How Does the Oxidation Pond Process Work in STP Plants?

Sewage treatment plants play an important role in protecting public health and preserving the integrity of our water bodies. As communities grow and industrial activities expand, the volume and complexity of sewage generated continue to increase, presenting significant challenges for treatment facilities. Among the various treatment methods available, oxidation ponds have gained popularity for their simplicity, low operational costs, and ability to handle a wide range of sewage compositions. These man-made pond systems rely on the synergistic action of natural processes, including microbial degradation, aeration, and sunlight exposure, to effectively treat sewage and produce a high-quality effluent.

Understanding the Oxidation Pond Process

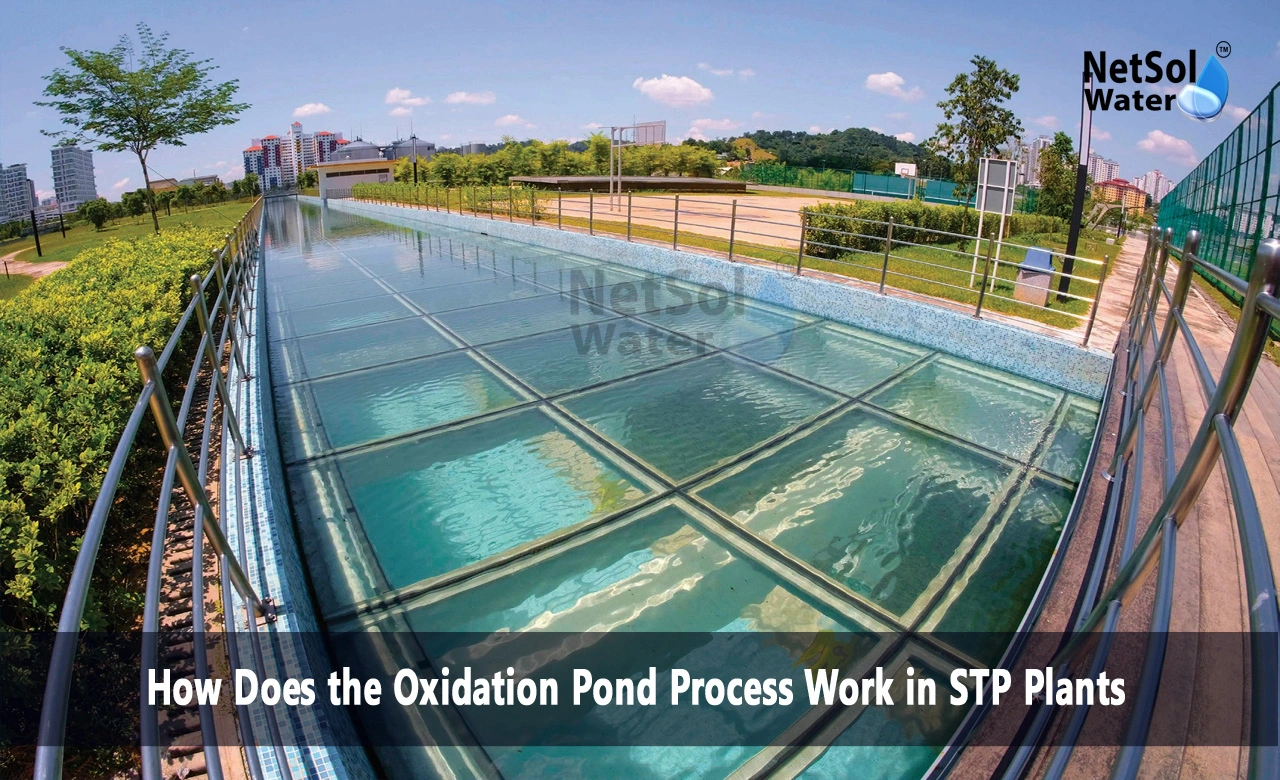

The Basics of Oxidation Ponds

Oxidation ponds, also known as stabilisation ponds or lagoons, are shallow, artificial basins designed to facilitate the biological treatment of sewage. These ponds typically consist of a series of interconnected cells or compartments, allowing for a multi-stage treatment process. The treatment process within an oxidation pond system is driven by two primary mechanisms: aerobic and anaerobic decomposition. These mechanisms work in tandem to break down and stabilise the organic matter, nutrients, and other contaminants present in the sewage.

Step 1: Anaerobic Decomposition

The first stage of the oxidation pond process involves anaerobic decomposition, which occurs in the absence of oxygen. As the sewage enters the initial pond or compartment, it settles, and anaerobic bacteria begin to break down the organic matter through a process known as fermentation. During this stage, the anaerobic bacteria convert the complex organic compounds into simpler substances, such as organic acids, alcohols, and gases like methane and carbon dioxide. This initial breakdown sets the stage for further treatment in the subsequent aerobic stages.

Step 2: Aerobic Decomposition

As the partially treated sewage flows into the next compartment or series of ponds, it encounters an aerobic environment. Here, oxygen is introduced through natural processes like wind-driven surface aeration, algal photosynthesis, and, in some cases, mechanical aeration devices. Aerobic bacteria, which thrive in the presence of oxygen, take over and continue the decomposition process. These microorganisms consume the organic matter and nutrients, converting them into carbon dioxide, water, and new bacterial cells (biomass).The aerobic stage is crucial for achieving a high level of treatment and reducing the organic load in the sewage. The combination of microbial activity and exposure to sunlight also helps eliminate pathogens and promote the breakdown of residual contaminants.

Step 3: Sedimentation and Polishing

After the aerobic decomposition stage, the treated sewage, now referred to as effluent, enters a final compartment or polishing pond. In this stage, the remaining solids and biomass are allowed to settle, further clarifying the effluent. The polishing pond also provides additional treatment through continued exposure to sunlight and microbial activity. This final stage ensures that the effluent meets the required quality standards before being discharged into receiving water bodies or reused for specific purposes, such as irrigation or industrial applications.

Benefits of Oxidation Pond Systems

Low Operational Costs

One of the primary advantages of oxidation ponds is their low operational costs. These systems rely heavily on natural processes, minimising the need for complex machinery, chemicals, and energy inputs. The reliance on sunlight, wind, and microbial activity significantly reduces the overall operational expenses compared to conventional treatment methods.

Effective Treatment

Despite their simplicity, oxidation ponds are highly effective in treating a wide range of sewage compositions. The multi-stage process, combining anaerobic and aerobic decomposition, ensures thorough breakdown and stabilisation of organic matter, nutrients, and other contaminants.

Environmental Sustainability

Oxidation ponds are considered an environmentally friendly sewage treatment solution. By harnessing natural processes and minimising the use of chemicals and energy-intensive equipment, these systems have a relatively low carbon footprint and minimal environmental impact.

Adaptability and Flexibility

Oxidation pond systems can be easily adapted to handle fluctuations in sewage flow rates and compositions. Their modular design allows for the addition or modification of pond compartments, ensuring flexibility in treatment capacity and process optimisation.

Applications of Oxidation Ponds

Municipal Sewage Treatment

Oxidation ponds are widely used in municipal sewage treatment facilities, particularly in small to medium-sized communities. Their cost-effectiveness and ease of operation make them an attractive option for areas with limited resources or where land availability is not a significant constraint.

Industrial Wastewater Treatment

Certain industries, such as food processing, agriculture, and aquaculture, can benefit from the use of oxidation ponds to treat their wastewater streams. These systems are effective in reducing the organic load and stabilising industrial effluents before discharge or reuse.

Decentralised Treatment Solutions

In remote or rural areas where centralised sewage treatment infrastructure is not feasible, oxidation ponds can serve as decentralised treatment solutions. They can be constructed on-site and tailored to the specific needs of the community or facility, providing a cost-effective and sustainable alternative.

Challenges and Considerations

While oxidation ponds offer numerous benefits, there are also challenges and considerations to keep in mind:

1. Land Requirements: Oxidation pond systems typically require a larger land area compared to other treatment methods, which may be a limitation in densely populated or land-constrained regions.

2. Odor Management: If not properly designed and maintained, oxidation ponds can potentially generate unpleasant odours, particularly during the anaerobic decomposition stage. Effective odour control measures, such as aeration and buffer zones, may be necessary.

3. Temperature Sensitivity: The efficiency of the microbial processes within oxidation ponds can be influenced by temperature fluctuations, which may affect treatment performance in colder climates or during extreme weather conditions.

4. Effluent Quality Limitations: While oxidation ponds are effective in removing organic matter and stabilising sewage, they may not achieve the same level of nutrient removal or pathogen inactivation as advanced treatment technologies. Additional treatment steps may be required to meet stringent effluent quality standards.

5.Sludge Management: Over time, sludge (accumulated solids and biomass) will accumulate in the oxidation ponds, requiring periodic removal and proper disposal to maintain system efficiency.

Conclusion

The oxidation pond process demonstrates the effectiveness of natural solutions in sewage treatment. By using the combined action of microorganisms, sunlight, and aeration, these man-made pond systems provide a cost-effective, sustainable, and efficient method for converting sewage into a safer and more environmentally friendly effluent. From municipal wastewater treatment facilities to industrial applications and decentralised solutions, oxidation ponds have proven their versatility and adaptability across a wide range of settings. Their low operational costs, effective treatment capabilities, and minimal environmental impact make them an attractive choice, particularly for communities and regions with limited resources.However, as with any treatment technology, careful consideration must be given to factors such as land availability, odour management, temperature sensitivity, effluent quality requirements, and sludge management. By addressing these challenges through proper system design, operation, and maintenance, oxidation ponds can continue to play an important role in sewage treatment plants.

To explore customised Commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com