How to recharge the resin of a Water softener?

The resin beads in a water softener get covered with hard minerals over time and must be cleaned.

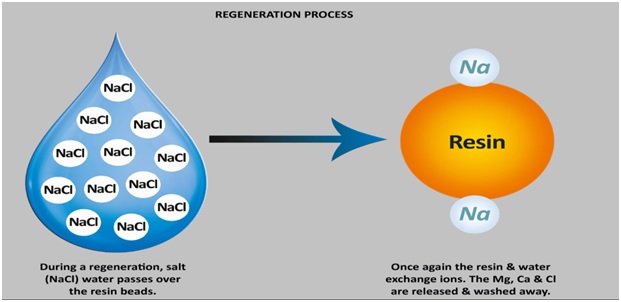

The regeneration process is essentially a resin cleaning cycle!

The resin will need to be flushed to recharge/clean once it has swapped as many magnesium and calcium ions as it can through ion-exchange. At this stage, the cylinder comes to a temporary halt in order to clean.A salt solution must be flushed through the resin to recharge it — (hence why you put salt in a water softener).

During the last phases of the regeneration cycle, the undesired magnesium, calcium, and chloride (Cl - salt) ions are flushed down the drain, and the resin is thoroughly cleaned. The cylinder is then reconnected.

The beads are reactivated by covering them with sodium ions, allowing the water softener to continue the process and remove more magnesium and calcium ions from the incoming hard water.

Recharging the resin_

If there has been a period of heavy usage, such as when there are extra occupants in the building or when you've been running extra loads of laundry, a manual regeneration of a water softener, causing it to back-wash and then re-charge the salt treatment of the resin in the treatment tank, may be necessary.

Fill, Brining, Brine Rinse, Backwash, and Fast Rinse are the five steps of recharging!

Note: The periods for each of these steps during recharging vary, and they alter almost every time the water softener regenerates, depending on how much water was used and what the system predicted for future water demands.

1: Fill

Brine is salt that has been dissolved in water. To remove the hard minerals from the resin beads, brine is required. During the fill stage, water flows into the salt storage compartment to produce the brine. This might take anything from a few minutes to up to 20 minutes.

2: Brining

Brine goes from the salt storage area to the resin tank during brining. The cleaning chemical used to remove stubborn minerals from resin beads is brine. The brine and hard minerals are flushed down the toilet. This might take anything from 30 minutes to up to 100 minutes. To obtain the finest resin cleaning with the least quantity of salt, the nozzle and venturi generate a suction to flow the brine at a very slow rate.

3: Brine Rinse

The brine valve closes once a certain amount of brine has been utilized. The water then flows in the same direction as during brining, but without the brine. Hard minerals and brine from the resin tank are flushed down the drain.

4: Backwash

Backwashing involves a rapid flow of water up through the resin tank. Any collected iron, filth, and sediments are flushed out of the resin bed and into the drain. The time it takes varies, but it usually takes 3 to 10 minutes.

5: Rinse quickly

A quick flow of water down through the resin tank follows the backwash. The quick flow removes brine from the tank's bottom. It also helps to keep the resin beads in place. After a quick cleaning, the water softener system resumes water softening function. The time it takes varies, but it usually takes 3 to 10 minutes.

What can we offer?

If you need help in designing or installing an efficient Water softener or if you feel the need to recharge the resin of a water softener, contact Netsol Water. We can help you with design calculations, budgetary expenses, preliminary layouts, and a lifetime cost analysis.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.