How is wastewater treated in the dairy industry?

Dairy industry have grown in most nations due to increased demand for milk and milk products. Raw milk is processed into pasteurized and sour milk, yoghurt, hard, soft, and cottage cheese, cream and butter products, ice cream, milk and whey powders, lactose, condensed milk, and a variety of sweets, which are all part of the dairy business.

Effect of dairy wastewater on the Environment

The environment is impacted at every step of the dairy supply chain, including production, processing, packaging, shipping, storage, distribution, and marketing. Milk and dairy products are examples of industrial effluent sources that pollute natural aquatic habitats significantly. Because of the industry's diversity, numerous product processing, handling, and packing processes generate wastes of varying quality and quantity, which, if not managed, could result in increasing disposal and serious environmental issues. In many countries, the dairy industry is widely regarded as the major contributor of food processing effluent.

The issue for most dairy operations is that wastewater treatment is seen as a necessary evil, tying up valuable money that could be better spent on core business activities.

Issues due to disposal of dairy wastewater

Dairy wastewater disposal typically causes one of three issues:

(a) High treatment levies, levied by local governments for industrial wastewater;

(b) Pollution may occur when untreated wastewater is discharged into the environment or used directly as irrigation water; and

(c) Sludge disposal for dairy plants that have already installed an aerobic biological system.

Goals of dairy wastewater treatment

The treatment of dairy wastes has the following goals:

1. Reduce the waste-organic water's content,

2. Remove or reduce nutrients that could pollute receiving surface waters or groundwater, and

3. Remove or deactivate the potential pathogenic microorganisms or parasites.

Dairy Industry's Effluent Treatment

The wastewaters produced by this sector contain significant amounts of nutrients, chemical oxygen demand (COD), biological oxygen demand (BOD), total suspended solids (TSS), and organic and inorganic substances, which, if not properly handled, can create serious environmental problems.

A series of steps are followed at the dairy wastewater treatment plant:

1. The pH level is initially brought to 8.5 using pH controllers such as caustic or acid. Any emulsions are then broken down and solids precipitated with the help of a de-emulsifier.

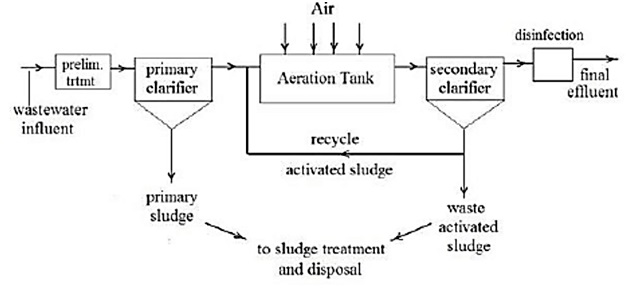

Flowchart showing treatment of dairy processing wastewater

2. Flocculation and Dissolved Air Flotation are two more crucial processes in the dairy wastewater treatment process. The wastewater is flocculated and then pumped into a slow mix zone, where the particles are clumped together into larger ones before being treated with the air flotation procedure.

3. The air flotation system bubbles are driven from a Recycle Air Dissolving system that blows the treated effluent into the air flotation system.

4. The sludge is then run through the filter press and disposed of in accordance with environmental requirements.

Conclusion

To reduce the amount of dairy wastewater that needs to be treated and treatment costs, the dairy plant must pay close attention to limiting milk and milk product losses. The dairy plant operators should be able to operate profitably while also meeting environmental criteria if they practice good product conservation and choose an effective waste treatment process.

What do we have to offer?

Netsol Water is one of the leading water and wastewater treatment companies in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, ETP manufacturing, Industrial & Commercial RO Plant manufacturing, among other services. The company designs and manufactures all in one system’s that are ideal for treating wastewater and the sludge generated.

Our water and wastewater treatment plants we create are tailored to each client's specific requirements. For specialty areas such as dairy industry and many more, you can rely on us for the best technologies and solutions!