What are the phases involved in anaerobic degradation?

Anaerobic Digestion is the system wherein microorganism’s biodegrade natural materials together with stable animal manure, bio-waste and other wastes in the absence of oxygen.

Anaerobic Digestion for biogas manufacturing is performed in sealed gadgets known as digesters, which might be designed and constructed in distinct sizes relying at the kinds of feedstock and loading amount. These digester tanks include complicated bacterial cultures that destroy down (digest) the waste to provide biogas and digestate.

Several kinds of natural materials (feedstocks) may be blended collectively in a single digester. This is called Co-Digestion. Co-digestion can boom biogas manufacturing from low-yielding or difficult-to-digest natural wastes.

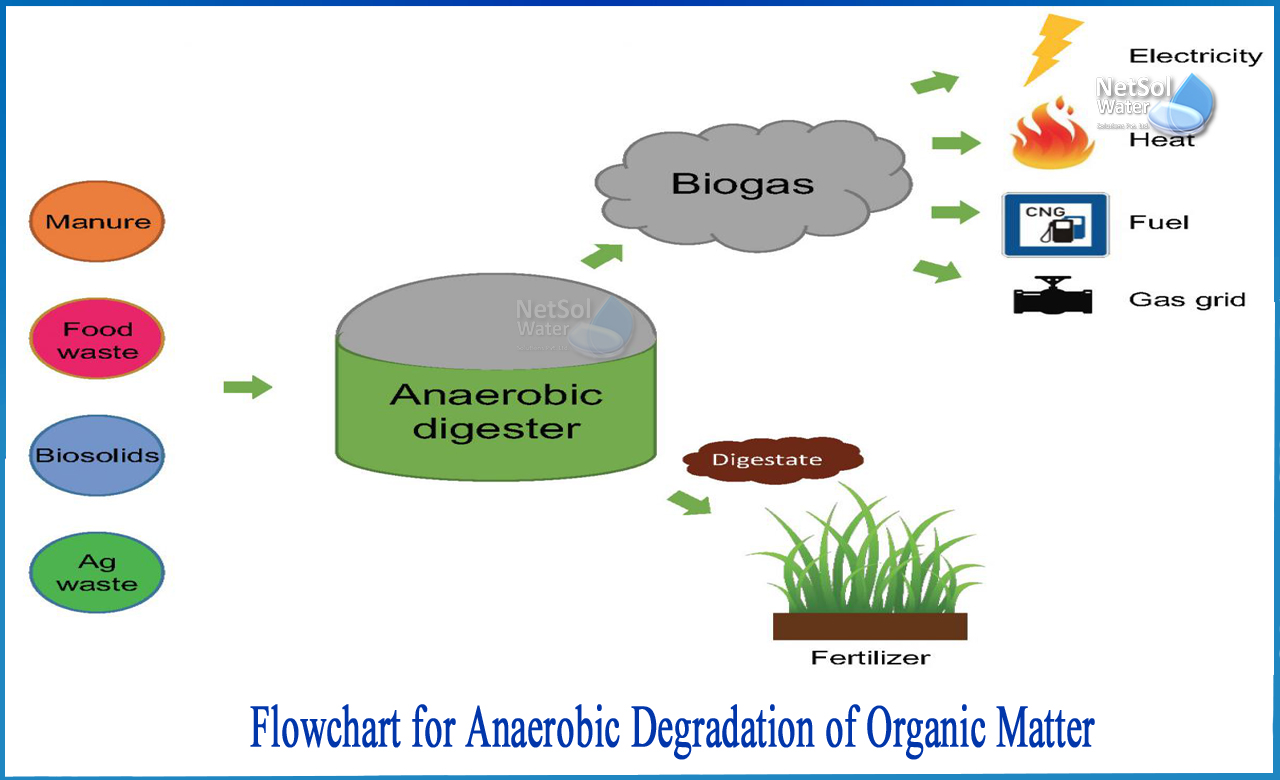

Flowchart for Anaerobic Digestion

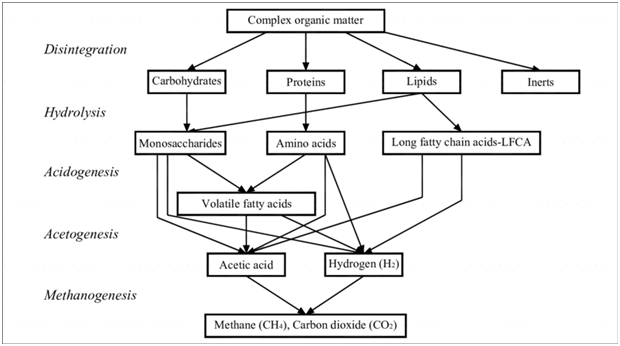

1. Complex Organic Matter: Digestion starts by breaking up of complex organic matter into its constituent’s carbohydrates, proteins, lipids and inert matter. This process is called disintegration.

2. Hydrolysis: The broken carbohydrates are converted into monosaccharide’s by the hydrolysis of the organic matter constituents. Lipids are converted into monosaccharide and long fatty chain acids. Protein is hydrolyzed into amino acids.

3. Acidogenesis: The third step of anaerobic digestion is conversion of Monosaccharide’sand amino acids to volatile fatty acids.

4. Acetogenesis: The fourth step converts volatile fatty acids and long fatty chain acids into acetic acid and hydrogen.

5. Methanogenesis: This is the last and final step of anaerobic digestion which converts acetic acid and hydrogen into methane and carbon dioxide.This methane is used as a bio fuel.

Anaerobic Digestion produces treasured outputs: Biogas and Digestate

Biogas includes a pretty excessive percentage (50-75%) of methane (CH4), the primary factor of natural fuel, in addition to carbon dioxide (CO2), hydrogen sulphide (H2S), water vapour, and lines of different gases. Like herbal fuel, the electricity contained in biogas may be used to generate heat and electricity. Also, biogas can be purified through doing away with the inert or low-fee components (CO2, water, H2S, etc.) to provide renewable natural gas (RNG). This may be bought and injected into the distribution systems, compressed and used as automobile fuel, or in addition processed to provide opportunity fuels, electricity products, or different superior biochemical’s and bio products.

Digestate is the leftover cloth after the digestion system. With suitable treatment, the digestate may be used in lots of beneficial applications, as a nutrient-wealthy fertilizer, as organically enriched compost, or absolutely as a soil improver.

How can Netsol Water help?

Netsol is India’s leading waste water and water treatment solution company which covers all the needs of any water treatment scheme on all levels. We have the expertise to provide waste water solutions at domestic, industrial and municipal level.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.