What is BAF treatment for coal mine WWTP?

The biological aerated filter (BAF) was the first to be invented in Europe and America, and it is now extensively used in industrialized nations including Europe, the United States, and Japan.

Process involved in Biological Aerated Filters

Various purification functions, like as filtration, adsorption, and biological metabolism, are integrated into this technique. Wastewater enters the filter material layer from the bottom of the filter tank, and the lower half of the filter material layer has an aeration system for oxygen delivery, with air and water flowing in the same direction. Organic matter is oxidized and degraded by microorganisms in the filter tank, and NH3-N is oxidized to NO3-N; also, part of the nitrification is performed at the same time owing to the anaerobic/anoxic condition between the stacked filter layer and the microbial membrane.The effluent from the upper half of the filter can be immediately released from the system after denitrification.

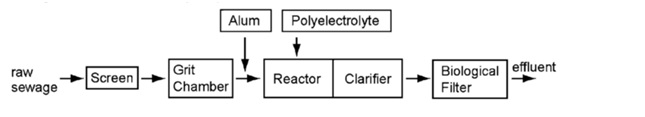

Flow chart for BAF treatment in coal mines

Features of the BAF process

In comparison to the classic activated sludge and contact oxidation methods, BAF as a novel membrane wastewater treatment technique offers the following advantages:

1: The biological concentration and organic load are both increased,

2: The coarse and porous spherical filter material used in the aerated biological filter provides a better growing environment for microorganisms,

3: It is easy to hang and operate, and can sustain more biomass on the surface of the filter material and between the filter material.

4: The number of microorganisms is significantly higher than in the activated sludge process (up to 1015g/l).

5: The procedure is straightforward, and the effluent quality is satisfactory. The SS of the effluent is extremely low, typically not surpassing 15mg/l, due to mechanical retention of the filter material, adsorption created by microorganisms on the surface of the filter material, and viscous chemicals produced during metabolism.

6: The biofilm may be successfully replenished thanks to periodic backwashing, resulting in a biofilm that is thinner and more active. Even if the biological treatment fails, the physical mechanism of the treatment can still provide high-quality water in a short amount of time. BAF's treated effluent not only fulfils emission regulations, but it may also be reused.

7: Impact load resistance is high. It is less susceptible to variations in organic load and hydraulic load than standard activated sludge, and there is no sludge expansion problem, thanks to the high concentration of microorganisms scattered throughout the filter tank.

8: The distribution of microorganisms in the classic activated sludge process is rather uniform, however with BAF, distinct dominating strains grow from top to bottom, allowing carbon removal and nitrification/denitrification to occur in the same pond.

9: Denitrification impact is good. The filter may conduct nitrification and denitrification while removing carbon by combining multiple filter functions or distributing different functional zones inside the same filter. The concept is to artificially establish aerobic and facultative biological habitats in two sets of filters or in the same filter, which can remove general organic matter and suspended particles while also improving denitrification.

Conclusion

Small size, low land occupation, good water quality, high efficiency, easy operation, simple process, and management, and so on are all advantages of the biological aerated filter process. In practice, it can perform both centralized and on-site manual automated control. Day by day, it has matured to the point that its effluent, once treated, can meet the criteria of reclaimed water. The quality and amount of wastewater from coal mines varies widely, with low contaminant concentrations and good biodegradability.

Technical assistance and guidance!

Netsol Water collaborates with a wide range of international organizations to tackle complicated wastewater problems by strategically integrating modern treatment technology with practical solutions.

Call us if you want the best wastewater treatment system for your home or business. Our services include Commercial RO Plants, Industrial RO Plants, STPs, ETPs, as well as a variety of useful after-sales services. Our professionals will check the customer's location first, then explain the available options and thus, allow you to select what is best for your property. You can always find useful information by liking and following us on YouTube and LinkedIn.

For further inquiries or product-purchase-related questions, give us a call on +91-9650608473 or email at enquiry@netsolwater.com