How to Control Scale and Hardness of Water?

Water quality management is required in the majority of industrial, business, and residential applications. Scale formation and water hardness are two of the most common issues faced, which lead to equipment corrosion, reduce efficiency, and increase maintenance costs. To solve these problems, two technologies have been widely applied, which are Reverse Osmosis (RO) and Ion-Exchange. Comparison of how both methods operate is critical in selecting the right solution.

We are going to cover scale and hardness control and compare the RO and ion-exchange processes in terms of operation, efficiency, cost, and application.

What Is Scale and Hardness?

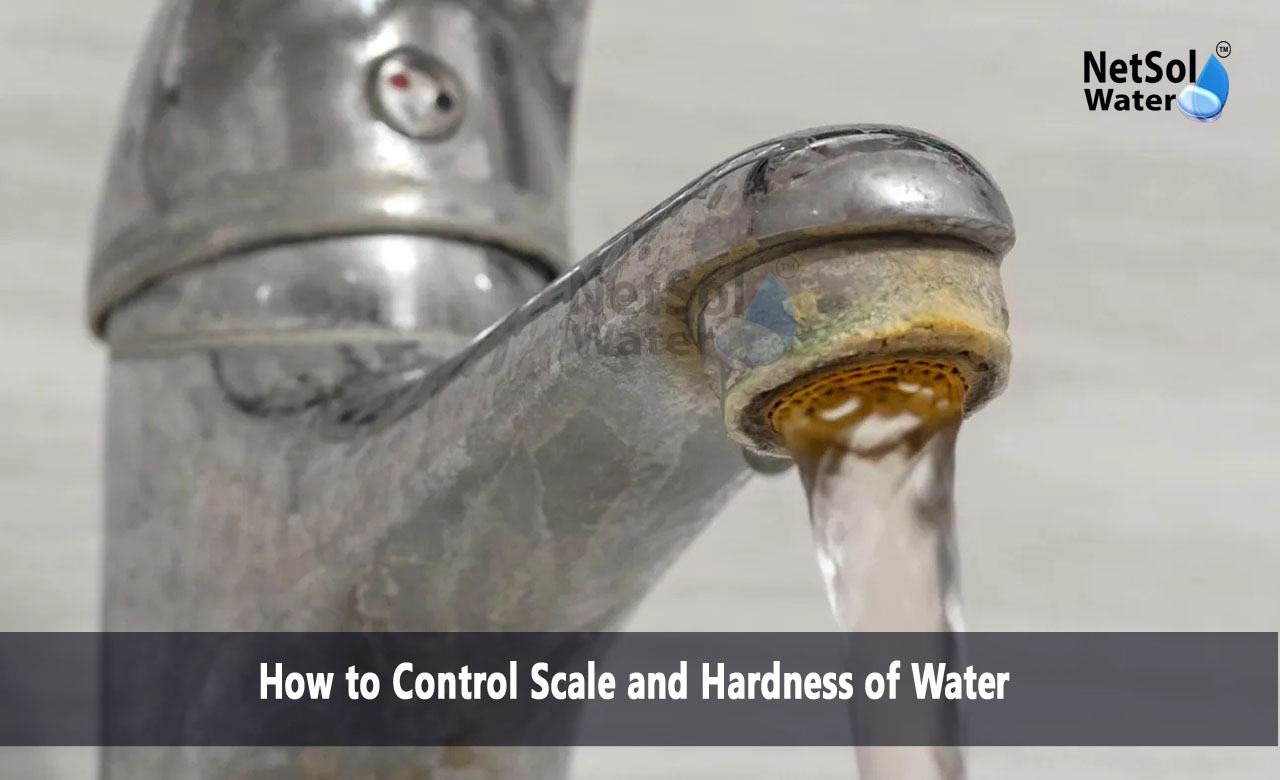

Scale is a whitish hard deposit formed as a result of precipitation of minerals such as calcium and magnesium in water to a surface. It will precipitate out in the size of pipes to form scales there, foul membranes, and lower the rate of heat transfer within boilers and cooling systems.

Hardness of water is condition of amount of calcium and magnesium in water. Scaling and soap interference which are caused by hard water can cause a negative impact on both domestic and industrial activities.

To protect the equipment and water quality, the scale and heating of the water should be controlled.

Reverse Osmosis Scale and Hardness Reduction

Reverse osmosis is a filtering process that utilizes compression on water to expel a full scope of dissolved solids in the water, alongside hardness-precipitating minerals. In RO plants, water is pushed through a semi-permeable membrane that rejects the ions and other impurities leaving pure, soft water on one side of the membrane.

Advantages of RO in Scale and Hardness Control

· Broad Spectrum Removal: RO not only removes calcium and magnesium but also salt, bacteria, and other impurities.

· Consistent Quality: Low total dissolved solids (TDS) treated water reduces scaling and corrosion risks.

· Water Reuse: RO allows high-quality water reuse in pure water-demanding applications.

Considerations

· RO plants produce a concentrate or reject stream of the removed minerals that should be properly disposed of.

· Scaling membrane fouling may be caused when pretreatment is poor, which requires more maintenance.

· RO plants require moderate levels of energy due to high-pressure pumps.

Ion-Exchange for Scaling and Hardness Control

Ion-exchange is a chemical process where hardness ions (mainly calcium and magnesium) are replaced by hydrogen or sodium ions using a resin bed. The resin captures and holds the hardness ions, thus softening the water flowing through it.

Advantages of Ion-Exchange in Scaling and Hardness Control

· Effective Softening: Ion-exchange directly tackles hardness ions and, as such, is highly effective in removing calcium and magnesium.

· Less Energy Consumption: Ion-exchange is low-pressure requiring, and therefore it is low-energy.

· Regenerable: The resin could be regenerated by salt solutions with repeated reuse over many cycles.

Points to Consider

· Ion-exchange does not reduce other dissolved impurities or solids.

· Brine waste is created on regeneration, which has to be got rid of.

· Soft water contains high sodium content, which may not be suitable in all applications.

Comparison of RO and Ion-Exchange: Important Points

|

Aspect |

Reverse Osmosis (RO) |

Ion-Exchange |

|

Effectiveness |

Removes wide range of dissolved solids including hardness ions |

Targets hardness ions specifically |

|

Water Quality |

Produces very low TDS water |

Produces softened water but TDS remains similar |

|

Energy Use |

Moderate due to high pressure pumping |

Low, no high pressure needed |

|

Waste Generation |

Reject water with concentrated salts |

Brine waste from resin regeneration |

|

Maintenance |

Membrane cleaning needed, fouling risks |

Resin replacement or regeneration required |

|

Cost |

Higher capital and operational cost |

Lower upfront cost, ongoing salt and resin costs |

|

Applications |

High purity water needs, boilers, pharmaceuticals |

Softening for domestic, commercial, and industrial use |

Choosing the Most Effective Method for Scale and Hardness Control

When choosing RO compared to ion-exchange for scale and hardness control, the following should be considered:

· Water Quality Requirements: For low TDS high-purity water applications, employ RO. For standard softening, ion-exchange will be sufficient.

· Volume and Flow Rate: Ion-exchange plants treat large flow rates economically, although RO can be used for smaller or more important streams.

· Waste Disposal: Consider methods of disposal of RO reject or ion-exchange brine securely.

· Energy and Operating Costs: Ion-exchange tends to be less energy-intensive, but RO can decrease chemical usage.

· Space and Maintenance: RO involves membrane maintenance; ion-exchange involves resin management.

Conclusion

Both ion-exchange and RO have good scale and hardness control solutions, but each is applicable only in terms of specific water treatment goals, water quality, and working conditions. RO provides comprehensive removal of dissolved solids and is best applicable where ultrapure water is needed. Ion-exchange provides effective softening at lower energy cost and is best applicable to general hardness removal.

Understanding these variations helps industries and plants decide on the most cost-efficient and effective means of protecting their equipment, saving water, and delivering operating reliability.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473 Or write us at enquiry@netsolwater.com