Overview

Sludge is unwelcomed but unavoidable byproduct of industrial wastewater treatment. The methods used by facilities to handle and dispose of sludge have a significant impact on operating costs because excess water in solids directly influences haul-off costs. It's difficult to remove as much water as possible from waste because more water means higher disposal costs.

Methods of Sludge Dewatering

There are numerous methods for dewatering sludge, each with its own set of advantages.

A vacuum system and a filter press are two of the more popular methods.

It is a widely held, but unproven, belief that a vacuum filter facilitates a more automated procedure. This is untrue. A vacuum system targets lower solids, resulting in more water in the sludge and higher haul-off costs. It's also a costly system to run, with pre-coat costs. The upkeep of vacuum seals and the system's numerous moving parts adds to the costs.

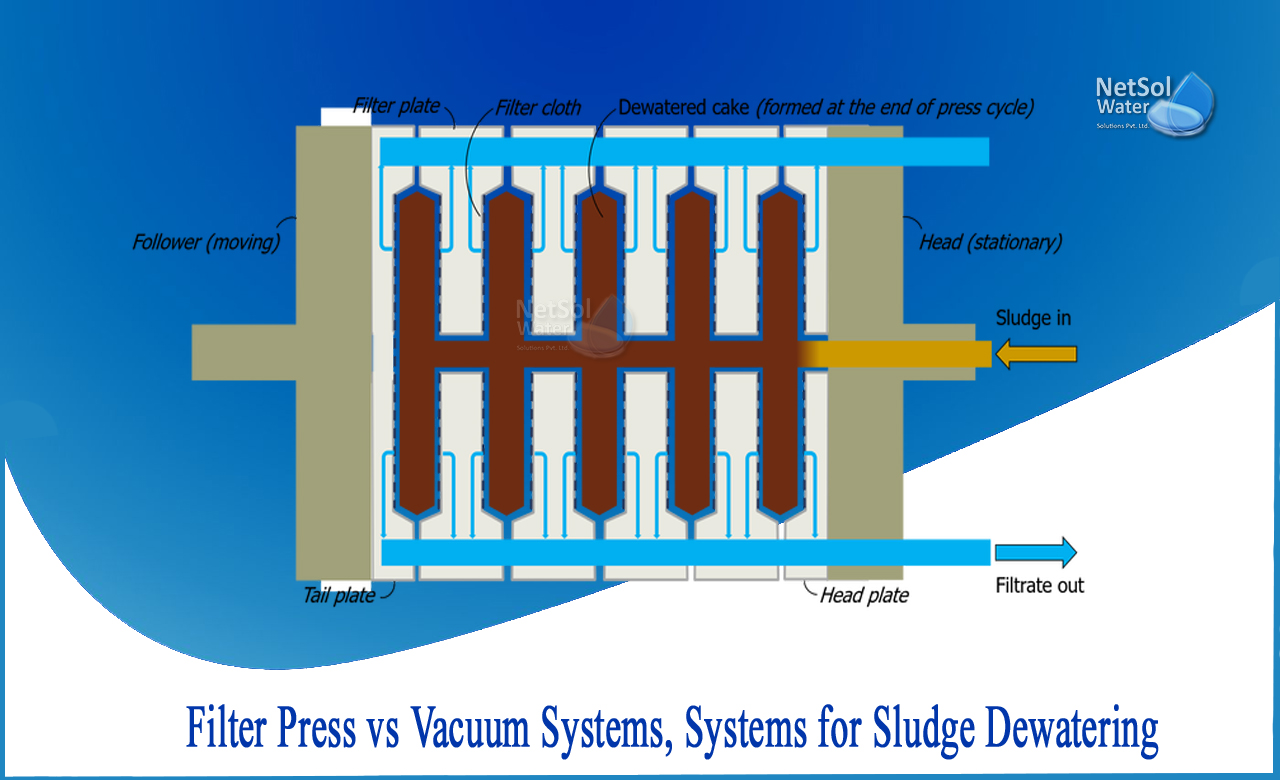

Dewatering with a filter press directs higher solids and yields less water in the waste, lowering haul-off costs. A filter system also lowers operational costs and aids automatic stage fill sections. To maintain the maximum feed volume, the system continuously adjusts feed pressure. By preventing premature plate surface blinding, which causes soft cakes, the press fills uniformly and provides optimal dewatering.

Netsol Water envisions a day when wastewater systems are simple and successful. Our comprehensive approach to wastewater treatment includes design, installation, and service, as well as providing the appropriate chemicals and increasing chemistry dosage.

What are the advantages of Filter press over vacuum systems?

1. Special sludge can be processed using a belt filter press

Some sludge, for example, railway sludge, oil sludge, and sludge produced by diatomite treatment of wastewater. Other types of filter presses cannot process well, but the belt filter press can.

2. Low energy bills

Under the same conditions, the belt filter press has the same treatment effect as other filter presses, but its water and power consumption is only one-third that of other equipment.

3. Occupation of a small area

The belt filter press takes up only half of the equipment due to its unique design but provides the same treatment as other filter presses.

4.Stability of operation and long service life

The filter belt used with the machine is both strong and short in length. It is difficult to damage due to the unique adjustment structure. The filter belt has a long service life and runs smoothly. Instead of traditional carbon steel bearings, high-strength stainless steel bearings are used. The corrosion resistance is greatly improved, and the equipment's service life can reach ten years.

5.Easy to use

The operation of the belt filter press is not as complicated as that of other filter presses due to its simple structure and reasonable design; even inexperienced workers can operate it.

Conclusion

When it comes to dewatering sludge, industrial facilities have many affordable options. Techniques such as an extractor, belt press, geotextile, and rotary vacuum can all be used. The goal of each is to separate sludge into liquids and solids while removing as much water as possible from the byproduct to reduce disposal costs.

Contact a Netsol Water professional today to learn more about our dewatering methods.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.