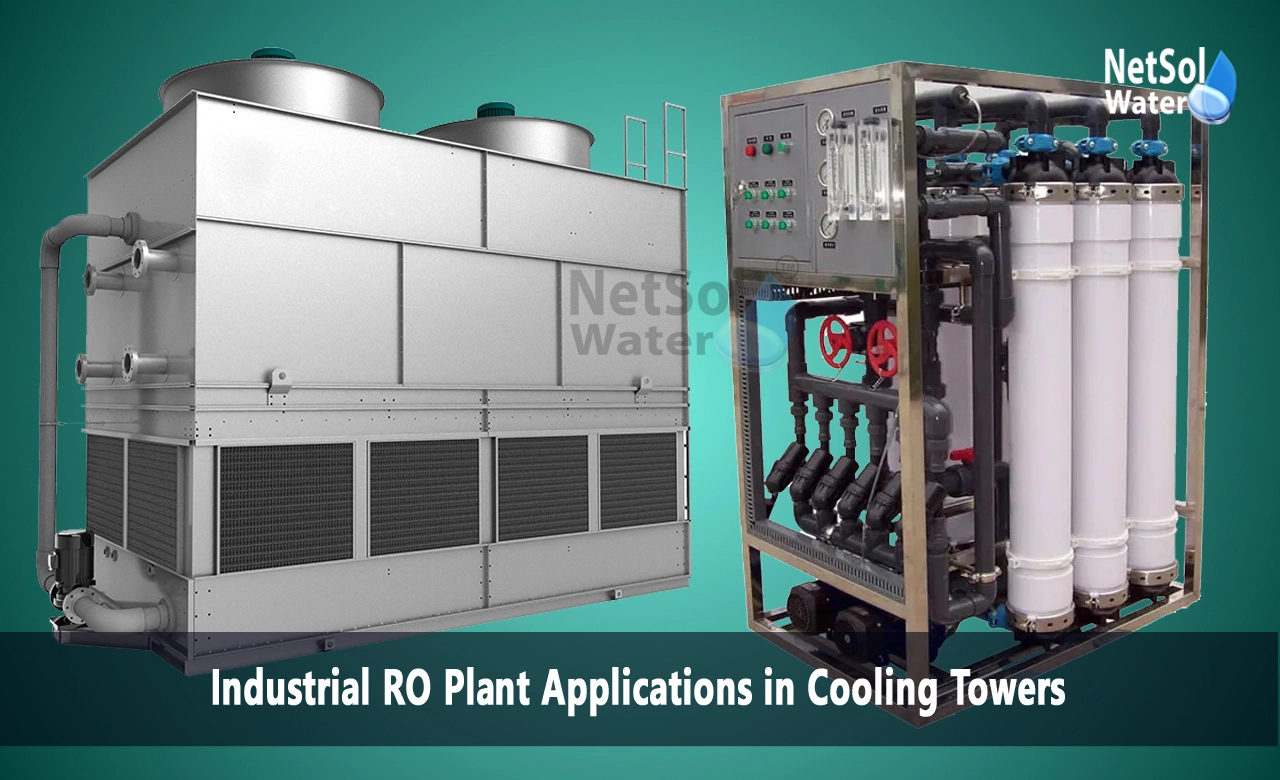

Industrial RO Plant Applications in Cooling Towers

In industries, cooling towers are used in regulating the temperatures of machines and processes in industries. They employ water to cool down their systems to prevent heat building up on the tools that are used in their operations. But the water used in cooling towers has to be of the highest quality if the equipment is to achieve this efficiency and longevity. This is where Industrial RO plants come into play in addressing the problems of high salinity in the management of water. Industrial RO plants help to purify water before it gets to the cooling towers to help remove contaminants on the water.

The Impact of Cooling Towers Water Quality

Cooling towers are commonly utilized in the processes in industries whereby some of the processes have to go through evaporation processes. However, if the water contains impurities like minerals, salts, and microorganisms, it can lead to several problems:

· Scaling: Sometimes minerals like calcium and magnesium deposit and solidify on the surface of cooling tower and equipments as scale. This scale has undesirable effects on efficiency and could lead to adverse consequences in the long run.

· Corrosion: Some of the impacts are corrosion of the metal parts of the cooling tower and other related equipment that comes into contact with the water thus will require replacement which will be quite expensive.

· Biofouling: Cooling tower water also consists of microorganisms such us algae and bacteria which tend to form bio films. These kind of biofilms have lower efficiency heat transfer rate and are also dangerous to human health which leads to diseases like Legionnaires’ disease.

· Water Efficiency: When used water is of low quality, scaling, corrosion and biofouling would demand for more make-up water. This results in a higher consumption of water and therefore high cost of running the facility.

Application of Industrial RO Plants in Cooling Towers

Industrial RO plants are developed with an objective of purifying water and consequently, it can be used for cooling towers. Here’s how they help:

· Removal of Dissolved Solids: This is one of the major tasks that are carried out by an RO plant where probably salts and minerals in dissolved form are taken out of the water. This avoid scaling and the possibility of corrosion in the cooling tower.

· Reduction of Corrosive Substances: An installation of RO plants removes corrosive substances and this decrease the rate of corrosion of the cooling tower and other related equipment. This in turn reduces time and the general costs that are used in maintaining cooling systems hence improving their reliability.

· Control of Microorganisms: The use of RO plants can also help in eradicating microorganisms hence minimizing the probability of biofouling. This assists to maintain the efficiency of the cooling tower and in this way bring assurance of a safe environment.

· Water Reuse: In the case of cooling towers, RO treated water could be recycled and utilized for the purpose, therefore the consumption of water would be low.

Advantages of Cooling Tower With RO Treated Water

Using RO-treated water in cooling towers offers several benefits:

· Improved Efficiency: The use of clean and purified water improves on the efficiency of the heat transfer within the cooling tower so that the fail and other related industrial processes do not get overheated.

· Lower Maintenance Costs: There are reduced problems of scaling, corrosion of surfaces or biofouling due to reduced water contamination by impurities. This results to reduced cost of maintenance and disruption of operations.

· Longer Equipment Life: The resultant water free from impurities also protects cooling towers and associated equipment so increasing their useful life and giving better payback.

· Environmental Benefits: The dependency on water is minimal and in addition, the use of chemicals in the purification process is lowered with the use of RO plants hence making industrial practice more sustainable.

· Compliance with Regulations: Most industries are regulated legally and are required to adhere to the law concerning use and discharge of water. These regulations are met by RO plants which assist industries in providing water for the operation of the cooling towers, which should meet the standards.

Industrial Applications of RO in Cooling Towers

Industrial RO plants are widely used in various industries that rely on cooling towers for their operations:

· Power Plants: Power plants produce a lot of heat and therefore the cooling systems must be effective. The R? plants are used to treat the water to be used in cooling towers and thus facilitate efficient generation of power.

· Chemical Manufacturing: In the chemical industry cooling towers help in controlling the temperature of the reactors and other equipment. The use of RO-treated water minimizes scaling and corrosion, which is crucial for safety and effectiveness.

· Petrochemical Industry: In the petrochemical industry, these cooling towers are important for refining processes in the facility. RO plants make sure that the water being used does not have any contaminants that may cause harm to the equipment or spoil the product.

· Food and Beverage Industry: Cooling towers are applied to regulate the temperatures in the food processing firms. The use of water that has undergone reverse osmosis means that the cooling process does not present any form of impurities into the manufacturing process.

· Metal Processing: Metal processing requires the use of high temperatures, and the use of cooling towers are paramount. RO plants assist in preserving the quality of the water and this prevents the chancing of scaling or corrosion of the equipment.

Challenges and Considerations

While RO plants offer many benefits, there are also challenges and considerations:

· Initial Cost: Industrial RO plant installation may however be costly since a lot of money has to be invested in it. But usually, the costs of maintenance and water are substantially lower in the very long run, which makes up for the initial outlay.

· Energy Consumption: Reverse osmosis systems consume power to run, and power can be expensive raising the operation cost of the enterprise. However they are discovering that new technology is leading to increase energy efficiency in the RO plants.

· Waste Management: While using RO plants, the wastes are concentrated and they are found in a concentrated waste stream which has the impurities. Disposal or treatment of this waste poses a great threat to the environment thus requires proper handling.

Conclusion

Cooling tower make use of Industrial RO plants in order to control the quality of the water used in the process. Their primary role is to minimize the formation of scaling, corrosion and biofouling meaning that cooling systems will run optimally. In addition to equipment durability, RO treated water also leads to longevity of the used equipment and cuts on costs of maintenance thus promoting sustainable operations in industries. As the industries continue to look for ways of increasing their efficiency and minimizing on their impact to the environment, the role of RO plants in cooling tower operations is expected to grow.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com