What is Reverse Osmosis?

Reverse osmosis (RO) is a continuous treatment process that employs pressure to flow source water through a thin membrane, separating contaminants from the water. Reverse osmosis reverses the osmosis principle, which is the natural tendency of water containing dissolved salts to flow across a membrane from a lower to a greater salt concentration.

Process of reverse osmosis

Pressure is utilized to overcome natural osmotic pressure in a RO system, driving feedwater with its load of dissolved salts and other impurities through a highly advanced, semi permeable membrane that eliminates a large proportion of the contaminants. This procedure produces highly purified water as a by-product.

Rejected salts and impurities concentrate and collect above the membrane before being drained or passed on to other processes. 75 percent of the feedwater is cleansed in a typical commercial or industrial application. 85 percent of the feedwater is purified in applications where water conservation is important.

The solution traverses the filter with two outputs in a RO system, with the filtered water going one way and the contaminated water going the other. Cross-flow filtration permits water to wash away pollutant accumulation while also providing enough turbulence to maintain the membrane's surface clean.

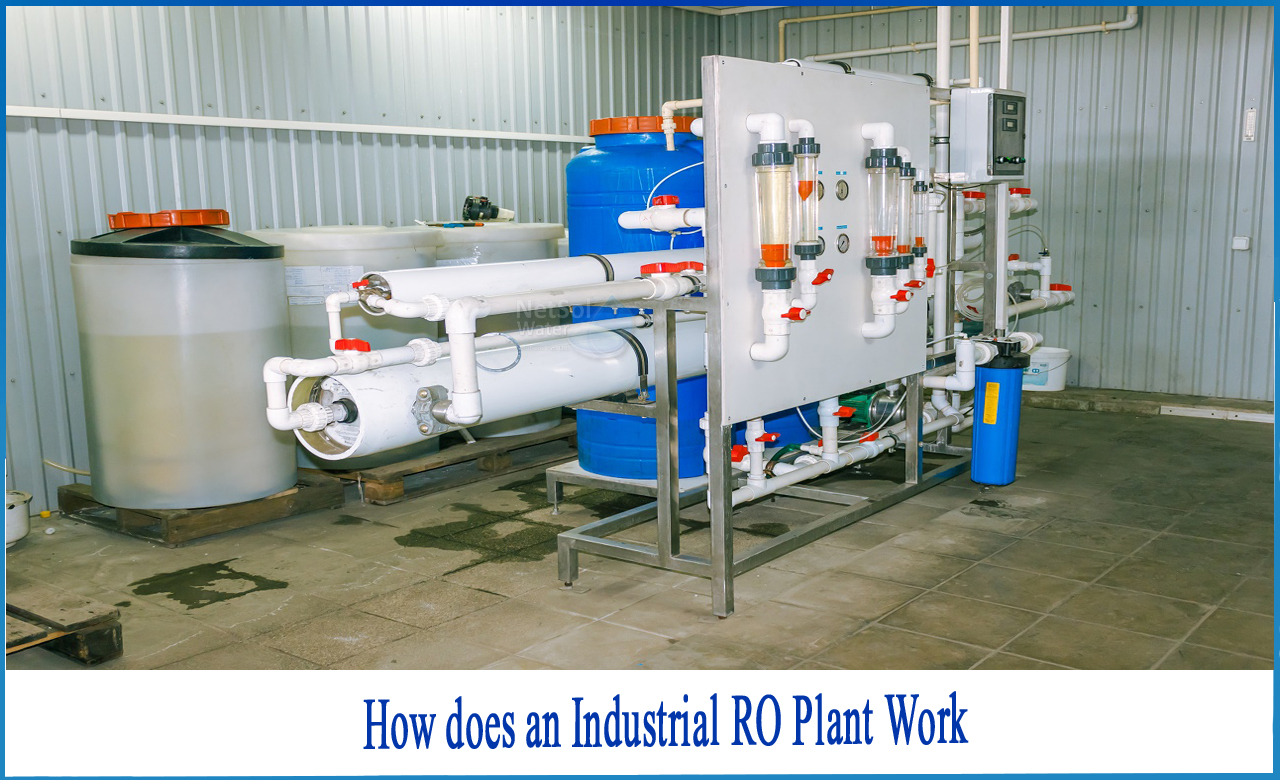

How does an Industrial RO Plant work?

When looking at a reverse osmosis schematic for an industrial plant, three to five primary steps may be visible.

A sediment filter, a carbon filter, and a semi-permeable membrane are all part of a three-stage reverse osmosis system. These are the first, second, and third phases, respectively.

Another membrane is added to a four-stage system to filter out particles that the previous membranes may have missed.

The same sediment filter, carbon filter, and semi-permeable membranes are used in a five-stage system. It also includes post-filtration, which involves passing the water through a carbon filter to remove any remaining contaminants. A remineralisation phase is included in certain five-stage RO systems, which restores useful minerals to the processed water.

1.Pre-filtration: There are two types of pre-filters in reverse osmosis systems that filter out bigger particles like silt and chlorine. The water passes through a sediment pre-filter, which filters out particles such as dust, silt, and rust. The water next passes through an activated carbon pre-filter, which binds to and eliminates contaminants such as chlorine and volatile organic compounds (VOCs).

2. Reverse osmosis: After pre-filtration, reverse osmosis is the primary event. The water is then passed across a semi-permeable membrane, which retains tiny, more difficult-to-remove dissolved solid particles. Reverse osmosis may frequently remove the vast majority of dissolved solids from water at this stage.

3. Drainage: After the water has passed through the semi-permeable membrane, the contaminants are removed and flushed down the drain. Contaminants that build up on the membrane can reduce its efficacy, therefore this step is critical. The RO system's efficiency is maintained by draining the accumulated contaminants.

4. Storage: The treated water is then stored until it is needed. A pressure tank big enough to hold the treated water without requiring waste is frequently used as the storage container. The cleaned water may additionally pass through a charcoal filter to eliminate any remaining contaminants.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated RO problems by strategically integrating modern treatment technology with practical solutions.

If you need any technical help, or simply have a query regarding our water and wastewater treatment technology solutions, contact one of our expert advisers via phone at +919650608473 or contact via email at enquiry@netsolwater.com