While, reverse osmosis (RO) for treating wastewater is a very effective and cost-effective process, it is important to understand the water chemistry involved, as well as techniques for fouling control and system maintenance, because of its sensitivity to fouling.

Reverse osmosis or RO water must be produced by applying pressure, in order to force it through the membrane. This pressure ranges from 8 to 14 bars for fresh and brackish water and 40 to 70 bars for seawater.

But, do you know about how impurities get in the RO plant? If not, continue reading the blog for detailed information.

What is reverse osmosis plant or RO Plant?

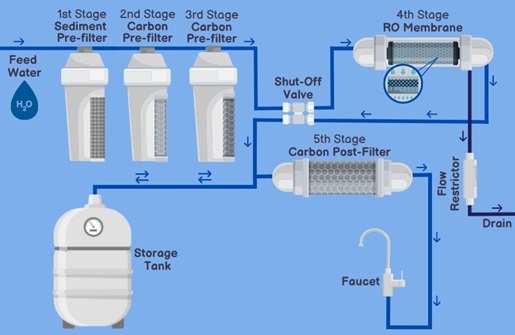

Reverse osmosis systems or RO Plant uses a semi-permeable membrane to reverse the flow of water, removing germs and TDS from dirty water to produce pure, clean water. Also, the reverse osmosis membrane is widely used in conjunction with pre and post-filters.

What does RO Plant remove?

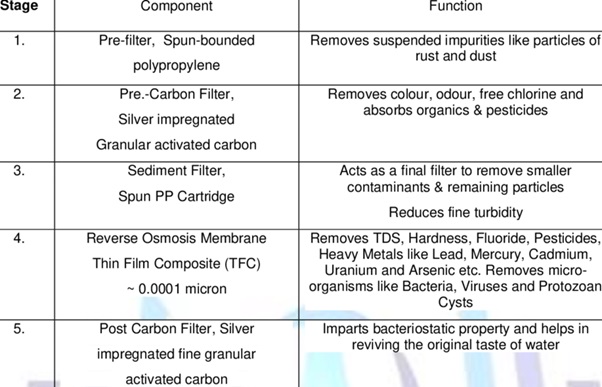

A reverse osmosis filter has pores that are around 0.0001 microns in size. Protozoa (like Cryptosporidium and Giardia) can be eliminated by RO systems very effectively, as can bacteria (like Campylobacter, Salmonella, Shigella, and E. coli), viruses (like Hepatitis A, Enteric, Norovirus, and Rotavirus), etc., as well as removing common chemical pollutants like TDS, metal ions, aqueous salts such as sodium, copper, chloride, and lead, as well as reducing arsenic, radium, fluoride, sulphate, magnesium, nitrate, calcium, etc.

With extensive expertise in the field of water treatment, Netsol Water has created complete, commercially feasible RO systems that minimise the capital outlay. We also offer our solutions in packaged water treatment plants, so that they can be upgraded later on when demand rises.

How do impurities get trapped in the RO Plant?

One or all of the following processes make up the RO plant, through which impurities are trapped at different stages.

1: Pretreatment in RO Plants

The pretreatment process for RO Plants may include the following treatment steps, depending on the quality of the raw water:

· Sand filtration

· Clarification

· Chlorine water purification

· Water softening reducing the hardness

· Scale inhibitors

· Using sodium bisulfite and activated carbon filters to reduce free chlorine

· Utilising cartridge filters to remove suspended particles completely

2: Dosing system for chlorine and hypochlorite

Before filtration, raw water is treated with a chlorine/hypo-chlorite dosing system to disinfect, and oxidise iron and manganese (if present). Sodium hypochlorite reacts to produce hypochlorite acids, in the presence of water.

3: Pressure sand filter

Before feeding the RO Plant, raw water is first filtered by filtration units connected in series. Suspended matter and turbidity from raw water are removed using a pressure sand filter machine.

4: Activated Carbon Filter

Basic natural water may contain varying amounts of color, odour, chlorine, and organics, all of which should be eliminated before using the water for drinking purposes. Chlorine, odour and color, pesticides, organics, and inorganic impurities are all removed, by the activated carbon filter as water passes over a carbon bed.

5: SMBS dosing system

The membrane may become oxidised by the chlorinated water, thus we provide a sodium metabisulphite dosing device to prevent this.

6: Anti-scalant dosing system

If the quantity of the calcium and magnesium hardness salts exceeds their solubility limit, they are likely to precipitate and may damage the membranes, causing scaling, which eventually results in poor treated water quality from a RO system. Antiscalant dosage (scale inhibitor) dosing system is offered to stop this.

7: Micron cartridge filter

A series of cartridge filters, including 20 micron, 10 micron, 5 micron, 1 micron, 0.45 micron, and 0.2 micron cartridges, are available. After a certain number of days of use, you should replace this consumable cartridge.

8: High-pressure pump

In order for the reverse osmosis process to work, the water feed pressure must be increased. A vertical multi-stage centrifugal high pressure pump is constructed with stainless steel, and is used in R.O Plant.

Operating pressure for the system must be between 14 and 16 kg/cm2. The high-pressure pump is equipped with stainless steel discharge piping, and the required control valves. For safer RO Plant operation, tools like a Pressure Gauge, High Pressure Switch, and recirculation valves are supplied.

9: RO System

The reverse osmosis system rejects between 97 and 99% of the total dissolved solids. R.O. Module assembly mounted atop a structural skid makes up this system. The skid that contains the spirally wound membrane elements in sequence, is supplied with high pressure rating FRP Pressure Vessels (Pressure Tubes).

Softened water from the input is split into two streams in the RO system:

1: Product water, and

2: Reject water.

Product water is purified water with a lower TDS level. Reject water is extremely concentrated water that should not be used for anything, other than draining. Followed, filtered water is first fed into a pressure vessel under high pressure, and then it is collected in the centre core tube.

The following instruments are available on the panel to ensure the safe operation of the system:

· Feed & Reject Pressure Gauge: To display the appropriate R.O. System pressure.

· Feed & Reject Flow Indicator: To display the corresponding R.O. System flow.

· TDS meter: Measure TDS in raw and treated water.

· High pressure switch: For tripping HPP in the event of excessive feed pressure.

· Time Totalizer: For tracking the number of hours an HP pump or RO system has been running.

10: Storage tank for product water

In a storage tank made of stainless steel with the necessary capacity, treated water from the RO Plant is collected. The tank is equipped with stainless steel pipes, isolation valves, and the appropriate kind of level indicator.

11: Removing the micro-biological growth with absolute micron cartridge filters

In treated water during storage, contamination from the atmosphere or any other source is possible. Therefore, water is once again passed through a micron cartridge filter, after being passed through a reverse osmosis system.

12: UV water purification

After additional treatments, cleaned water is devoid of all micro-biological pollutants like bacteria, viruses, etc., albeit they may reappear in the water during extended storage. Therefore, treating treated water with a UV water purification system is necessary.

The water that needs to be disinfected is run through an ultraviolet system, which comprises of UV tubes that emit intense ultraviolet rays that destroy microorganisms. This system comprises of an ultraviolet lamp-filled surface housing with a S.S. finish. During treatment, the water to be treated is in close proximity to these tubes. A system of electricity is offered to produce high voltage.

Netsol Water provides many different types of reverse osmosis plants (RO plants):

· Industrial RO Plants

In order to meet the demanding process requirements, we manufacture a broad range of industrial reverse osmosis plants. Our industrial reverse osmosis plants are expertly designed and set up, to meet each customer's specific needs for output water, which are related to industry-specific uses including food processing, medicines, and boiler feed requirements.

· Commercial RO Plants

The Commercial RO series, which is among our most popular, often comes in conventional Models. These commercial RO systems can be modified to include UV water purification systems, water softeners, antiscalant dosing systems, multimedia filters, and activated carbon filters.

· Containerized RO Plants

A variety of water treatment services are offered by Netsol Water Solutions in containerized form. These systems are inexpensive and plug-and-play and almost up-to 1000 m3/day of drinking water can be produced, by our containerized RO systems that are ready for use.

Get in touch with us to get high-quality water treatment services!

Contaminated water is harmful to the environment and to people's health. To prevent water pollution and to provide safe and clean drinking water to people, poisonous and dangerous substances that are released into the water must be eliminated.

In this regards, Netsol Water provides various water treatment solutions for any sector with high-quality, dependable products and a knowledgeable engineering group. Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.