Difference between Forward Osmosis vs. Reverse Osmosis

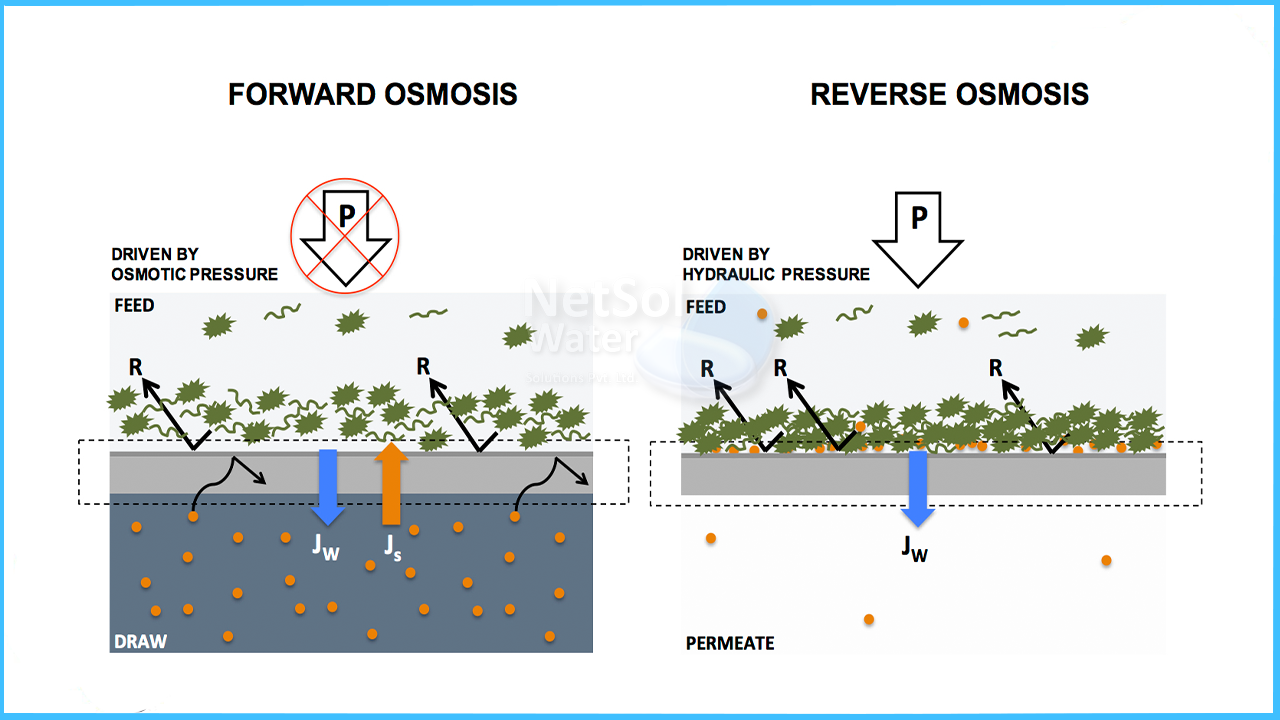

Forward osmosis (FO) and reverse osmosis (RO) have substantial differences. When comparing the advantages of forward osmosis vs. reverse osmosis for industrial wastewater treatment, it's crucial to remember each technology's strengths and disadvantages. Both technologies are used to diffuse wastewater, while filtering away dissolved solids, ions, and other unwanted chemicals, from one side of a membrane to the other. The way water is forced through the membrane in reverse osmosis and forward osmosis differs significantly.

Water is driven across the membranes using hydraulic pressure to overcome the natural osmotic pressure in reverse osmosis. The higher the feed solution's salinity, the more pressure is required. As a result, high-pressure pumps and vessels containing large amounts of energy are required.

Reverse osmosis also necessitates membranes that are specifically developed for the job, such as brackish water membranes, seawater membranes, high-pressure or ultra-high-pressure membranes with working pressures ranging from 1,000 to 1,740 psi and brine with TDS of up to 75,000 ppm. Because of the pressure requirements, reverse osmosis becomes less feasible when brine TDS values approach 75,000 ppm.

By running a highly saline draw solution on the other side of the membrane, forward osmosis exploits natural osmotic pressure to stimulate the flow of water through the membrane. This implies the feed solution passes through the membrane at a low pressure, offsetting the requirement for high-pressure hydraulics. This is the primary distinction between forward osmosis and reverse osmosis.

SCALING AND FOULING-

Fouling and scaling are well-known problems with reverse osmosis membranes, in which organic and chemical residue, oxidants, and scaling ions accumulate on the membrane surface. This diminishes the membrane's efficacy and necessitates periodic maintenance and backwashing. A reverse osmosis membrane should ideally only handle water and pure salt, however this is rarely the case due to the complicated composition of industrial wastewater effluent.

The low pressure of the feed solution in forward osmosis makes the Forward Osmosis membrane less susceptible to fouling and scaling problems. This decreases the requirement for membrane cleaning and extends the membrane's lifespan.

To extract clean water from contaminated water sources, membrane-based water filtration devices and processes require energy. Traditional hydraulic pressure-driven procedures such as reverse osmosis, nano-filtration, ultra-filtration, and micro-filtration require electrical energy, whereas forward osmosis technologies require chemical energy.

Water is transported across a semi-permeable membrane in reverse osmosis water filtration against the osmotic pressure gradient between the feed (high osmotic pressure) and permeate (low osmotic pressure) streams by hydraulic pressure. The permeate (purified water) and a concentrated impaired water source are the results of reverse osmosis water purification (the retentate or RO brine).

In forward osmosis water filtration, an osmotic pressure gradient between the feed (low osmotic pressure) and draw (high osmotic pressure) streams, drives water transport across a semi-permeable membrane. A draw stream diluted with cleaned water (the permeate) and a concentrated feed stream are the outputs of forward osmosis water filtration.

Because of this fundamental difference in energy requirements, forward osmosis processes require up to 90% less energy to move water than reverse osmosis processes.