining systems and technologies can be quite advantageous.

However, the two types of treatment, aerobic and anaerobic have major differences.

Aerobic processes

· When oxygen is required for the effective treatment of the wastewater and the COD is less than 1000 mg/L, the aerobic treatment method is typically used.

· In the aerobic process, organic waste is broken down by oxygen and biomass, into carbon dioxide and water.

· In addition to the breakdown, the nitrification and denitrification processes are used to remediate contaminants, like nitrogen and phosphorus.

· Aerobic treatment produces more sludge than anaerobic treatment.

· Regarding technologies, aerobic wastewater treatment uses the Activated Sludge Process (ASP), Trickling Filter, and Rotating Biological Contactor (RBC).

Anaerobic processes

· Wastewater with a COD of more than 1000 mg/L, which indicates a larger organic content, is treated anaerobically.

· Additionally, in the absence of oxygen, bacteria degrade organic matter and produce by-products, including carbon dioxide, water, and methane.

· Anaerobic wastewater treatment involves the use of Anaerobic Digesters (AD), Continuous Stirred Tank Reactors (CSTR), Sequencing Batch Reactors (SBR), and Up-Flow Anaerobic Sludge Blanket (UASB) Reactors.

Benefits and Drawbacks of Aerobic and Anaerobic Treatment

Due to the absence of methane or hydrogen sulphide production, aerobic treatment offers the benefit of having fewer odours. Additionally, compared to anaerobic treatment, it is more effective in removing nutrients.

Some of the drawbacks include high maintenance expenses and high energy use. Additionally, there is an additional expense for solid waste removal. Methane or biogas is produced during the anaerobic treatment, which has the significant benefit of being a renewable energy source.

Get best manufacturers of industrial wastewater treatment plants in India!

Netsol Water is one of the top businesses offering effective wastewater management solutions. Our advanced wastewater treatment facilities aid in the treatment of wastewater, reducing organics, inorganics, FOGs, TDS levels, heavy metals and other microscopic organisms, with the elimination of unpleasant odours, as well as providing both aerobic and anaerobic treatments for a large number of industries.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.