How many zones are present in the Sedimentation tank?

In a traditional treatment process, sedimentation is the third phase.

After coagulation and flocculation, it occurs. Sedimentation uses gravity to eliminate suspended materials by slowing the flow of water and allowing the material to settle. The settleable materials settle to the bottom of the sedimentation basin, lowering the filtering process' workload.

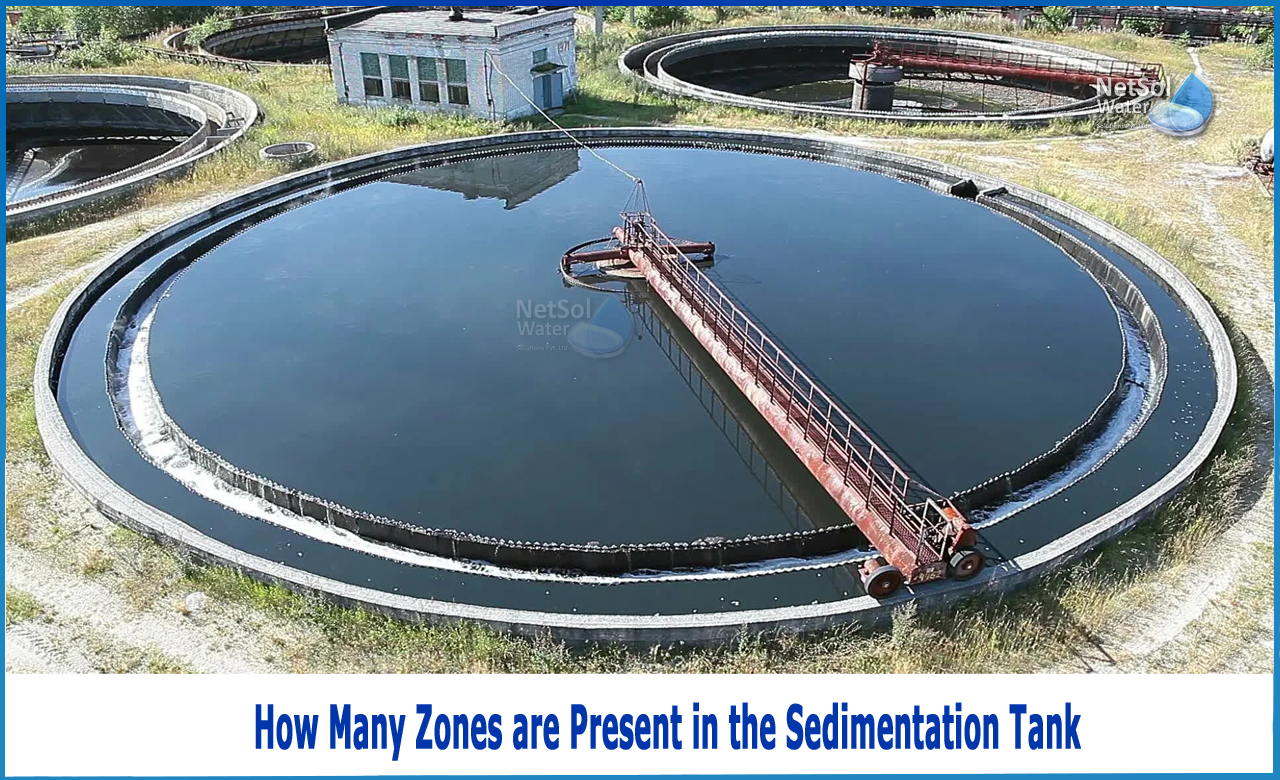

Sedimentation basin zones

The following zones are found in most sedimentation tanks:

1: Zone of the Inlet

The inlet or influent zone should evenly distribute flow throughout the tank's intake. Baffles are used in the standard design to gently disperse the flow throughout the tank's entire entrance and prevent short circuiting. (A condition in which portion of the influent water departs the tank too soon by flowing across the top or along the bottom is referred to as short circuiting.) Sometimes the baffle is constructed as a wall across the intake, with holes perforated across the tank's breadth.

2: Zone of Settlement

The sedimentation basin's settling zone is the greatest part. This zone offers the stillness that the suspended particles require to settle.

3: Zone of Sludge

The sludge zone, positioned at the tank's bottom, serves as a holding area for the sludge before it is taken for further treatment or disposal. Inlets in basins should be built to reduce high flow velocities towards the tank's bottom. Sludge could be swept up and out of the tank if high flow velocities are allowed to enter the sludge zone. Scraper or vacuum devices that move along the bottom, remove sludge from the sludge zone for further treatment.

4: Zone of Outlet

The basin exit zone (also known as the launder) should enable a seamless transition from the sedimentation zone to the tank's outlet.The depth of water in the basin is likewise controlled by this region of the tank. The overflow rate is controlled by weirs at the tank's end, which prevent sediments from rising to the weirs and exiting the tank before they settle out. The weir length in the tank must be sufficient to manage the overflow rate, which should not exceed 20,000 gallons per day per foot of weir.

Sedimentation Influencing Factors

The sedimentation process can be influenced by a variety of factors, including physical and environmental circumstances.

-When there are unfavourable conditions, more pretreatment may be required.

-Shape and size of particles, particle density, water temperature, and particle charge, dissolved compounds in the water, environmental influences, and basin characteristics are all factors that influence the sedimentation process.

-Smaller particles do not settle off easily, thus coagulation and flocculation are used to enhance their size. The larger, denser particles are referred to as floc. In the sedimentation process, particles larger than0.1 millimetres will sink. The form of the particles is also taken into account. Smoother, less jagged-edged particles settle out more quickly and easily.

-The settling rate will slow down as the temperature drops. When the water temperature drops, the settling rate or velocity drops. During the colder months of the year, chemical dose rates must be modified, or lower flows in the flocculation basins are required.

In a sedimentation basin, there are three types of currents: surface, density, and eddy.Wind causes surface currents, whereas temperature variations and solid concentrations create density currents. The influent and effluent water flows in the sedimentation basin create eddy currents. Currents can be useful since they aid in the formation of floc, but they can also create uneven solid dispersal over a sedimentation basin, lowering efficiency.

What do we offer?

If you are curious to know more about the sedimentation process and how to enhance the quality of water and wastewater, then you are at the right place!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.