Overview

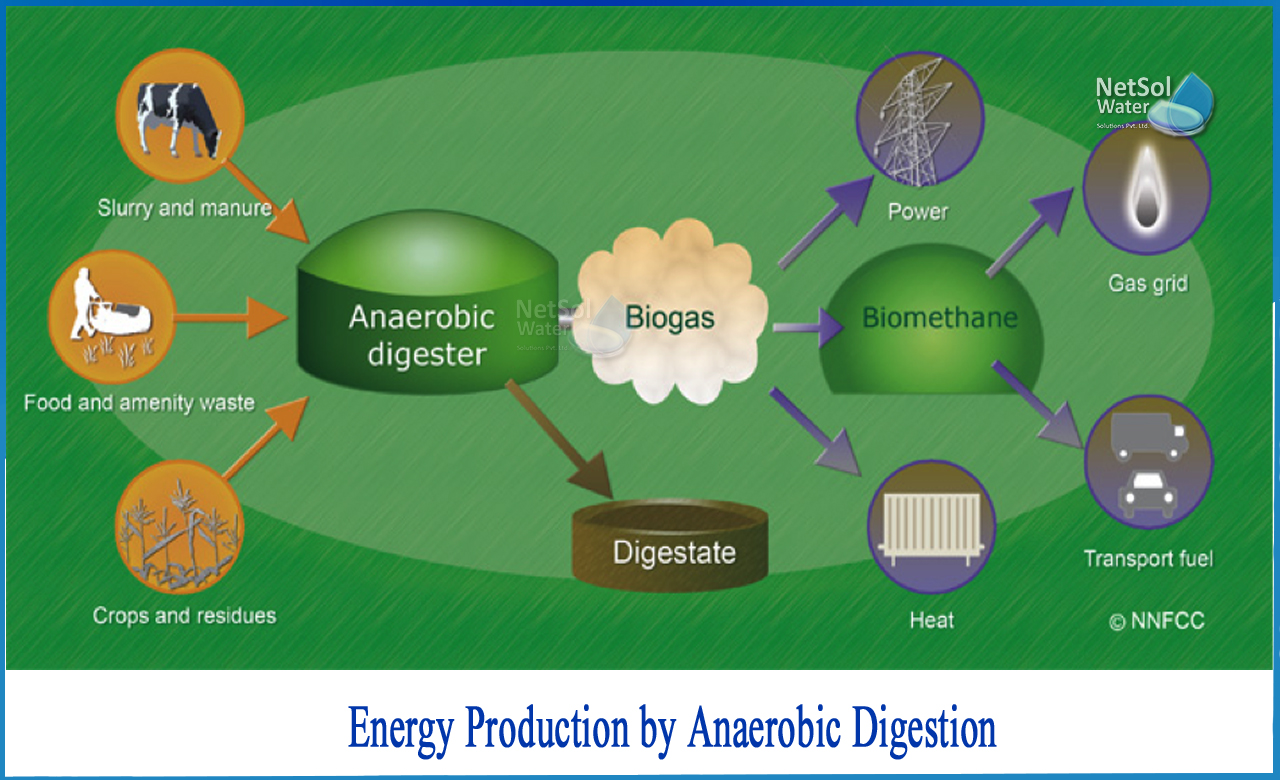

Anaerobic digestion is a waste treatment procedure that uses bacteria that thrive in the absence of oxygen to break down organic debris. Manure, sewage biosolids, and food wastes can all be used as feedstocks. One of the benefits of anaerobic digestion is its capacity to handle high-load streams while creating useful products such as energy. Anaerobic digestion can generate far more energy than is necessary to run the process.

Biogas generation is the most successful kind of anaerobic digestion energy recovery. Biogas is composed of 50-75 percent methane, the primary component of natural gas. Although biogas contains carbon dioxide, it is considered carbon-neutral since the carbon is derived from plant materials and biomethane replaces the use of fossil fuels. Hydrogen sulfide, water vapour, and tiny amounts of other gases are also present in biogas.

Purifying methane in biogas yields another form of natural gas, known as biom?ethane, which may be utilized interchangeably with natural gas and even incorporated into the natural gas distribution system.

What exactly is biogas?

Biogas is created when bacteria break down organic materials (plant and animal products) in an oxygen-free environment, a process known as anaerobic digestion. Anaerobic digestion is used in biogas systems to recycle organic waste, converting them into biogas, which includes both energy (gas) and useful soil products (liquids and solids).

High-Load Stream Treatment

Even in the absence of energy recovery, anaerobic digestion is a strong wastewater treatment procedure for difficult-to-treat wastewater streams with significant nutrient loads. When combined with energy recovery, the benefits grow.

Energy Yields Vary

The parameters of the feedstock are critical for anaerobic digestion energy recovery.

The following characteristics have a significant impact on energy yields:

- Total solids

- Water content

- Solids that are flammable

- Size of the particles

- Biodegradability

- Demand for Chemical Oxygen (COD)

Temperatures, hydraulic retention time, mixing duration, loading rate, pH, and pretreatment are all critical factors to consider. Smaller digesters, for example, often result in shorter retention durations, which reduces biogas output.

How to produced energy by anaerobic digestion?

Although most organic materials may be digested anaerobically, high digestibility is critical for success, and yield from more difficult-to-digest feedstocks can be improved by mixing them with other feedstocks, a process known as co-digestion.

When there is insufficient trash on-site to make energy recovery appealing, anaerobic digestion plants can collaborate with other local waste sources to undertake co-digestion and expand digester capacity and retention durations, hence improving yields. The potential output of a feedstock typically increases with greater dry matter content, including food waste, which is an appropriate substrate for co-digestion.

Conclusion

Many wastewater treatment facilities (WWTP) currently have anaerobic digesters on-site to handle sewage sludge, the solids removed during the treatment process. However, many WWTPs lack the necessary technology to utilise the biogas they generate and instead flare it.

If all of the facilities that currently use anaerobic digestion—which treat over 5 million gallons per day—installed an energy recovery facility, India could reduce annual carbon dioxide emissions by 2.3 million metric tons, which is equivalent to the annual emissions from 430,000 passenger vehicles.

How can Netsol Water help?

Netsol Water is a large water and wastewater treatment company in India that manufactures WTP, WWTP, STP, ETP, RO Plants, among other services. It has become our job to rescue the earth. The firm manufactures equipment’s and is dedicated to offering practical solutions that enable businesses to thrive. We are dedicated to delivering hands-on service, professional advice, and training to our valued clients.We have a solution to every environmental concern and its management.

Anaerobic digestion is an appealing choice if a sufficient volume of the appropriate feedstock is available. On-site energy savings or revenues from biogas sales make anaerobic digestion an appealing option. Netsol Water Solutions recovers energy in a variety of sectors throughout India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.