How to reduce energy cost by using DAF systems in Sludge thickening?

Dissolved air flotation (DAF) systems are frequently used to extract suspended particles, fats, oils, and grease from a number of wastewaters in a variety of processing applications, including food and dairy, meat, fish, and poultry rendering, and waste vegetable oil applications. DAF systems are also employed in a broad range of applications, including industrial, manufacturing, oil and gas drilling, and marine waste water treatment.

In these applications, fast process speeds, compact footprints, and operational flexibility are frequently advantageous. Micro bubbles are injected into the waste steam by DAF systems, which cling to the particles and float them to the surface, where they are skimmed off. However, one of the most typical problems with a DAF system is the mess, as well as the costs of disposal and processing the waste.

Dewatering DAF sludge with a decanter centrifuge can bring both real and intangible advantages and cost reductions, including:

1: Reduces the overall volume of waste by up to 70%

2: Produces a sludge-like stacking cake with no free liquid

3: Reduces sludge volume and weight, lowering handling expenses

4: Increases the number of sludge disposal alternatives

5: There will be less mess and accompanying clean-up

The following is an example of a common and simple process description-

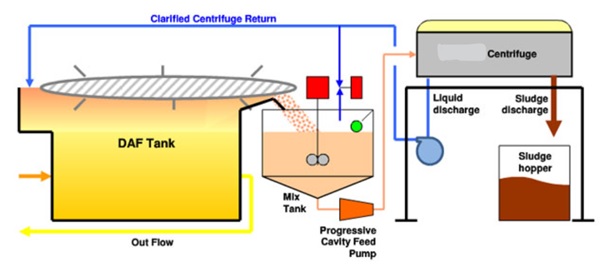

Process wastewater runs into the DAF tank, where suspended particles float to the surface, generating a layer or blanket of material that is scraped off and dumped into a wet sludge holding tank and/or mix tank on a regular or continuous basis.

A progressive cavity feed pump gently agitates the particles into a homogenous dilution of solids and liquid, which is then delivered to the centrifuge.

If necessary, an extra chemical additive may be added to aid in the separation and drying of the sludge cake. With "fatty" solids, this is more common.

The centrifuge is fed constantly by a progressive cavity feed pump that pulls from the bottom of the mix tank and is controlled by a VFD to optimize pump speed and flow rate. The cleared centrifuge concentrate is returned to the head of the DAF or collecting pit/tank by gravity and/or balance tank with centrifugal pump. The separated materials are continually discharged from the centrifuge into a sludge hopper beneath it.

To maintain process conditions, a float switch opens a usually closed butterfly valve in the cleared liquid discharge line and supplies re-circulated make-up water to the mix tank under low level situations.

(PROCESS DESCRIPTION IN PICTORIAL FORM)

The following factors influence the procedure's effectiveness

1: The origins of muck

2: The proportion of air to solids

3: The recycling rate

4: The thickness of the sludge blanket

Because primary sludge have a larger particle density, flotation is less successful in treating them than secondary sludge. They also include a significant amount of grit, which settles towards the bottom of the DAF unit. Scrapers, like gravity thickeners, are used to gather sediment in DAF thickeners.

Air to Solids Ratio

The quantity of air used per unit mass of sludge solids is known as the air to solids ratio. This ratio is generally in the range of 0.02006 kg air/kg DS for sludge thickening applications.

Because gas concentration rises with pressure, the pressure determines the concentration of air in the recycling stream. The recycle ratio, which is the ratio of the recycle flow rate to that of the influent sludge, determines the quantity of air available for flotation.

The speed of the surface sludge scrapers may influence the thickness of the floating sludge blanket, with blanket thickness decreasing as scraper speed increases. The sludge blanket needs to be thin enough to prevent particles from getting into the cleared effluent. Carry-over is generally limited to a maximum cleared effluent solids content of no more than 100 mg/L with a thickness of 150–200 mm.

Conclusion

Netsol is the globally leading water solutions company, providing all the related items. Netsol is a promising manufacturers of water treatment plants and also a service provider of the related plants.

If you are curious about the procedure of sludge thickening using DAF, you can talk to our experts and get your doubts settled.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.