Wastewater Treatment Using Ecological Methods:

Approximately two dozen ecological wastewater treatment plants have been built since the late 1980s, ranging from small systems serving individual schools to medium-sized municipal systems serving several thousand households to waste treatment plants for industries designed to treat specialized waste-water flows.

Sewage can be treated close to where it is generated, which is known as a "decentralized" or "on-site" system (in septic tanks, bio filters or aerobic treatment systems).Using the natural cycles of plant and animal life to process wastewater rather than chemicals and mechanical systems has a lot of appeal. Traditional sewage treatment systems already rely on bacteria to do a large portion of the work, but these organisms perform very specific functions within a mechanistic system. Ecological engineering incorporates more evolved flora and fauna into the equation, resulting in an appealing and informative wastewater treatment option.

What is ecological wastewater treatment?

To break down biological and chemical wastes, all sewage treatment plants rely on living organisms. Following that, various chemicals are used to precipitate sludge and disinfect the effluent.

Ecological wastewater treatment plants work in fundamentally similar ways, but they use highly diverse ecosystems with a diverse range of organisms—algae, aquatic plants, marsh plants, worms, crustaceans, mollusks, and vertebrates—that support populations of bacteria that break down wastes and eliminate nutrients from the wastewater.

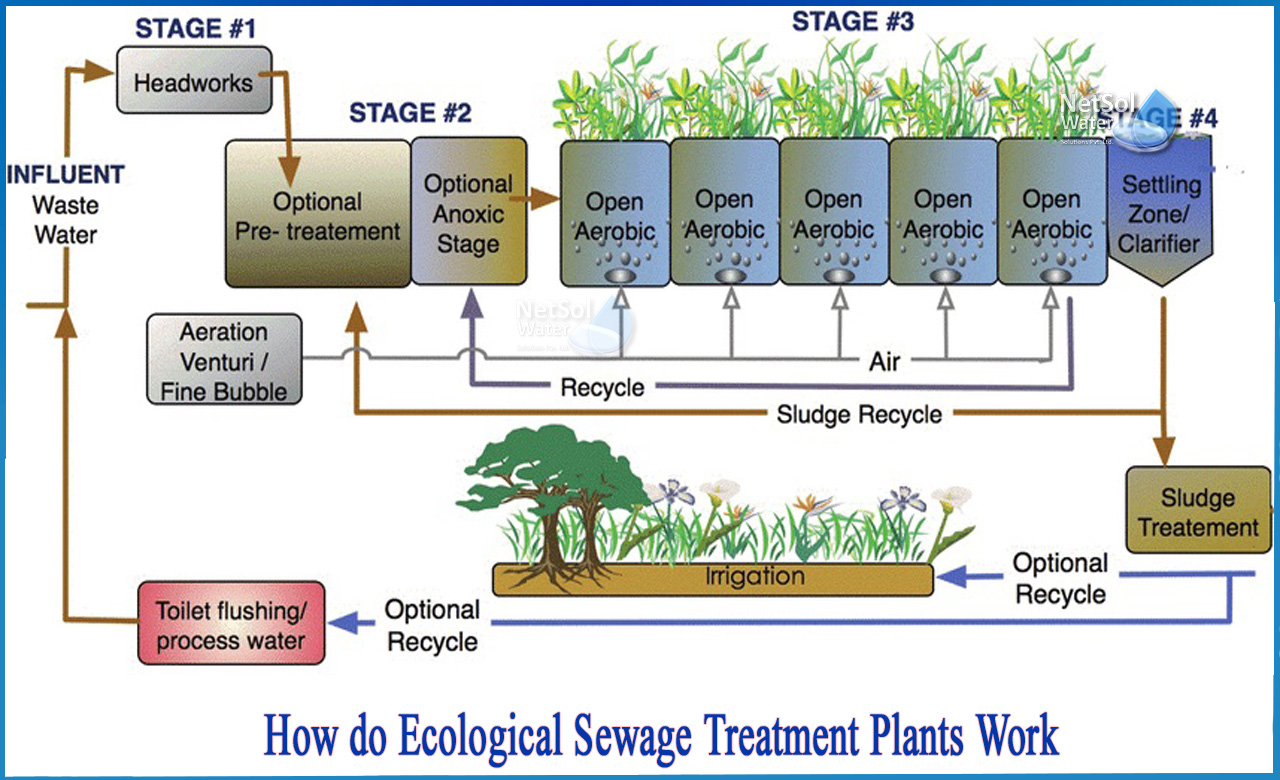

Though the specifics of each system vary greatly, the diagram below depicts a typical example of how an ecological wastewater treatment plant operates.

Working of an ecological wastewater treatment plant:

Raw sewage enters the system via an equalization tank, where grit is settled and bacteria are "seeded" to initiate biological activity. This stage can be a component of the ecological system or a component of a larger, conventional plant that provides sewage to the ecological system.

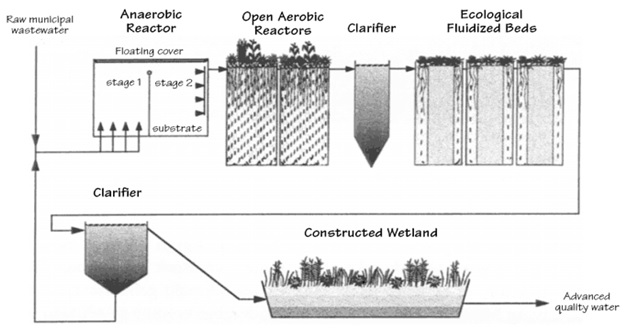

Anaerobic reactors may or may not be used for preliminary processing, depending on the strength of the wastewater. The wastewater is then routed through a series of aerated reactor tanks. These tanks are linked in series, with wastewater flowing from one to the next via gravity pressure.

In most cases, several parallel trains of these in-series tanks are used to increase retention time and provide redundancy in the event of a malfunction. Each tank contains a mini-ecosystem with a layer of floating aquatic plants on top (often supported by mesh netting). These plants' extensive root systems extend deep into the water, providing habitat for bacteria, which do the majority of the actual work in waste breakdown. Algae, small crustaceans, snails, and larger animals are also housed in the tanks.

After passing through this series of tanks, the water flows into a clarifier tank, where solids settle out as sludge. Some of these solids are removed and used to seed incoming sewage with bacteria; the remainder is removed for storage, composting, or land application.

The clarified water flows into a subsurface-flow constructed wetland in EEA plants (passing through a sand filter first in some facilities). The wetland preserves an anoxic environment in which anaerobic bacteria remove nitrogen from the water.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.