How are flows measured in Water and Wastewater Treatment Systems?

The quantification of water movement in a specific channel is known as flow measurement. The displacement and/or velocity of the water can be used to determine flow. Flow can be classified into two types: open channel flow and closed conduit flow. It is controlled by a series of valves placed at regular intervals to slow, allow faster flow, or entirely stop the flow. Some water meters combine the functions of taking readings and managing flow, while others focus solely on measurement.

Importance of measuring Flow

When it comes to knowing how to increase the efficiency of industrial operations, measuring water flow is critical. Precise measurements are also vital for conserving clean water that can be used in daily living.

Water and wastewater treatment facilities are responsible for ensuring that a safe supply of high-quality water is available. Their processes are “pump intensive,” with huge motors that consume a lot of energy. The importance of dependability cannot be overstated. Water and wastewater operations necessitate a wide range of flow measurement jobs, which necessitate the greatest meter accuracy and reliability, as well as long-term stability and low ownership costs. Flow meters must be able to detect liquid in all stages, including enormous volumes of fluid containing suspended particulates, sludge byproducts, and other substances.

They’re also utilized to keep track of methane emissions and reuse. The following are examples of typical flow measurement applications:

1: Monitoring of water flow;

2: Water treatment chemical dosing;

3: Monitoring of water use;

4: Detection and decrease of leaks;

5: Monitoring of the network load;

6: Water consumption optimization;

7: Quantity of influent water being monitored;

8: Quantity of discharged water being monitored;

9: Water flow between reservoirs being monitored.

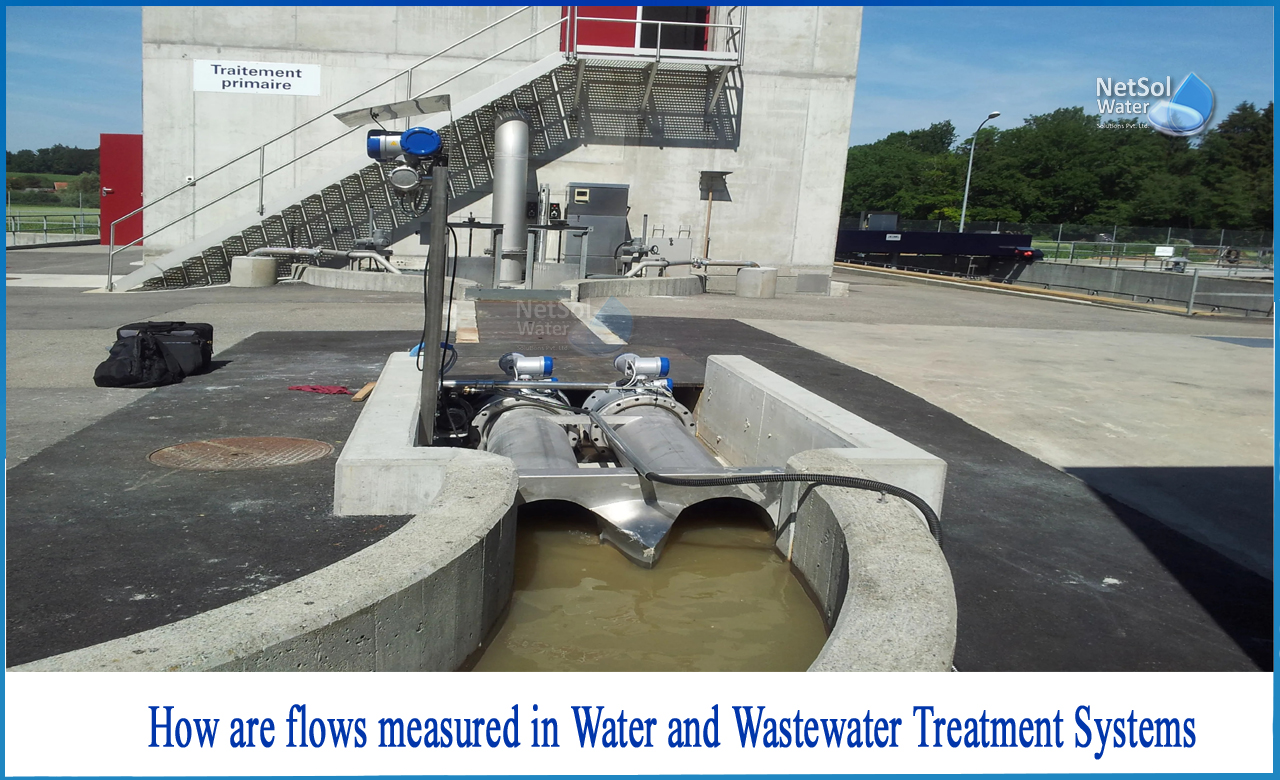

Flow measurement in water and wastewater treatment systems

Flow can be assessed in two ways: instantaneously and continuously.

A primary flow device, a secondary flow sensor, a transmitter, a flow recorder, and a totalizer are all part of a typical continuous system. The primary flow device can be used to get instantaneous flow measurements.

Although there are a number of flumes and weirs, as well as Venturimetres for closed flow circumstances, the Parshall flume v-notch weir is the most common primary flow device found. The hydraulic responses of the primary flow measurement equipment are measured by a secondary device, such as a flow sensor, and transmitted to the recording system. Ultrasonic transmitters, floats, pressure transducers, capacitance probes, differential pressure cells, electromagnetic cells, and other sensors are common.

Area velocity flow meters: The cross section and type of the channel in which the flowmeter is measuring depth and velocity are used to compute the flow rate. This flow meter comes in two varieties: non-contact and wetted. The wetted variant is frequently put on a channel's bed, and it has traditionally employed the Doppler Effect to determine velocity. Non-contact varieties are located above the channel and use a radar (for surface velocity only) or a laser (for surface and sub-surface velocities) to measure velocity, with the depth commonly estimated using a look-down ultrasonic sensor. The area x velocity method is used to compute flow rate in an area velocity flow meter for effluent water. This change in frequency is used to calculate the flow velocity.

Electromagnetic Flow Meters: Electromagnetic flow meters are more accurate and repeatable than other flow measuring equipment in the market. Because they are designed without moving parts, they are resistant to abrasion. Even without routine maintenance, these flow monitoring products give years of reliable service. They can also manage high-velocity flows with ease and are unaffected by particulates in the flow stream.

How can we help?

To provide you with the right water purification system for your business, get in touch with Netsol Water. We are one of the leading water treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines like compact sewage treatment plants.

For any assistance or related query,

Call us on +91-965-060-8473;

Or, write us at enquiry@netsolwater.com