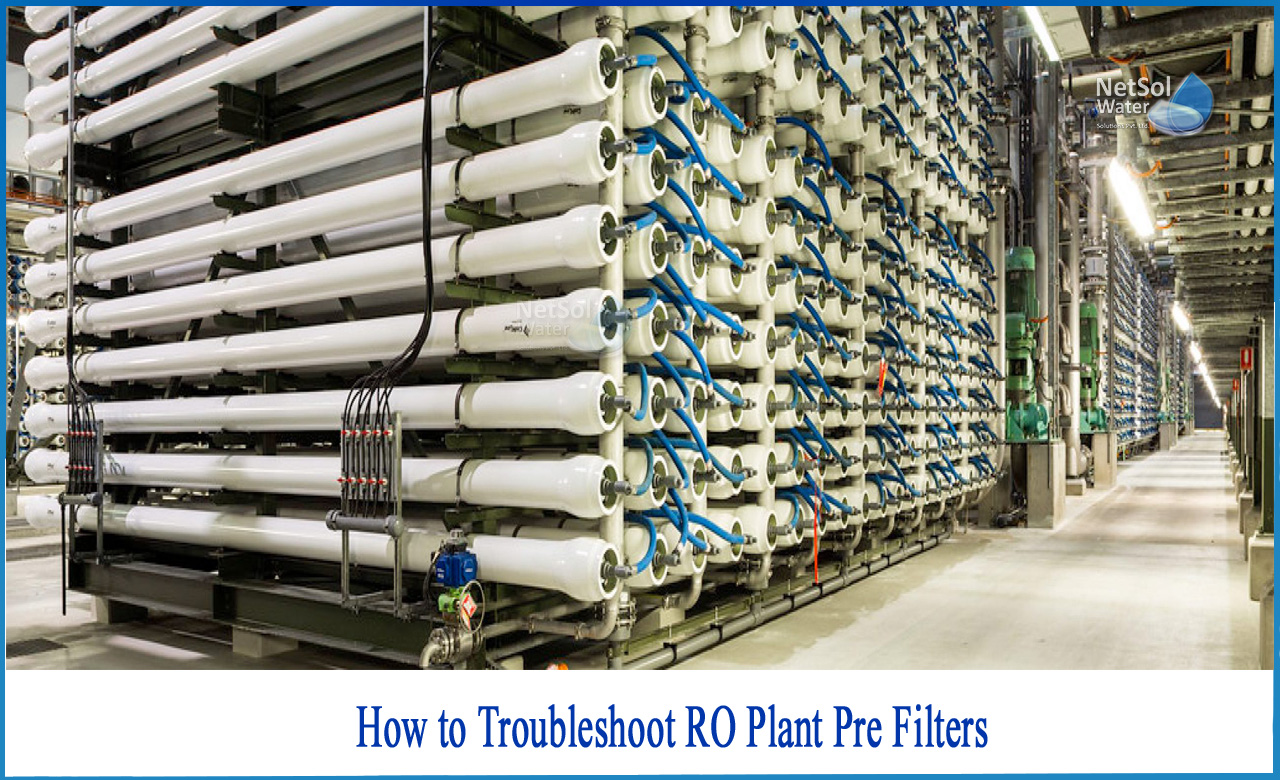

How to Troubleshoot RO Plant Pre filters?

To troubleshoot your reverse osmosis system effectively, you must first determine the source of the issue. Because the numerous components of a RO system work together to generate clean water, a single issue could be caused by a combination of them. To eliminate potential faults, reverse osmosis troubleshooting necessitates a systematic approach.

Here's how to choose the best reverse osmosis system for your needs-

The most typical issues with reverse osmosis systems are

1: There is no water.

2: Water that is either scarce or slow.

3: No shut-off/constant drain

4: A raucous gurgling.

5: Smell or taste.

6: Air gap faucet leaking.

7: A fitting or filter housing leaks.

Key Components of the RO System

1: Prefilters: Prefilters guard against silt and chlorine in the RO system. The flow restrictor might be damaged or clogged by sediments. By oxidizing the membrane material, chlorine can ruin it. On the route to your faucet, post-filters deliver a new pass via carbon.

2: Membrane: The RO membrane is powered by pressure, which is what propels water through the system. Water output and TDS rejection will be minimal without sufficient driving force pressure. The rate of production is affected by input pressure and water temperature.

3: Flow restrictor: The flow restrictor provides resistance to the RO membrane, creating driving force while efficiently metering water flow rate to the drain. It's scaled according to the membrane output rating, and if it's not right, it can cause membrane output to be disrupted.

4: Check valve: The membrane permeate (filtered water) exit has a check valve. The check valve protects the membrane from back pressure while allowing pressure to rise in the tank, causing the valve to open. The RO system will not shut down without it, which could result in membrane failure owing to backflow.

5: ASO (automatic shut-off) valve: This device keeps track of the pressures in the feed and tank. The ASO valve closes hydraulically when tank pressure reaches 2/3 of line pressure, thus stopping water flow.

6: Storage tank: The term "pressure tank" (hydro-pneumatic) refers to the type of storage tank that is utilized with RO systems. There are two chambers in the tanks: one for water and one for air.The separating diaphragm extends into the air side when the tank fills with water, increasing the pressure on that side. The water is pushed back out of the tank and into the faucet or another point of usage by this pressure. Little or no flow at the faucet can be caused by a loss of pre-charge air pressure or diaphragm integrity.

7: Drain saddle: RO systems feature a flow that transports impurities away to the drain. A drain saddle links the waterline from the air gap faucet to the drain line.

8: Air Gap: Backflow prevention is required by plumbing codes on any cross connection (feed supply on one side, drain connection on the other) to prevent drain or sewage water from backing up into the drinking water supply.

9: Feed pressure: The amount of water pressure entering the RO system is critical to its operation. It's crucial to think about how high TDS and low pressure can affect a system's function.

RO Pre-filters Troubleshooting

1: Procedure for backwashing

Before starting the plant, the Sand filter should be backwashed on a daily basis.

1. Open the 2nd and 4th valves.

2. Shut off Valves 1, 3, and 5.

3. Switch to the hand mode on either of the low-pressure pumps (LPP1 or LPP2).

4. After 20 minutes, turn off the pump.

Backwashing should be done as soon as possible afterward.

2: Procedure for rinsing

1. Open valves 1 and 3

2. Shut off valves 2, 4, and 5.

3. Switch to manual mode on any of the low-pressure pumps (LPP1 or LPP2).

4. After 10 minutes, turn off the pump.

5: Begin the operation after rinsing.

3: Procedure for an operation

1. Valves 1 and 5 should be opened.

2. Shutoff Valves 2, 3, and 4.

3. Switch to Auto mode on any of the low-pressure pumps (LPP1 or LPP2).

4. Begin with a high-pressure setting.

5: Pump on autopilot.

What do we offer?

If you want to know more about troubleshooting RO Plant Filters, then you are at the right place!

You can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants (including RO Plants) and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.