What is the importance of STP in textile industry?

Every living organism on the planet needs water to survive. It has a transparent hue that takes on the colour of any other coloured substance or material when mixed with it. People can go a few days without eating, but we can't go a day without water. Water is required for drinking, but it is also required for a variety of other activities such as washing, cleaning, building construction, manufacturing processes, and other commercial activities. It is a major requirement in industries to purify water that has been contaminated as a result of their operations. The STP Plant was created to address wastewater concerns in industries.

Wate water problems in textile industry

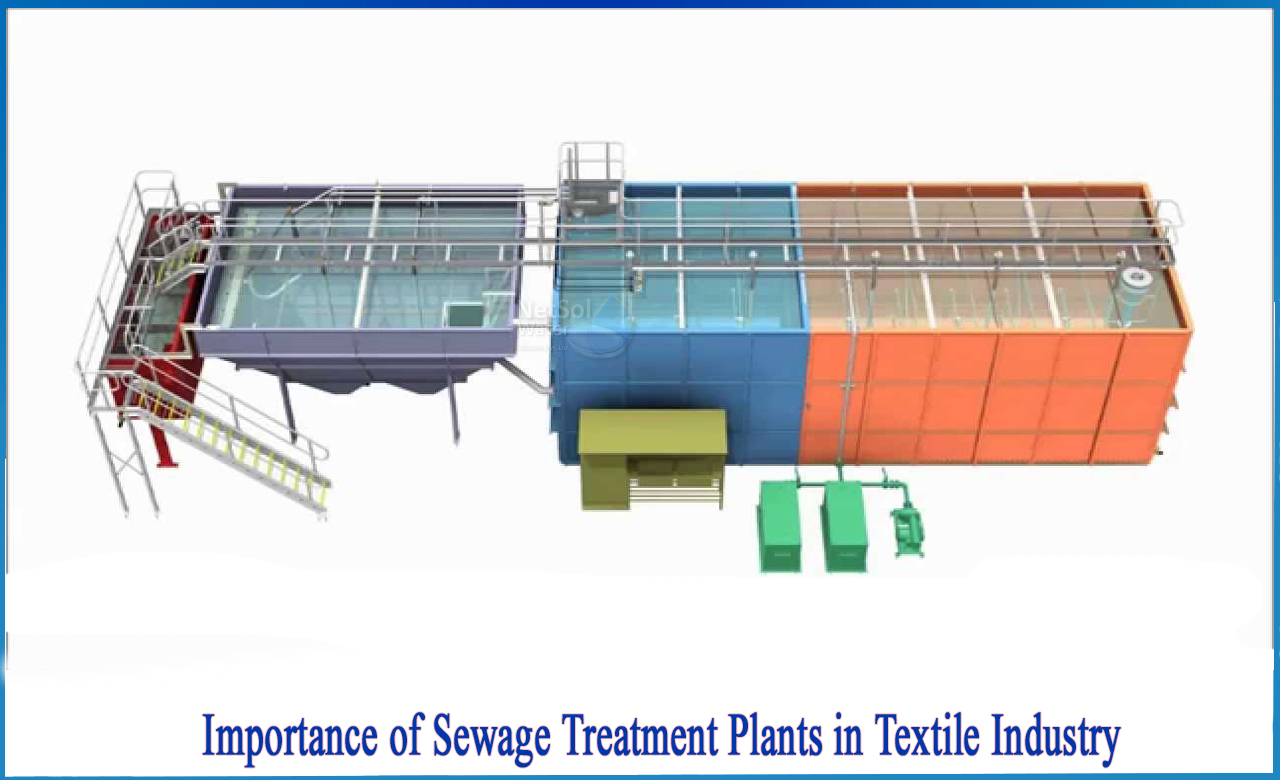

Textile industries use a lot of water in their processes, which resulting in a lot of waste water that needs to be treated before being discharged into the environment. Different sorts of chemicals are utilised in dyeing and other activities in these sectors. They produce wastewater that contains hazardous compounds. To reduce the amount of dirty wastewater, these companies must install a wastewater treatment plant known as a STP Plant or waste water treatment plant for textile Industry. Wastewater treatment is extremely necessary in these industries, and it is also beneficial to them.

Levels of STP/WWTP Treatment

1. Preliminary treatment, often known as pre-treatment, is a physical method of treating wastewater. It entails screening, which involves using bar screens to remove big solids such as rags, cloth, yarn, lint’s, twigs, and other debris that could harm the plant's equipment. The waste water is next exposed to the physical treatment stage.

2. Primary Treatment entails physical and chemical techniques for wastewater treatment. When wastewater is pumped into the primary tank, it remains there for a long period, causing heavier particles to settle to the bottom and lighter particles to float to the top. Flocculation and coagulation are used to remove settled and floatable debris, and the water is then sent to a secondary or biological treatment.

3. Secondary Treatment: Wastewater entering the secondary tank is free of physical particles and is subjected to a biological process. Most WTP’s/ETP’s use biological treatment to remove BOD, which includes aerated lagoons, activated sludge, trickling filters, and oxidation ponds, but the activated sludge process is the most versatile biological oxidation method used for wastewater treatment. Approximately 80% of organic waste will be eliminated here, followed by tertiary treatment.

4. Tertiary Treatment: This stage uses physical, chemical, and biological mechanisms to remove remaining suspended solids, dissolved solids, and other contaminants that were not removed during the previous stages of treatment. Several disinfection agents, such as chlorine, ozone, and UV radiation, are commonly utilised depending on the wastewater quality. After this treatment, the wastewater is ready to be disposed of or reused.

Importance of STP/WWTP in textile industry

• These frameworks use evaporation and filtration to cleanse wastewater and remove dirt, pollutants, and polymers, among other things.

• It entails several treatment steps, including physical, chemical, and biological treatment.

• Its placement in any industry is determined by the amount of wastewater produced.

• The major goal of this system is to reduce significant amounts of wastewater to zero by utilising its unique technique to separate water and salt.

• Its technique eliminates COB/BOD and meets the clean water standard requirement.

• It can verify that you follow all environmental laws and regulations.

• It recycles/converts waste water into clean, safe water that can be reused.

• It is good for the environment because it eliminates harmful pollutants and toxins.

• A well-maintained STP/WWTP will save you money in the long run.

For design, manufacture and installation services for various waste water treatment plants, connect to Netsol Water.