What are the different types of clarifiers?

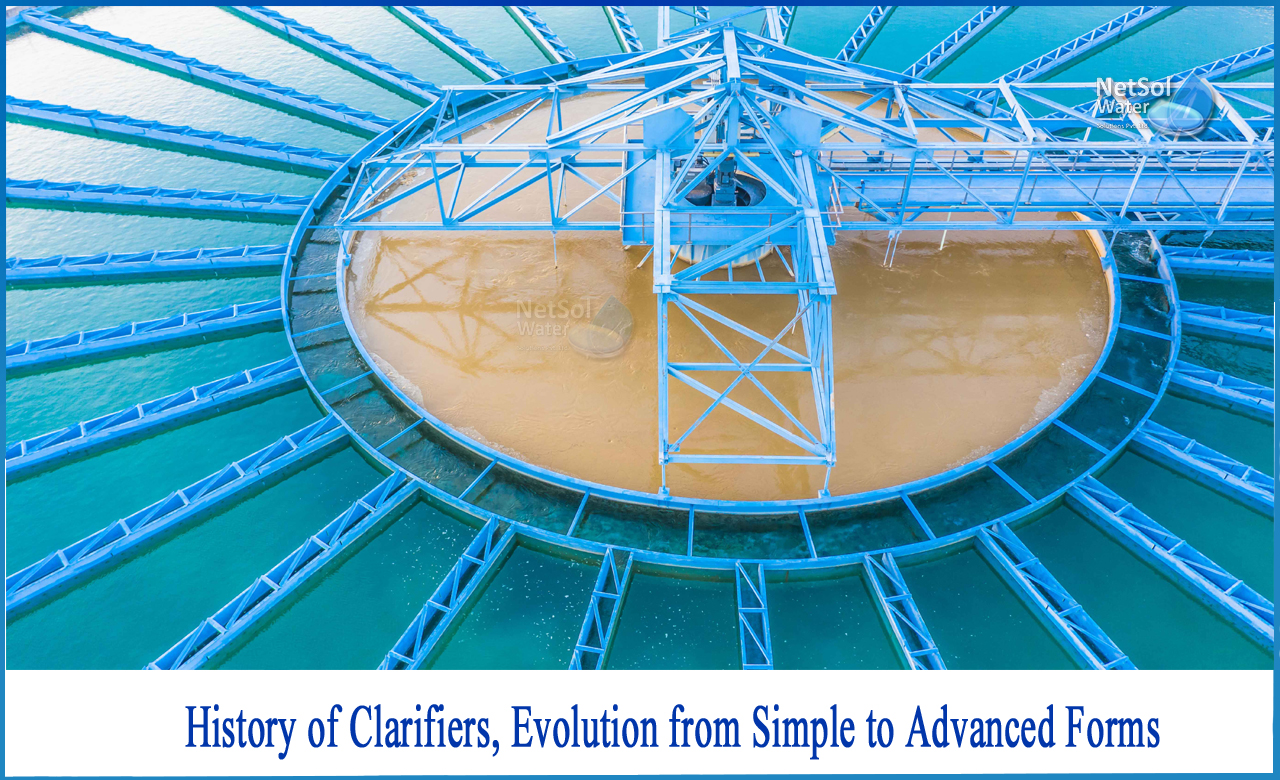

The previous segmented rake blade design has long been considered outmoded, especially for bigger tank diameters where effective delivery of settled materials to the tank centre is more challenging. Primary clarifiers, following fixed film processes, and secondary clarifiers following activated sludge processes have all had success with spiral blade mechanisms. Performance has been good in all applications.

Suction vs. Spiral Blade

When comparing spiral-blade mechanisms to suction mechanisms, it's reasonable to state that spiral-blade mechanisms outperform suction mechanisms. Even yet, some sceptics believe that in secondary clarifiers that treat activated sludge, suction sludge removal devices are preferable to spiral rakes. Almost all of this mistrust stems from a lingering impression based on analogies to ancient segmented rake designs, which were ineffective at transporting settled solids. Suction removal systems do, in fact, outperform old-style segmented scrapers, resulting in shallower sludge blankets and smaller clarifier solids inventory. As a result, nutrient removal facilities have more capacity to handle high flow events and there is less risk of denitrification or secondary phosphorus release.

When old-style segmented scrapers were refitted with spiral rake blades, other investigations showed a similar dramatic reduction in blanket depths. A suction header sludge removal device was compared to a spiral rake mechanism in one study. The sludge blankets were at the same depth as high return activated sludge (RAS) rates, but at reduced return rates, the spiral scrapers produced a lower sludge blanket than the suction system.

Almost every type of clarifier mechanism arm, including old-style segmented rakes, spiral rakes, suction pipe arms, and suction header arms, emits small plumes of light solids. The process biosolids are all quite light, and the clarifier mechanisms are turning at speeds much above the recommended design speeds in every case. Despite the fact that the plumes do not result in a significant rise in effluent total suspended solids (TSS), a simple adjustment in tip speed solves the visual issue in all cases.

Maintenance Is Easier With Spiral Blade Systems

Suction sludge removal techniques demand more maintenance than spiral rake blades. Debris or particles accumulating in the horizontal runs of suction pipes can readily clog them. Suction header orifices can also clog. Grocery bags kept blowing into his clarifiers and plugging the withdrawal orifices, forcing an operator to pull the tanks out of service in order to remove them.

Seals between the revolving and stationary components of the mechanisms are also included in all suction sludge removal systems. These seals wear out frequently, necessitating the removal of the clarifier from service to replace them. According to operators, this always occurs during the rainy season, when the plant's full capacity is required.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.