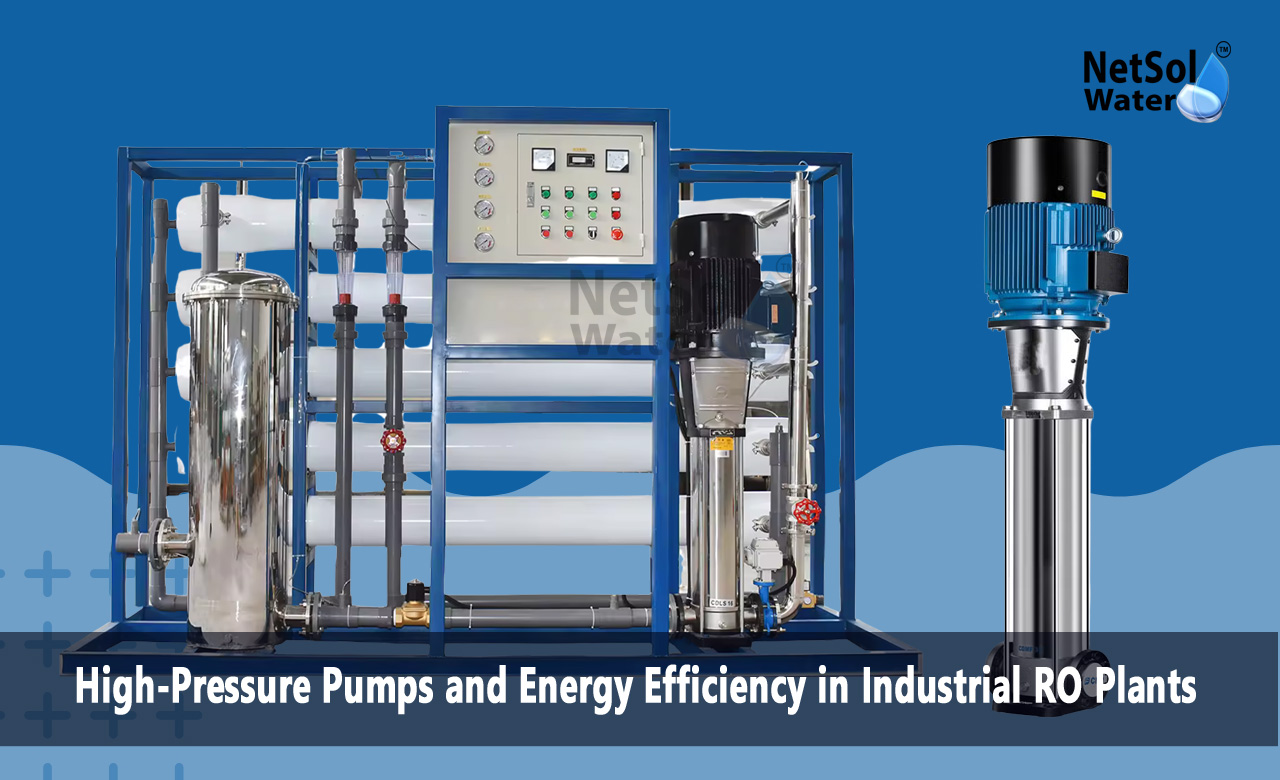

High-Pressure Pumps and Energy Efficiency in Industrial RO Plants

Industrial reverse osmosis systems demand precise water pressure to clean feed water with high output quality. High pressure pumps shape the key performance aspect in such systems. They push water through semipermeable membranes and stand up to high counter pressure in the process. In an industrial RO plant the choice of pump can affect the energy use, the uptime and the maintenance needs. Today the pressure pump choice can shape the overall cost per cubic meter of filtered water. A focus on energy efficient pumps can lower power demand and ease plant load. Such pumps can also help a plant meet green goals and cut carbon output. Many sectors face tougher rules on energy use and push for lower carbon footprints. Netsol Water stands as a leading industrial RO plant manufacturer in the global market. They design pumps that meet precise demands for efficiency and reliability. They deliver machines that lower the cost of operation and raise plant output. Netsol Water uses design methods and quality components that boost pump life and conserve power.

Importance of High-Pressure Pumps in RO Performance

High pressure pumps drive the water through the RO membranes at the required pressure. They ensure that the separation process works efficiently. Without correct pressure the system fails to deliver the desired water quality. Strong pump operation can raise water recovery and lower waste. Let us have a look at some key functions of these pumps.

Pressure Delivery: The pump must reach the right pressure for each stage of the RO process. A mismatch can harm performance. Netsol Water designs pumps that hold steady pressure under varying feed conditions.

Flow Stability: A stable flow rate makes membrane life longer and reduces wear. Pumps that shift output create stress in the system. Netsol Water pumps offer smooth flow even when feed water quality changes.

System Protection: Pumps also protect the system from surges and dry runs. They include safeguards that stop damage to membranes and pipes. Netsol Water adds features that detect abnormal pressure and stop the pump in time.

Pump Design and Energy Use

Pump design shapes the energy footprint of an RO plant. Netsol Water as an industrial RO plant manufacturer shapes pump design to boost efficiency. Each design choice affects motor load power draw and efficiency. A well designed pump cuts energy use and reduces costs in the long run. The design also affects maintenance cycles and cost of ownership. Let us have a look at some design aspects.

Efficiency Curves: Every pump has a chart that shows output versus power use. Staying close to the best efficiency point cuts energy waste. Netsol Water tests each model to map its efficiency curve.

Seal and Bearing Choices: The right seal and bearing reduce friction and leak risk. They lower power loss and cut maintenance time. Netsol Water uses options that last longer in harsh feed water.

Motor Integration: Matching the pump to the correct motor improves energy conversion. Proper integration can prevent losses in the drive train. Netsol Water selects motors that fit each pump model for best performance.

Maintenance Practices for Efficiency

Routine maintenance keeps pumps running at peak efficiency. Over time wear and fouling can reduce performance. A clear upkeep plan can keep energy use low and avoid costly failures. Good upkeep protects the lifespan of the entire RO plant. Let us have a look at some maintenance steps.

Regular Inspection: Inspecting pump components finds early signs of wear. Checking seals bearings and couplings can stop leaks and losses. Netsol Water sets clear schedules for each pump model.

Cleaning Protocols: Cleaning removes scale and debris that raise friction. A clean pump runs smoother and draws less power. Netsol Water provides guidelines on cleaning intervals and methods.

Component Replacement: Replacing worn parts can restore pump efficiency. Using quality spares can extend service life and cut energy need. Netsol Water offers genuine replacement parts for each pump.

Advanced Technologies in Pump Control

New control technologies let operators adjust pump output for best efficiency. They can adapt pressure and flow to match real time demand. These methods can save energy and boost system life. Control systems can track performance and react to changes quickly. Let us have a look at some control strategies.

Variable Frequency Drives: A variable frequency drive changes motor speed to match required load. It can cut power use when full speed is not needed. Netsol Water fits drives that suit each plant need.

Automation Feedback: Automation can monitor pressure flow and energy use in real time. It can adjust pump operation to keep efficiency high. Netsol Water systems include feedback loops that learn from data.

Energy Recovery Devices: Energy recovery devices capture energy from brine and feed it back. They lower the overall power demand of the RO system. Netsol Water integrates these devices for large scale plants.

Conclusion:

High pressure pumps play a core role in energy use in RO plants. As a leading industrial RO plant manufacturer Netsol Water can guide clients to the best pump solution for each need. Work with our team at Netsol Water as your industrial RO plant manufacturer partner. Contact Netsol Water to learn how our pumps can boost your plant efficiency and cut power use. Reach out today to request a consultation or more information.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com