Electrocoagulation to Remove Tough Pollutants in STP Plant

The electrocoagulation method helps remove substances that resist normal treatment. Municipal plants face rising loads of industrial chemicals, microplastics and heavy metals. These substances pass through filters and cause harm to rivers and soil. Electrocoagulation works by generating charged particles that bind with pollutants. Once bound the particles form larger clumps that sink or float for easy removal. Many engineers now study this method to improve plant outcomes and meet stricter rules. The process can cut down on chemical use and reduce sludge volume. It can also handle oil-based waste dyes and small suspended solids. Plant operators find it useful when conventional steps fail to reach set targets.

How the Process Works?

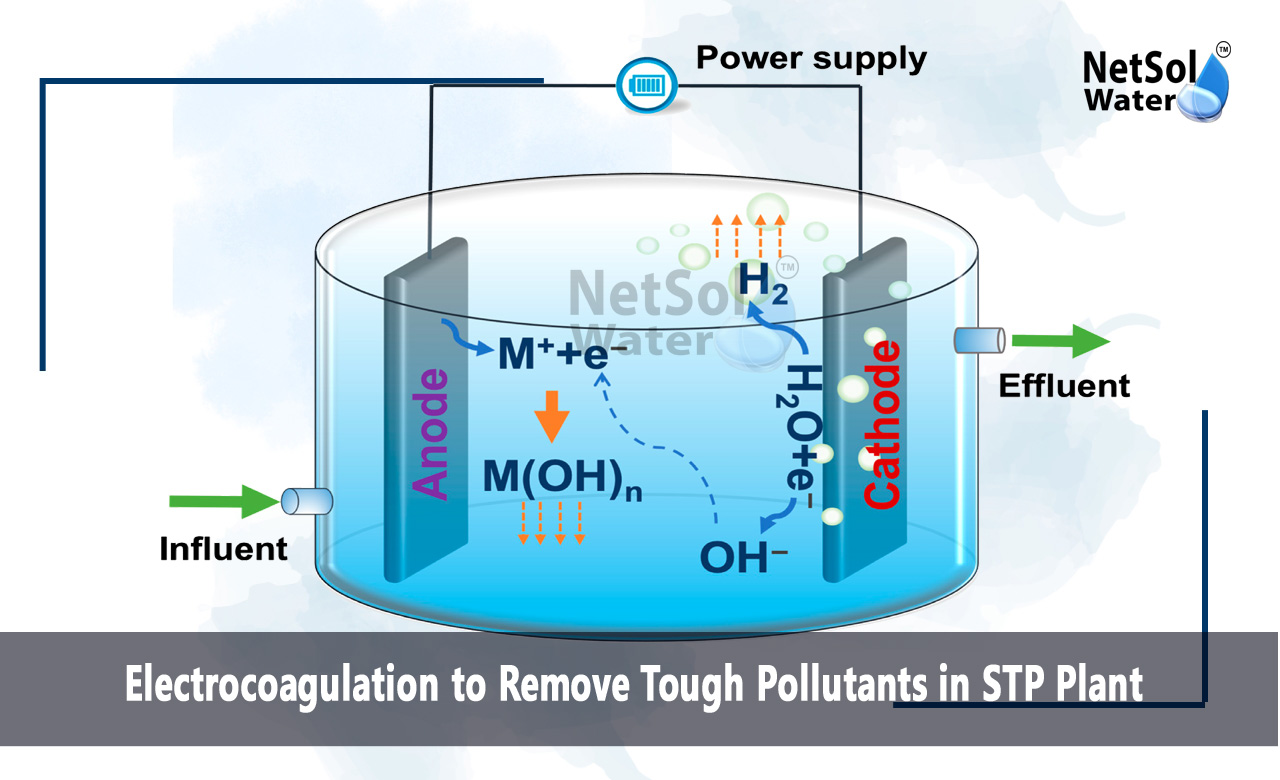

Electrocoagulation uses an electrical current across metal electrodes. The current dissolves small amounts of metal into water. These metal ions form hydroxides that attract pollutants. The process causes fine particles to join and form larger masses. Operators can then remove these masses with settling screens or flotation.

Electrode Action and Reactions

Electrode material dictates which ions enter the water. Aluminium and iron work well in many cases. They produce different flocs that bind distinct pollutant types. Adjusting current and time changes the removal speed. Operators must monitor voltage cell spacing and flow rate to keep reactions stable.

Pollutant Capture

Charged flocs attach to dissolved organics, heavy metals and emulsified oil. The flocs increase particle size so physical separation becomes easier. This step reduces load on later filters and lowers chemical dosing needs. The capture step links directly to the electrode choice and the current settings.

Read: Sewage Treatment Plant Manufacturer

Effectiveness Against Tough Pollutants

Understanding how electrocoagulation removes stubborn pollutants helps choose the right plant mix. Many pollutants resist settling and biodegradation. Let us have a look on some common tough materials and how the method handles them.

Dyes and Organic Molecules

Dyes often pass through biological stages. Electrocoagulation breaks dye molecules and binds fragments. The process can lower colour and chemical oxygen demand in one pass. Plants that treat textile waste find this step useful.

Heavy Metals and Toxic Ions

Heavy metals attach to metal hydroxide flocs and leave the water with the settled mass. This method can reach lower metal levels than some chemical coagulants. Careful control of pH and current improves metal capture.

Oils and Emulsions

Oil droplets that resist coalescing can join flocs after treatment. Electrocoagulation destabilizes emulsions and lets oils separate. This step eases later polishing and reduces need for extra chemicals.

Design and Operation Considerations

Good design and steady operation make a system work long term. Faults in these areas cause poor performance and high costs. Let us have a look on some design points and operational controls that impact results.

Reactor Layout and Flow Control

Reactors must match plant flow and pollutant load. Smooth flow prevents dead zones and improves contact time. Modular reactors allow step by step scale up and help with maintenance.

Power Use and Controls

Power supply and control units set current density and run cycles. Smart controls can change settings as load varies. Monitoring systems record voltage current and sludge formation to guide tuning.

Sludge Handling and Post Treatment

Sludge volume and chemistry differ from chemical coagulation residues. Proper dewatering and safe disposal matter for compliance. Operators may reuse metal rich sludge in some industrial paths after testing.

Challenges and Maintenance

Plants must plan for wear and for changing inflows. Ignoring these issues harms system life and performance. Let us have a look on some common challenges and how teams fix them.

Electrode Wear and Replacement

Electrodes wear over time and need replacement. Regular inspection and clear replacement plans keep systems online. Using sacrificial plates in a modular frame makes swaps faster.

Scaling and Fouling

Hard water and organic load can form scale on surfaces. Periodic cleaning restores performance. Design for easy access cuts downtime and lowers labour cost.

Regulatory and Safety Notes

Operators must track metal discharge and worker safety. Safety plans for handling electricity and sludge protect staff and public waters. Clear records help with audits and approvals.

Conclusion

Electrocoagulation to Remove Tough Pollutants in STPs shows strong promise as a practical step to improve plant outputs. The method can cut hard to treat chemical dyes, oils and metals with less chemical input and with manageable sludge. Plant teams can test pilot reactors tune power and choose electrodes to match local needs. Operators who adopt this method often see easier compliance and smoother downstream polishing. If you want more details on system design tests or a consultation please get in touch with our team today. We can review your plant and suggest a tailored plan.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com