What are the Hidden Costs of Centralized STP Plants?

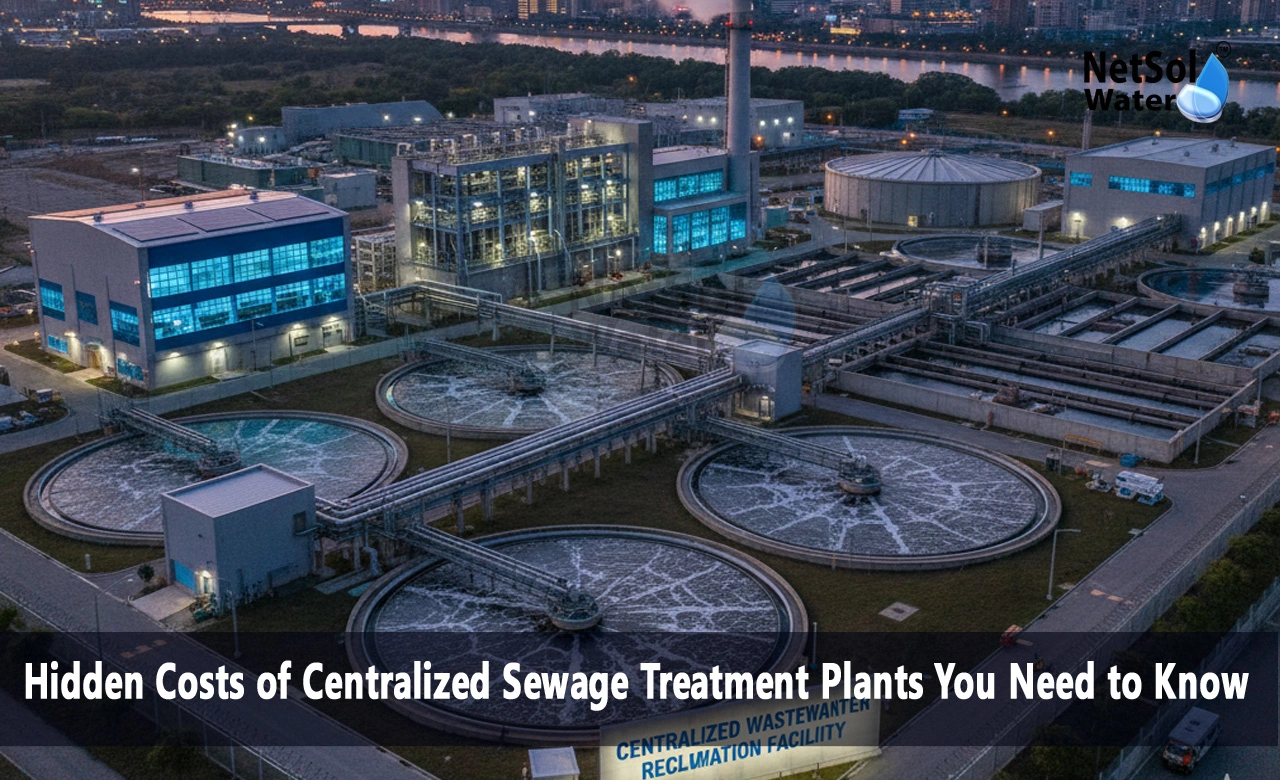

Cities in India grow fast. Places such as Delhi and Noida are known for strong economic activity and many new buildings. They also need good waste treatment plants. A Sewage Treatment Plant helps cities manage dirty water and protect public health. Many developers choose big centralized plants to handle large volumes. These plants seem efficient at first. They promise single point control and lower unit cost. Still they hide costs that owners often miss. Netsol Water is the leading Sewage Treatment Plant Manufacturer and we see these issues on real projects. We will explain hidden costs so planners and owners can make better choices.

Land and Site Preparation Costs

Understanding land and site costs matters because they form a large part of the first bill. A central plant needs a big plot close to the waste source. Cities charge high prices for such land. Let us have a look at some of the expenses that add to the budget.

1: Land acquisition and zoning

Buying or leasing land near urban areas can drain the budget. Planners may face delays while they meet zoning rules. Delays cause higher interest on loans and higher contractor charges. Choosing land far away may lower price but adds long pipes and higher pumping cost.

2: Ground works and soil issues

Site clearing and leveling take time and money. Some plots need heavy earth moving or piling work. Soft soil may require piling or special foundations. Such work adds unexpected costs. If the owner ignores a geotechnical survey early then the project faces change orders later.

3: Access roads and utilities

A central plant needs road access for heavy trucks and frequent maintenance visits. Building an access road and connecting power and water can stretch the budget. Utilities may need upgrades to handle the plant load. These upgrades often come as separate bills from local authorities.

Operational and Energy Costs

Operational cost shapes long term project viability. Many owners focus on initial capital and forget daily running charges. Let us have a look on some of the cost drivers that appear after commissioning.

1: Power consumption and equipment load

Large plants run pumps aerators blowers and mixers for many hours every day. Electricity forms a major share of monthly costs. If the plant uses older motors or lacks energy efficient controls then the bills grow fast. Owners may need to add standby generation for power cuts. Standby generation increases fuel and maintenance expenses.

2: Chemicals and treatment supplies

Some treatment steps need chemicals for pH control, coagulation, disinfection and sludge handling. Chemical prices change with market trends. Over time the cost of supplies can match or exceed other running costs. A central plant uses large volumes so small changes in price hit the budget hard.

3: Skilled staff and monitoring

A big plant needs trained operators and an on site maintenance team. Hiring experienced staff demands higher pay. Continuous monitoring of process and online sensors needs expert review. Many owners try to cut staff and then pay more in fines or emergency repairs. Investing in training and a clear shift plan reduces risk but adds to monthly cost.

Maintenance Upgrades and Long Term Liabilities

Maintenance shapes the life cycle cost of a plant. Owners often assume fixed yearly maintenance only. Let us have a look on some liabilities that surface after a few years.

1: Equipment wear, spares and downtime

Mechanical parts such as pumps, valves and bearings wear out. Spare parts for large plants cost a lot. Long lead time for special parts means longer downtime and higher penalty charges for service interruptions. Downtime can force the use of bypass systems which need extra work and expense.

2: Sludge handling and disposal

Sludge volume grows with time. Central plants must manage dewatering transport and safe disposal. Landfill fees or transport to treatment centers cost money every month. New rules can restrict disposal methods. Owners then face new capital works to meet updated rules.

3: Regulatory updates and upgrades

Regulators update, discharge standards from time to time. A plant built to older standards may need retrofits. New standards may force upgrade of tertiary filters or add disinfection steps. Owners then face heavy upgrade costs and new commissioning work. Planning for future standards reduces surprise but raises initial budget.

4: Community and environmental liabilities

Centralized plants sit near communities. Odour control noise and truck movement can trigger complaints. Community pressure can lead to compensation or additional mitigation works. Poorly managed plants risk fines and loss of public trust. A proactive operation strategy reduces risk but costs more up front.

Conclusion

Hidden costs can turn a Sewage Treatment Plant project into a long term financial burden. A clear view of land costs energy use maintenance and regulatory risks helps owners choose the right solution. Netsol Water is the leading Sewage Treatment Plant Manufacturer and we help clients assess these cost items early. If you plan a central plant or want a second opinion contact us for a detailed study or request a consultation. Act now to avoid surprises later and to keep your project on budget.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com