How does quality of effluent affect an Effluent treatment plant?

It can be seen that the generation of industrial wastewater is overwhelming as a result of the rapid development of various industries, each of which produces its own unique combination of pollutants that severely pollute the surrounding environment. As a result, environmental regulations require all industrial units to install effluent treatment plants in order to reduce the direct discharge of untreated wastewater into bodies of water.

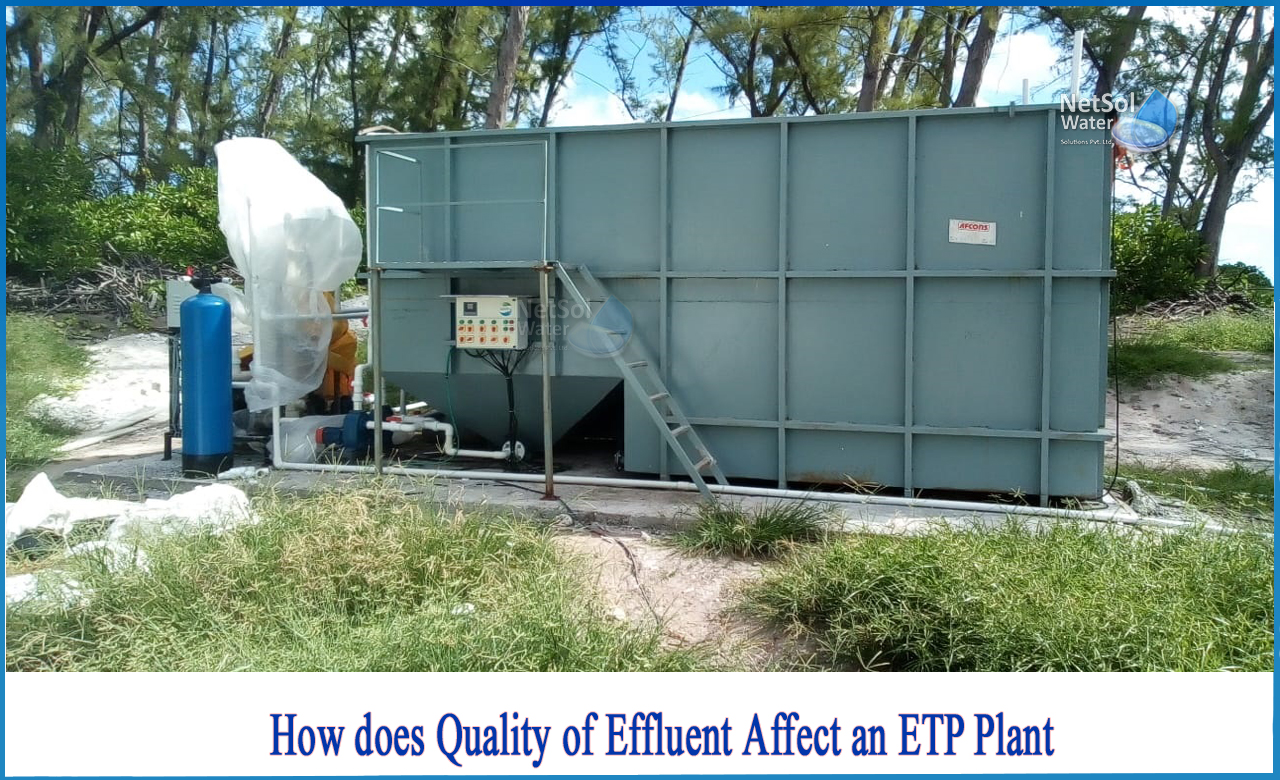

Municipal and industrial effluents, such as wastewater, sludge, or wastewater, are treated in effluent treatment plants. The manufacturers of these effluent treatment plants design the plant to remove harmful pathogens, hazardous chemicals, detergents, and toxins, as well as separate and extract valuable substances from the effluent.The recommended water treatment chemical is used to efficiently treat water in our country's numerous effluent treatment plants.

Application of effluent treatment plant:

The following major industries must install Effluent Treatment Plants (ETPs) to purify waste water before it is discharged:

· Food and Processing Industries

· Pharmaceutical Industry

· Textile and Paper Industries

· Automobile Industry

· Textile and Dye Industry

· Dairy and Beverage Industry

Factors to be considered for the effluent treatment plant design:

The effluent flow, as well as the biological, chemical, and physical properties that can affect effluent quality, are the effluent characteristics to consider when designing your treatment plant.

One can determine the size of your effluent treatment plant based on the estimated entrance to the plant, which is usually calculated in cubic metres per day almost everywhere in the world. To ensure that the hydraulic calculations are correct, individual must obtain accurate estimates of the variations in the input.

This is also required to help determine the correct size of the pipes and transport channels. It must also account for the expected increase in effluent influx in the near future in its design. Or, at the very least, the Plant should be built in stages.

While designing effluent treatment plant, one must also consider some physical characteristics of the effluent. These are the colour, solids, temperature, and smell of the effluent. The presence of solids in suspension indicates that the effluent is of poor quality and will be difficult to treat.

The size of the input could vary seasonally. For example, during the day, there may be more entries than at night. Again, during the rainy season, the inflow is likely to be greater. It should stabilise this flow and make it constant or nearly constant in order to protect the downstream treatment processes from damage.

This can be accomplished by using clearing tanks or ponds. Toxic substances in effluent can have an impact on the processes that treat the effluent. This effect can be mitigated by diluting the toxic effluent and mixing it in equalisation ponds with a less toxic effluent.

During festival seasons, such as Diwali, Christmas, New Year, Ramzan, and other vacations, the plant should withstand shock loads.

The Effluent treatment plant process is always dependent on how one design the ETP. The most important factor to consider is effluent quality, and if it is satisfactory, everything else will fall into place.

For more information, contact Netsol Water.