What are the Features and advantages of MBR Systems?

It is commonly accepted that traditional systems use gravity separation as a method of achieving the treatment standard. MBR systems due to its dependence on gravity settlement, followed by sand filtration, solves these operational issues, in order to meet the environmental regulations associated with the release of cleaned wastewaters, as well as the strict standards you demand for water re-utilization.

In addition to solving these operational issues, MBR also achieves discharge criteria that are unattainable using conventional techniques.

Advantages of Membrane bio-reactor systems

Several useful advantages of the MBR Process are listed below:-

· A smaller footprint

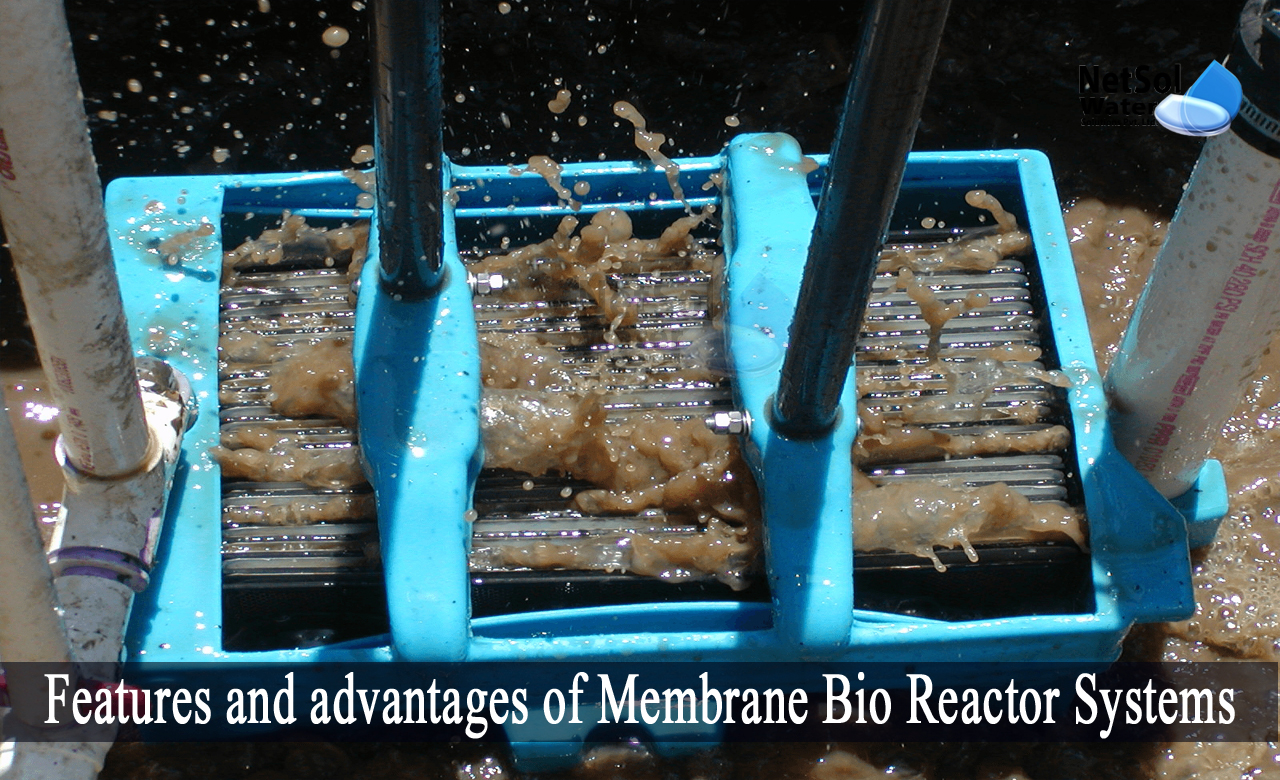

Clarifiers are no longer required. The membrane modules are housed in a smaller, rectangular-shaped tank that substitutes the clarifier, whose size is determined by the flow and operational mixed liquor level, of the aeration tank.

MBR system can function at very high levels of MLSS (mixed Liquor Suspended Solids), typically in the range of 12,000–18,000 mg/l, and as high as 22,000 mg/l. This is because the MBR system does not require the activated sludge flock to be formed, in the bioreactor needed for elimination by settlement.

As a result, as compared to a conventional system, which must operate at a concentration of between 3,500 and 5,000 mg/l, the bioreactor's physical size is comparable to that of the conventional system, or one third of the operating volume.

Design of bio-reactors for MBR Systems

Our bioreactors are designed to operate at MLSS of 10,000 mg/l. Therefore, the ability to operate them consistently at 15,000–18,000 mg/l means that, corresponding increases in COD/BOD loads can be made under control, i.e., approximately 50% spare treatment capacity, when seasonal differences in crop and production occur.

· Outflow excellence

The biomass, which includes trapped and combined inorganic and organic micro-contaminants, pathogens, viruses, and macromolecules, is completely retained in the biological systems, and is subjected to a longer treatment time. This advantage may be necessary in light of the more stringent effluent quality requirements.

· Lower distribution costs for sludge

By operating the bioreactor at this high degree of absorption, a lengthy sludge age is produced, which significantly minimizes the amount of sludge that must be removed from the site, after being wasted out of the system.

Conclusion

Having no solids in the cleaned effluent and eliminating sand filters from the system, has many process and operational benefits. First, the total treatment volumes are reduced, because no sand filter backwash waters are produced. Second, the life expectancy of the activated carbon will be much higher, because the solids passed by sand filters will present an organic load that will be rejected by the activated carbon, shortening its life expectancy.

Zero solids indicate that UV disinfection is not necessary, because UV is intended to eliminate particle bacteria components.

Netsol’s MBR Systems Service

For services related to MBR, Netsol Water is a leading provider of technologically sophisticated wastewater treatment solutions. We are professionals at providing our valued clients with the highest-quality MBR systems, and integrating them into their new and current facilities, as needed. For more automation and more effective treatment, our premium MBR systems are designed, and produced in-house.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.