Overview

Sludge management frequently accounts for 40% of the operational costs of a WWTP. Given the potentially dangerous nature of its content, a drop in conventional sludge treatment processes and a subsequent increase in external treatment charges are projected. In this instance, wastewater treatment plants will strive to produce as little sludge as feasible.

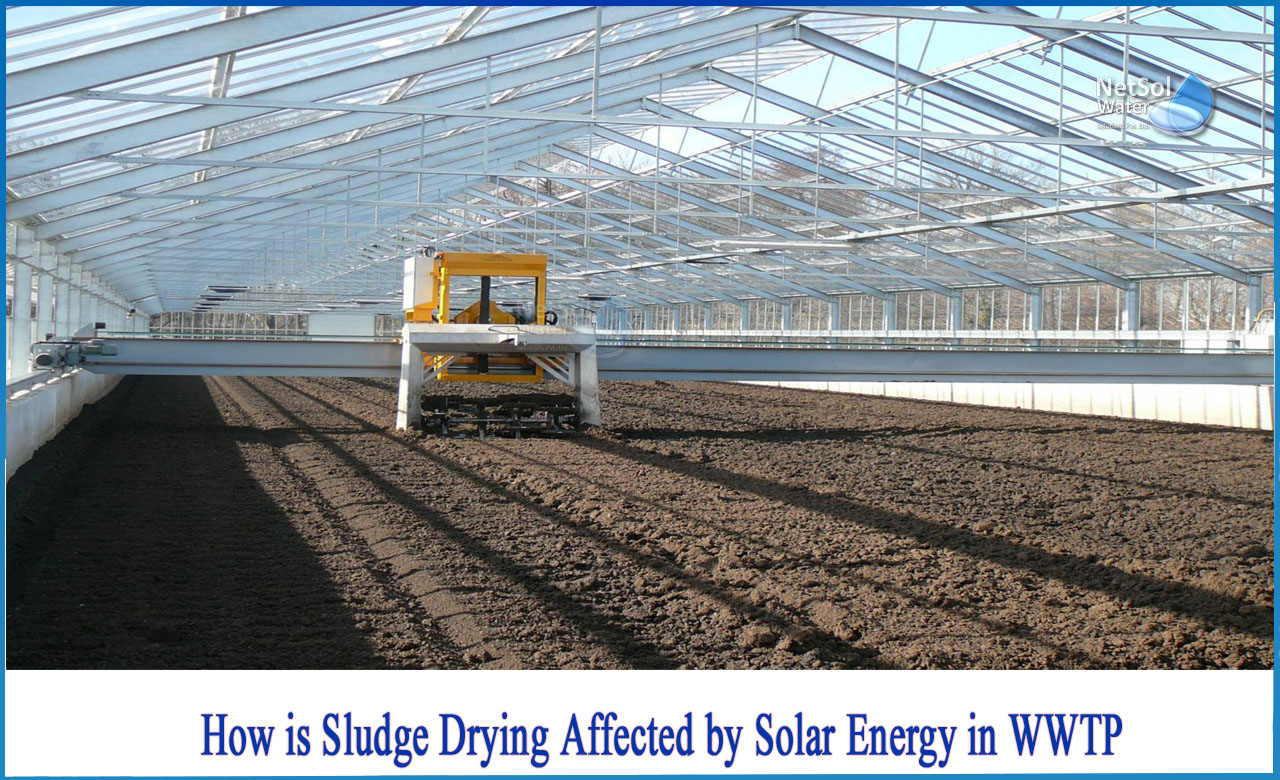

How is sludge drying affected by solar energy in WWTP?

Drying thickened sludge (15-30% dry matter) is a very environmentally friendly and low-energy solution. Suppliers of solar drying methods agree that after mechanical dewatering, the volume of sludge dry matter may be raised by 20% to 75–85%. (I.e. presses, separators). In terms of economics, it means four times reduced costs for export and external treatment at the disposal site, incineration facility, or elsewhere.

The approach is based on the homogeneous dispersion of sludge along the building's glass-lined walls and rooftops. Regular mixing is required for sludge to dry faster and to prevent odour in areas where the sludge may sensitize.

Such applications are designed for municipalities ranging in size from 2,500 P.E. (population equivalent) to 100,000 P.E. Naturally, built-up spaces must be commensurate in size, and they are often very large: from hundreds of square meters to 7,000 m2. A treatment of this magnitude generates between 1 and 10 thousand tons of sludge dry matter each year.

Maintaining the process's stability

The method can be assisted because this procedure is dependent on the season, weather, and quantity of solar days. Larger WWTPs process the sludge anaerobically, yielding energy-rich biogas.The biogas is then frequently used in boilers or cogeneration units that generate both heat and power. One portion of the produced heat is used to power the septic tank, another to power the buildings, and the remainder is squandered. This heat excess might be utilized to dry the thicker sludge further.

The use of these technologies and the aim to minimize sludge volumes are motivated by:

? Laws and regulations,

? The presence of potentially dangerous substances in the sludge,

? Hypothetical increase in price for sludge disposal.

What are the advantages, principle & application of solar sludge drying?

One benefit of solar sludge dryers is greater performance, or rather drying efficiency, and about ten times less built-up space required. Another advantage is that it has a comparable heating value to lignite and may be used in co-incineration.

Why should WWTP sludge be dried?

Dried or processed sludge has a wide range of uses, the most common of which is agricultural field application. When the drying process to make biosolids is done, the biosolids operate as a fertilizer for crop harvesting. Since these plant nutrients are provided progressively throughout the growing season, crops absorb the organic nitrogen and phosphorus included in biosolids quite well. The crop will be able to absorb these nutrients as it matures.

Aside from crop harvesting, processed sludge may be utilized as top dressing on golf course fairways, soil conditioner for park and athletic field building, a soil substitute in final landfill cover, and so on.

Due to their composition, several types of industrial wastewater and industrial sludge are currently classified as hazardous waste. As a result, reducing the amount of sludge is highly desirable. Sludge drying methods have the potential to drastically cut the operating costs of such plants.

Netsol Water is one of the best manufacturers of WWTP’s, ETP’s, STP’s, etc. across India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.