What is sludge?

Sludge is a semi-solid residual byproduct of industrial or refining processes. It's a separated solid suspended in a liquid, with a lot of water between the solid particles. Drying this material reduces its volume and the moisture content of the biosolids in the sludge.

The water content of sludge produced during waste water treatment ranges between 97 and 99.5 percent. Sludge thickening increases the dry and solid content of sludge by reducing the water content with a low energy input. This task is typically carried out in a tank known as a gravity thickener.

What is gravity thickening?

Gravity thickening is one of the simplest ways to reduce the water content of sludge while using little energy. The process has the potential to reduce the total volume of sludge to less than half of its original volume.

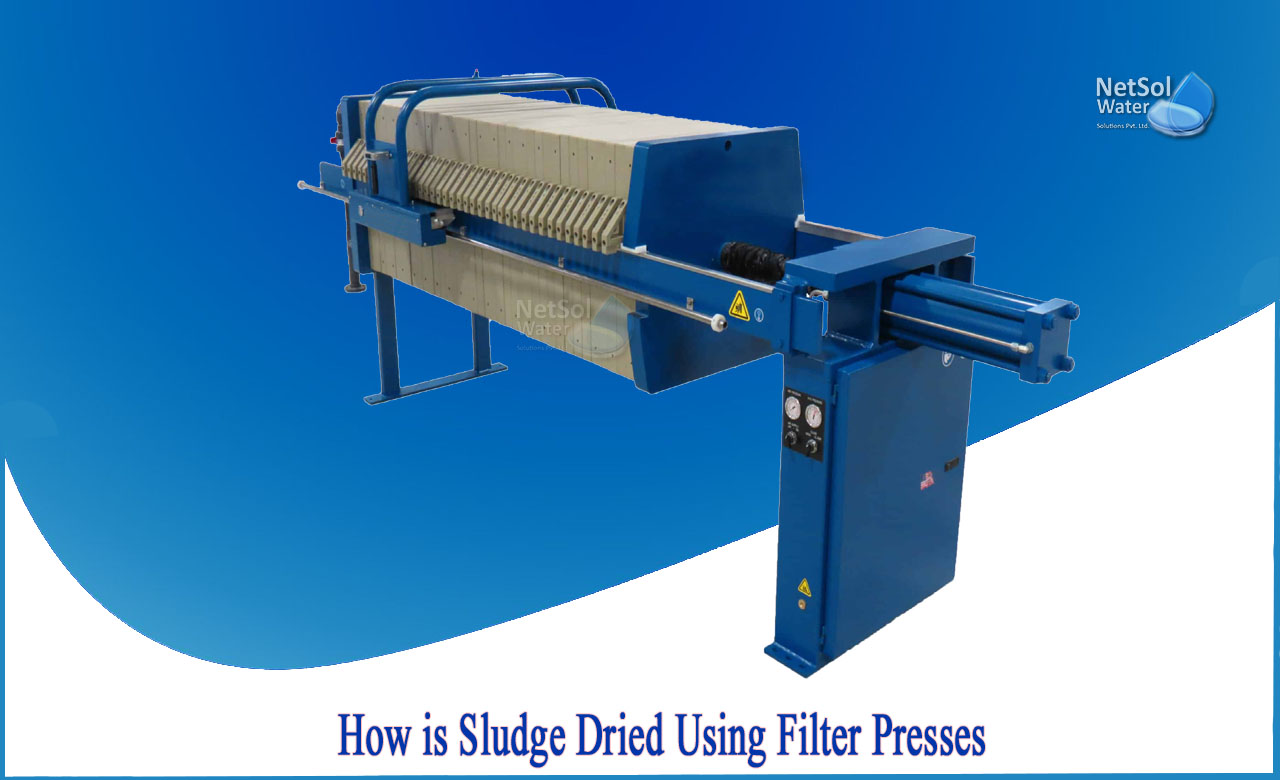

How is sludge dried using filter presses?

This is essentially a thermal drying process in which thermal energy is applied to the sludge in order for it to evaporate water. The drying process reduces the volume of the product, making it easier to store, transport, package, and sell.

There are two methods for drying sludge: direct and indirect. Indirect thermal drying, on the other hand, is gaining popularity as a method of reducing sludge volume by removing moisture and achieving a dry solids content of 90%. The process has low-impact on the environment and produces a stabilized dry granular product that is simple to store, deliver, and use in agriculture.

Applications of Sludge Drying

Dried or treated sludge has a wide range of applications, the most common of which is agricultural land application. When the drying process to produce biosolids is completed, the biosolids act as a fertilizer for crop harvesting. Crops efficiently use the organic nitrogen and phosphorous found in biosolids because these plant nutrients are released gradually throughout the growing season. These nutrients will be absorbed by the crop as it grows.

How do filter presses function?

Sludge is dewatered by pressing it between a series of porous plates in a filter press (FP). The process extracts water from sludge by applying high pressures to sludge layers held between a series of 2080 rectangular plates. The plates are recessed to allow for sludge filling, and each has a filter cloth with an effective pore size of less than 0.1 mm.

It is also the only dewatering technology capable of consistently achieving high concentrations of the dewatered solids cake product – between 35 and 45 percent DS (dry solids), depending on the origin of the feed sludge and the chemical conditioning used.

How does filter press work?

The filter press works by slowly filling the recesses between the plates with sludge before applying pressures of 720 bar over a 12-hour period. Under the applied pressures, water is forced out of the sludge, and the filtrate is returned to the wastewater treatment works influent.

The system is then flushed with air for 515 minutes to remove the majority of the residual water from the cake formed in the recesses. At this point, the filter cake can be washed to remove contaminants. After that, the plates are separated and the cake solids, which are 2540 mm thick, are allowed to fall out.

The diaphragm/membrane press is a variation on the standard FP. A flexible diaphragm is sandwiched between the filter cloth and the supporting plate in this technology. Dewatering is added by pressurizing the diaphragm (up to 20 bar) at the end of the pressing cycle to expand the diaphragm and apply additional pressure to the cake trapped in the recesses.

The filter press has also been modified to operate as a hybrid filter press/dryer, with the filter plates heated by a hot water system. Pilot trials using this technology under appropriate operating conditions have reported DS concentrations above 95%, with cake dryness increasing with increased operational cycle time, as with conventional FP.

These results are applicable to an un-thickened thermophilic anaerobically digested sludge starting material, implying that raw sludge dewatering and drying can be accomplished in a single stage.

For designing, installation of various STP’s, ETP’s, etc. contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.