Effluent is produced in a variety of industrial sectors, including textile, chemical, tannery, and pharmaceutical. Without treatment, polluted water cannot be released because it includes both toxic and non-toxic chemicals. Its release could contaminate currently clean water and have an impact on the ecosystem. ETPs are therefore implemented in the majority of manufacturing sectors.

The removal of large quantities of organic substances, debris, dirt, grit, pollution, toxic, non-toxic materials, and polymers, among other things, from industrial effluent is done using effluent treatment plants (ETPs). For chemical processing and effluent purification, the ETP facilities use evaporation and drying techniques in addition to other auxiliary methods like centrifuging, filtration, and incineration.

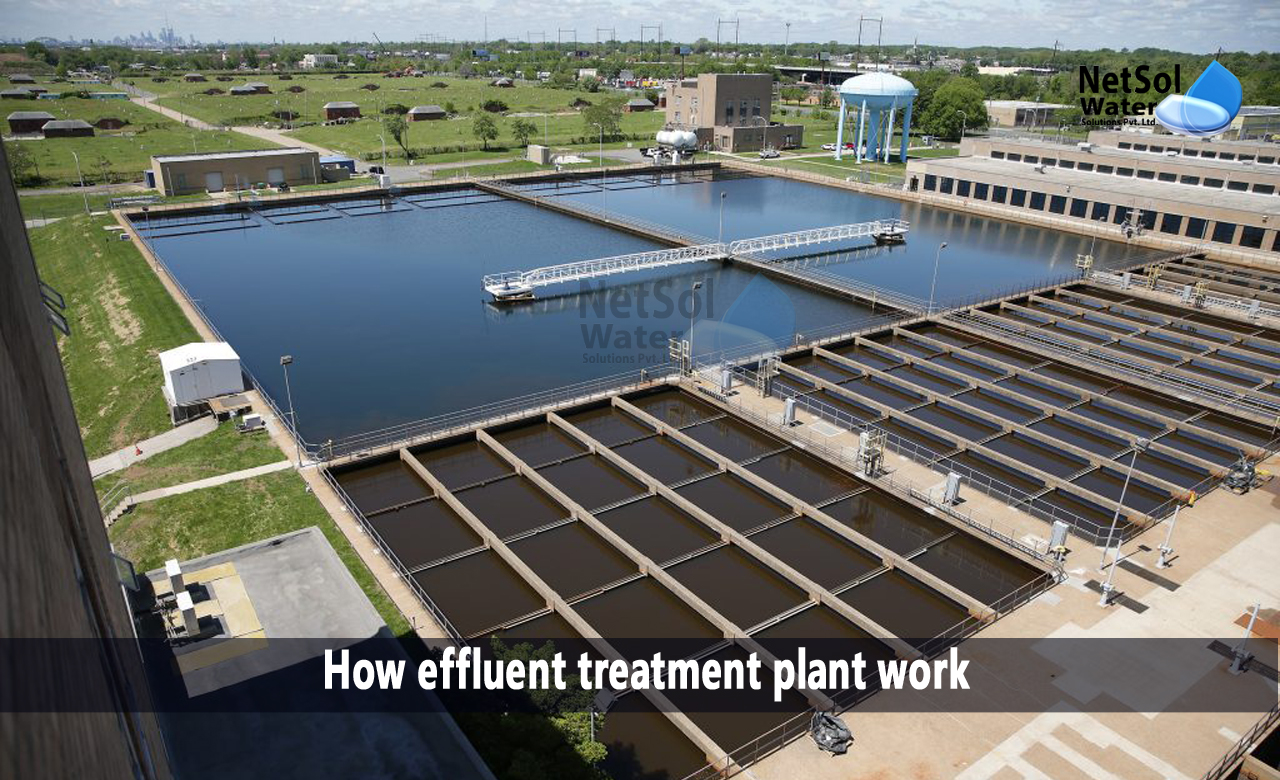

How effluent treatment plant work?

The conceptual approach of the treatment requires the elimination of suspended particles, the processing of dissolved organic matter, and the disposal of sludge. Various procedures that are involved are:

EQUALIZATION: The raw effluent generated by different processing plants is balanced in the equalization tank. The wastewater is gathered in an already-existing mixed effluent tank and sent to an already-existing aeration tank, which also serves as an equalization tank. The wastewater is homogenized using the floating aerator before being pumped to the neutralization tank for treatment.

pH CONTROL: The Bureau of Indian Standards specifies that the pH of effluent should range from 5.5 to 9.0. (BIS). Wastewater's pH is changed through pH neutralization.

For waste that is acidic (low pH): Bases are used to modify the pH of a solution. Acids are employed to alter a solution's pH in the case of alkali waste (high pH).

COAGULATION: Adding liquid aluminium sulphate to untreated water is a method known as coagulation. Due to the mixing that results, small dirt particles stick together. Through settling and filtration, it is simple to remove the bigger, heavier particles created by the combination of these smaller ones.

SEDIMENTATION: The water flows gradually in this process, resulting in the heavy particles settling to the bottom. The particles that collect at the bottom of a container are known as sludge.

FILTRATION: The process of filtering involves putting water through a device that traps particles. Sand and gravel layers are used to create the filters. These filters need to be cleaned frequently using backwashing.

DISINFECTION: Water is disinfected before it enters the distribution system. Water is cleaned and disinfected with chlorine.

SLUDGE DRYING: Solids are collected and brought to drying beds via sedimentation, which also causes them to settle. The sludge charging should be halted, and the bed separated so that natural evaporation can dry it out after the sludge thickness reaches about 300mm.

Design of ETP:

The design of the wastewater treatment plant is heavily influenced by the site and industry. Site and wastewater parameters are key factors considered when constructing effluent treatment plants. Standards for both treated and untreated effluent are taken into account while designing a wastewater treatment facility.

The process of choosing a treatment also entails taking into account a number of other variables, including treatment effectiveness, cost, and dependability.

Benefits of ETP:

ETP has the following advantages:

1. It cleans industrial effluent and recycles it for future use.

2. It decreases the need for fresh water in enterprises.

3. to protect the environment from pollution;

4. to adhere to the government's criteria for pollutant emission and avoid severe punishment

5. To cut back on water acquisition costs

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com