What happens to the sludge in secondary treatment?

Activated sludge process (ASP) and Trickling Filter are two examples of traditional biological wastewater treatments under aerobic conditions. In 1914, the ASP was created in England.

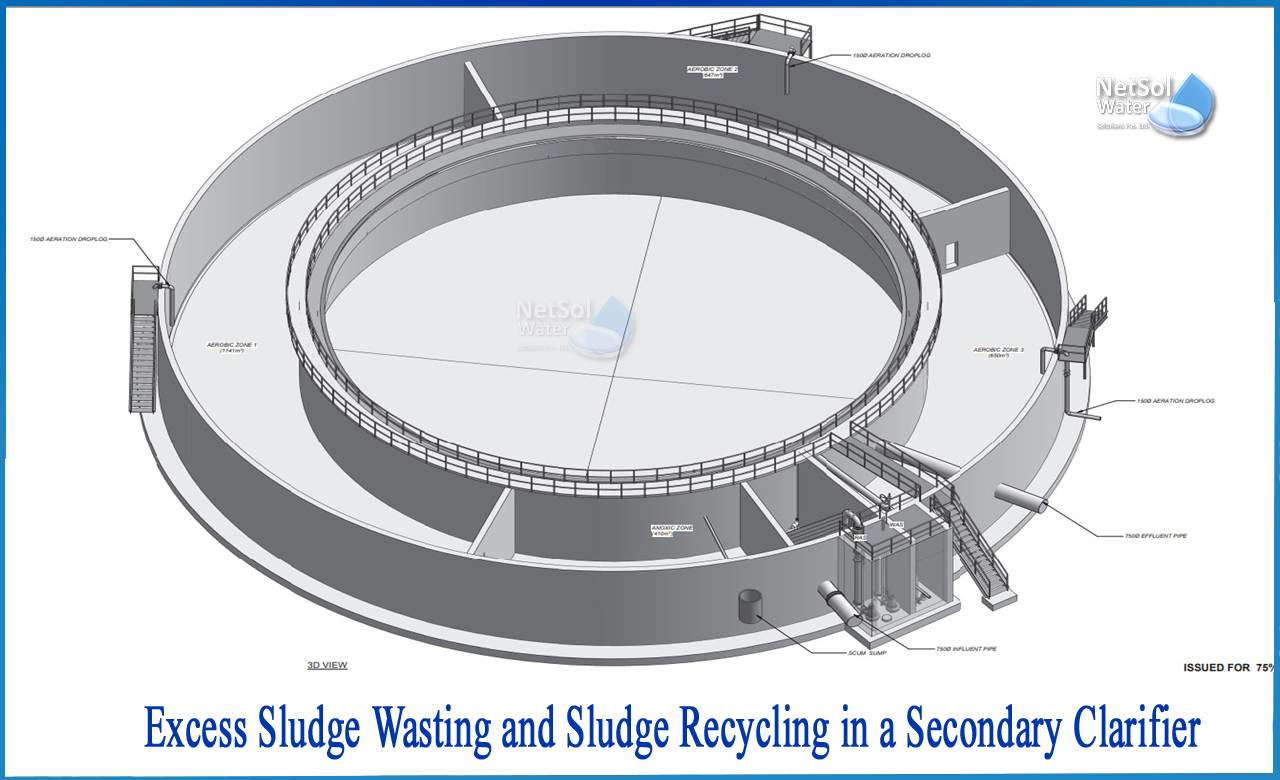

The activated sludge process consists of an aeration tank, where organic matter is stabilized by the action of bacteria under aeration, and a secondary sedimentation tank (SST), where the biological cell mass is separated from the aeration tank effluent, and the settled sludge is recycled partly to the aeration tank and the remainder is wasted. The activated sludge process necessitates recycling. Diffused or mechanical aeration is utilized to produce the desired aeration conditions.

Diffusers are installed at the tank's bottom, and mechanical aerators are installed on the water's surface, either floating or permanent. In the event of diffused air aeration, settled raw wastewater and returning sludge enter the tank's head and traverse the tank in a spiral flow pattern, or get totally mixed in the case of a completely mixed reactor.

In the case of a plug flow aeration tank, the air supply can be tapered throughout the length to meet the amount of oxygen demand. In the settling tank, the effluent settles, and the sludge is returned at a fixed pace.

What is Excess sludge wasting?

To maintain a constant level of MLSS in the system, the surplus sludge left in the secondary clarifier after being returned to the aeration basin must be squandered. The amount of surplus sludge increases as the F/M ratio rises and decreases as the temperature rises. Excess sludge can be disposed of as mixed liquor through the sludge waste line or straight from the aeration basin. Although it is common to discard sludge from the sludge return line, it is preferable to dump surplus sludge from the aeration basin for better plant management.

Sludge waste from the aeration basin is also useful for following sludge thickening processes, since dilute mixed liquor may thicken to greater solid concentrations than concentrated sludge.

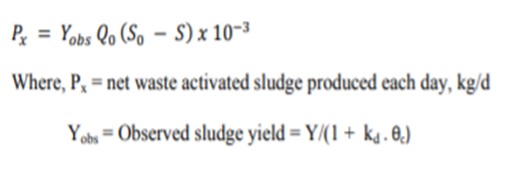

The excess sludge generation under steady state may be estimated from following equation:

What is Sludge recycling?

The MLSS concentration in the aeration tank is regulated by the sludge recirculation rate as well as the secondary clarifier's sludge settleability and thickening.

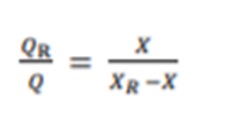

The recirculation ratio is calculated as follows, taking into account the mass of microorganisms entering and exiting the aeration tank:

Where,‘Q’ is the wastewater flow rate,‘QR’ is the recycling rate, ‘X’ is the MLVSS concentration in the aeration tank, and ‘XR’ is the VSS concentration in the return sludge.

The sludge volume index determines sludge settleability (SVI).

If suspended solids sedimentation in the laboratory is considered to be identical to that in the secondary clarifier, then

XR = (VSS/SS ratio) 106 /SVI

SVI values between 50 and 150 mL/g suggests that the suspended particles have settled well. Unless additional thickeners are installed to concentrate the settled solids or a secondary clarifier is designed to have a higher value, the XR value should not exceed 10000 g/m3.

How can Netsol Water help?

If you want to know more about the aeration in secondary treatment of wastewater, you are at the right place! Netsol Water is the leading name for water and wastewater treatment plants manufacturer. Our products are equipped with the most precise and latest technology, thus you can rely on us.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.