How to Maintain High-Pressure Pump for Industrial RO Plant?

A high-pressure pump is the most essential component in an industrial RO plant. In it lies the pump that makes up the pressure to force water passing through the RO membranes to get purified. Pump maintenance is crucial to continuous performance, long system life, and avoiding costly lost time. The present post takes you through the basics of high-pressure pump maintenance in an industrial RO plant by offering simple steps and tips on effective care.

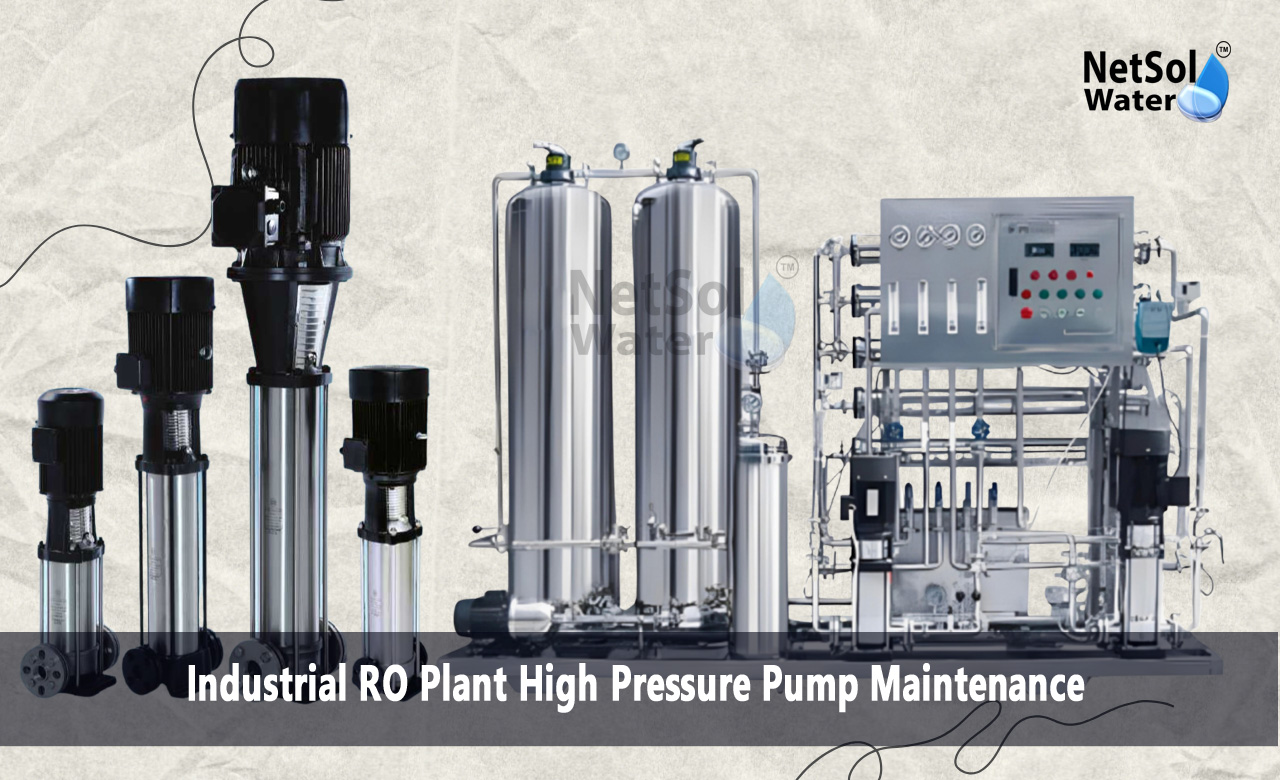

Key Components of a High-Pressure Pump

To maintain the pump in good condition, it is imperative to know its major components. The following are the basic elements that must be monitored on a frequent basis:

· Motor: This is what powers the pump, meaning that the motor must be constantly in operation for the pump to run proficiently.

· Pump Head: Here, the water is compressed to very high pressures before it goes to the membranes. Any clogging or wear in the pump head can decrease the efficiency.

· Seals and Gaskets: Prevent water from leaking out of the pump. The seals wear out after some years of operation and must, therefore, be replaced

· Bearings: Helps to reduce friction and wear in the moving parts of the pump. Lubrication of bearings on regular intervals should be done in order to prevent friction buildup.

· Coupling: Connects the motor and pump, transferring the torsional force. Adequate alignment of a suitable condition of the coupling is required for an efficient operation of the pump.

Common Problem Connected with High-Pressure Pumps

Several problems can be connected with high-pressure pumps in RO plants. Mostly it is caused by poor maintenance. Some of the common problems include:

· Leaks: Worn out seals or damaged pipes cause water leakages, which affect pressure and reduce the plant performance.

· Vibration and Noise: Excessive vibration or noise could be signs of pump misalignment or worn bearings that need to be repaired.

· Pressure Loss: Blockages in the pump, worn internal parts can cause pressure loss within the system.

· Overheating: Insufficient cooling or lubrication can result in pump overheating, which may cause damage to motor components as well.

· Cavitation: This results when there is insufficient water flow into the pump. Bubbly formation and destruction of pump impellers are realized.

Maintenance Procedures for High-Pressure Pumps

Regular maintenance ensures that the pump performs efficiently, and its lifespan is increased. The following procedures ensure that the high-pressure pump is always in good working order in an industrial RO plant.

1. Scheduled Inspection

· Inspect for any leaky signs especially around the seals, gaskets, and connections.

· Look for abnormal vibration or noise of the pump, which may be due to misalignment or wear.

· Examine if the pressure gauge is retaining the necessary pressure at the delivery end.

· Overheating sign does not occur - a hot motor or unusual odors.

2. Lubrication

· Pump bearings need to be lubricated periodically with the proper lubricant to minimize friction and therefore reduce wear.

· Check the pump's oil levels, if applicable, and replenish it or change it if necessary.

3. Replace Seals and Gaskets

Check for wear and damage of seals and gaskets periodically. Replace seals and gaskets the moment leakage or wear is noted to avoid loss of pressure and subsequent leakage.

4. Coupling Alignment

· Ensure that the pump and motor are in good alignment. If it is not aligned, it vibrates, makes more noise, and most of its parts wear out faster.

· Check the coupling from time to time for damage and replace when damaged.

5. Bled and Cleaned

· Cleaning of parts of the pump should be made to ensure free passage and this helps in preventing blockages, especially if such occurrences have been established in feed water rich in sediment or debris. Blockage reduces the performance of the pump and pressure is lost.

· Occasional flushing will help in clearing scale buildup, sediments, and biofilm within the pump and RO membranes.

6. Checking Pressure and Flow Rates

· Checking the pressure and flow rates constantly on both the water being fed into the pump and the output. In case the latter does not match the expectations, a problem with the pump would be indicated, hence requiring some correction.

· If the pump is not pumping well check its membrane and pipes for blockages that may cause restricted flow.

7. Temperature Control

· Ensure sufficient cooling and ventilation for the pump to avoid overheating. Overheating can burn out the motor or pump parts.

· Check if the pump has a cooling system. If so, check the state of the coolant and ensure the coolants level is proper and the system works efficiently.

Diagnosis of General Pump Malfunction

If the high-pressure pump of an industrial RO system fails, the simple steps of troubleshooting follow:

· Loss of Pressure: Ensure that there is no leakage in the seals, clean the inlet and outlet of the pump, and ensure no piping or membrane blockage.

· Vibration Too High: Check if the pump is properly aligned with the motor; check for bearing wear. Lubricate or replace bearings as needed.

· Overheating: Make sure the surrounding has good ventilation; check that cooling system is in proper working condition, and inspect lubrication of moving parts.

· Noisy: Inspect pumps for worn bearings, misaligned components, or damaged impeller. Find loose connections and replace with worn-out parts.

· Water Leakages: Check seals, gaskets, or connection for signs of damage. Replace those parts that have show signs of wear or leakage.

Maintenance Period

This will depend on the operating conditions of the RO plant. Indeed, factors which affect the need for maintenance of a pump include the quality of water being used, the frequency of system utilization, and environmental conditions. Generally, regular maintenance should contain the following services in daily or weekly checks:

· Leakages and pressure readings

· Any unusual noise or vibrations

· Monthly Maintenance: filters must be cleaned, bearings lubricated, and seals and couplings inspected.

· Annual Overhaul: A much more detailed examination of the internal Pump parts is made. In case of any worn or damaged parts, they are replaced.

Conclusion

Maintenance of the high-pressure pump is critical to achieve long-term efficiency and RO plant performance used in an industrial water purification process. Regular inspection, proper lubrication, and timely replacement of seals and other components help avoid common problems such as pressure loss, leakages, and overheating. Maintenance of these operations will save the plant from costly downtime and high-quality water supply through the RO plant.

Proper maintenance of high-pressure pumps is not only a means to prevent breakage but also to realize overall optimization of the performance of the RO plant. Proper operation of the pump ensures its longer lifespan, leading to an increase in the lifespan of the entire system, hence becoming a cost-effective and reliable solution for meeting industrial needs for water treatment.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com