Zero liquid discharge plants are worthwhile to pursue if a facility is situated on a site, with severe water scarcity problems or exorbitant discharge fees, but if it's not required, careful consideration must be given to whether or not it will benefit your facility.

If zero liquid discharge treatment plant is a requirement at your facility, or is something you're thinking about, you might be curious about how it operates and how do these treat wastewater!

How do Zero liquid discharge (ZLD) plants treat wastewater?

Although, specific procedures for treatment vary, a common ZLD treatment center procedure often entails the following steps:

· Pretreatment and conditioning

Pretreatment is used to condition the water and reduce suspended solids and materials, which may otherwise scale or foul subsequent treatment procedures. It removes simple substances from the wastewater stream that can be filtered out or precipitated out.

Usually, the clarifier or reactor in this treatment block precipitates out the metals, hardness, and silica. To facilitate the coagulation process, which involves adding various chemicals to a reaction tank, to eliminate the bulk suspended particles and other pollutants, this stage occasionally calls for the use of caustic soda or lime.

This procedure begins with a variety of mixing reactors, usually one or two reactors that add chemicals to remove all of the smaller water particles, by combining them into larger particles that settle out.

Sometimes coagulating the particles will also benefit from a modest pH change!

· Flocculation

When coagulation is finished, the water enters a flocculation chamber where long-chain polymers, (charged molecules that grab all the colloidal and coagulated particles and pull them together), are slowly stirred in to combine the coagulated particles, resulting in visible, settleable particles that resemble snowflakes.

Flocculated material and water enter the chamber of the gravity settler, which is often a sizable ring-shaped machine, and circulate outward from the center. The sediments slowly settle to the bottom of the clarifier and form a sludge blanket, because of the water rising to the top and overflowing at the clarifier's edge.

The sludge is then pushed out of the bottom of the clarifier into a sludge-handling or dewatering operation, after the solids are slowly mixed in the center of the clarifier in a cylindrical tube.

This procedure produces a liquid that is then filter-pressed into a solid, leaving behind a solution with far fewer suspended particulates and no scaling-up treatment options.

· Phase-one concentration

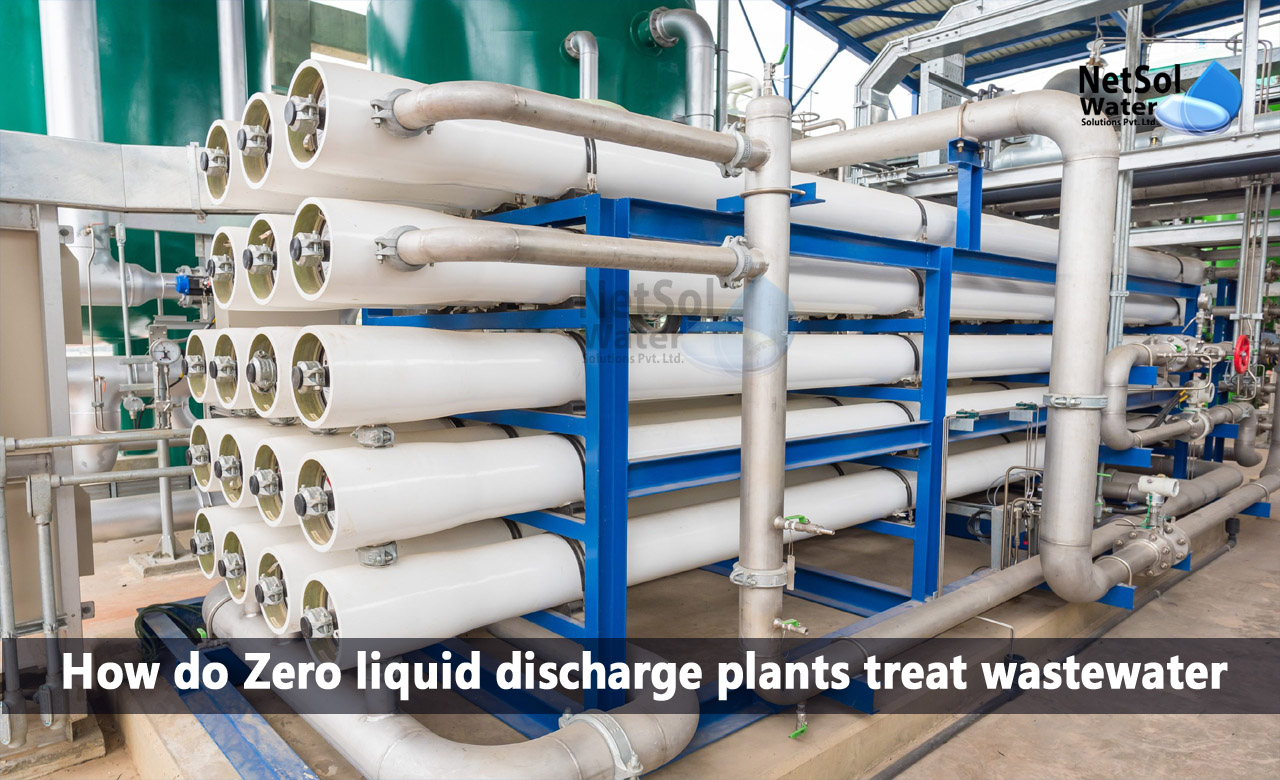

Reverse osmosis (RO), brine concentrators, or electrodialysis membranes, are frequently used for concentration in the early phases of ZLD.

RO Plant: Most of the dissolved solids that pass through the process will be captured by the RO train, but it's critical to only flow pre-treated water through the RO system, because untreated water will quickly foul semipermeable membranes.

Brine concentrators: On the other hand, brine concentrators can often handle brine with a significantly higher salt content than RO, and are also used to remove dissolved solid waste. They produce a reduced volume of waste fairly well.

Electrodialysis: This section of the ZLD treatment system also allows for the use of electrodialysis. It is a membrane method that may be applied in phases, to concentrate the brine and uses positively or negatively charged ions to allow charged particles, to pass through a semipermeable membrane.

It frequently works in tandem with RO to get incredibly high recovery rates. Together, these methods can concentrate this stream's salinity down to a high level, while removing between 60 and 80 percent of the water.

· Evaporation/crystallization

The process of creating a solid, which comes after concentration, is carried out through heat processes or evaporation, in which all the water is removed, collected, and used again. By adding acid now, you can neutralize the solution and prevent scaling and damage, to the heat exchangers when heating it.

To liberate dissolved oxygen, carbon dioxide, and other non-condensable gases during this stage, deaeration is frequently utilized.

The remaining waste is then transferred from an evaporator to a crystallizer, where it is heated until all the water has been removed and all the contaminants have crystallized, filtering out as a solid.

For further information or to make a purchase for RO Plants, ZLD Plants, or any other water and wastewater treatment products, contact us at +91-9650608473 or enquiry@netsolwater.com