- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

One of the major reasons behind the development of the Indian economy is industrial growth. The industries work in all states of the country, including the pharmaceuticals and chemicals, the textile industry, food processing, metal finishing and petrochemicals. Although this growth makes the economy stronger, it also results in the production of huge amounts of industrial wastewater in form of effluent. Industrial effluent in contrast to domestic sewage usually comprises complex substances including toxic chemicals, heavy metals, oils, acids, alkalis and large organic loads.

When released unorganized, industrial effluent may cause enormous destruction to the ecosystems, contaminate ground water in addition to being extremely harmful to the well-being of humans. To overcome these problems, industries must install Effluent Treatment Plants to treat wastewater before discomfort or reuse. Netsol Water is a major Effluent Treatment Plant Manufacturer in India that offers advanced, customized, and regulatory compliant ETP solutions that will satisfy various needs of industries in the country.

· Wastewater Generation and Industrial Expansion: The industrial industries of India produce millions of liters of wastewater every day. Effluents generated by each industry have their specific characteristics depending on the raw materials, production procedures and the type of chemicals used. This wastewater needs proper treatment systems so that it is managed in a proper way.

· Sustainability and Environmental Protection: Industrial discharge, when left untreatedis able to contaminate rivers, lakes, and farmland. Effluent Treatment Plants are very effective in the reduction of harmful pollutants like BOD, COD, TSS, oil and grease and heavy metals which ensure the safety of the environment.

· Regulatory Compliance: Strict discharge norms have been set up by the Central Pollution Control Board (CPCB) and respective State Pollution Control Boards. These standards are mandatory to industries to escape fines, legal prosecutions or closure of operations.

· Water Reuse and Water Conservation: The treated effluent may frequently be used in cooling towers, boiler feed system, landscaping, or other industrial applications thereby saving on freshwater use.

· National Exposure and Business Experience: Netsol Water is a well-established brand with a reputation of being a good reliable manufacturer of Effluent Treatment Plants to the industries in India. Having a long history in the field of wastewater engineering, we offer tailored solutions, which will solve difficult problems of industrial effluents.

· Wastewater Analysis and System Design: All ETP projects start with laboratory analysis of the nature of the effluents such as pH levels, BOD, COD, TDS, oil content and existence of heavy metals. According to these parameters, we develop a specific treatment process that guarantees the efficient pollutant elimination and regulation.

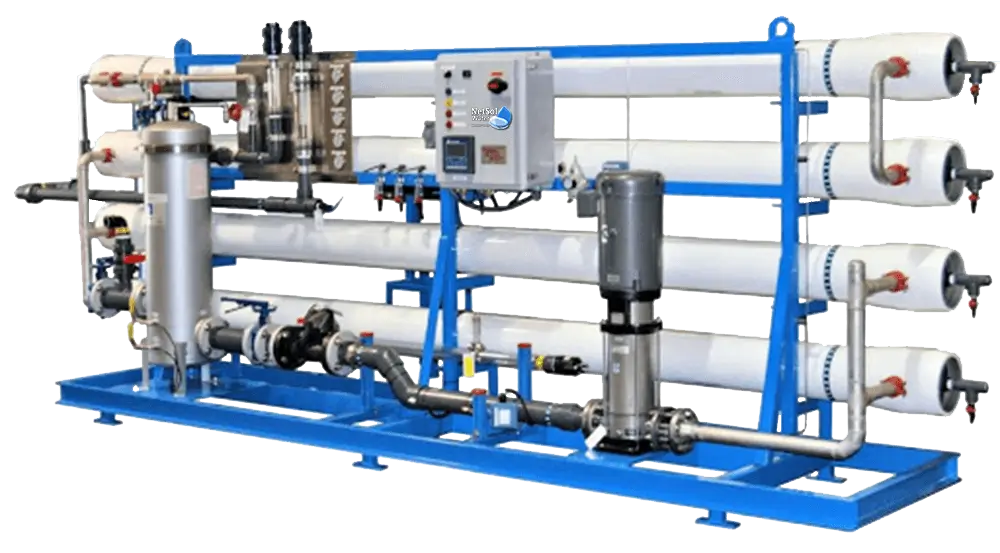

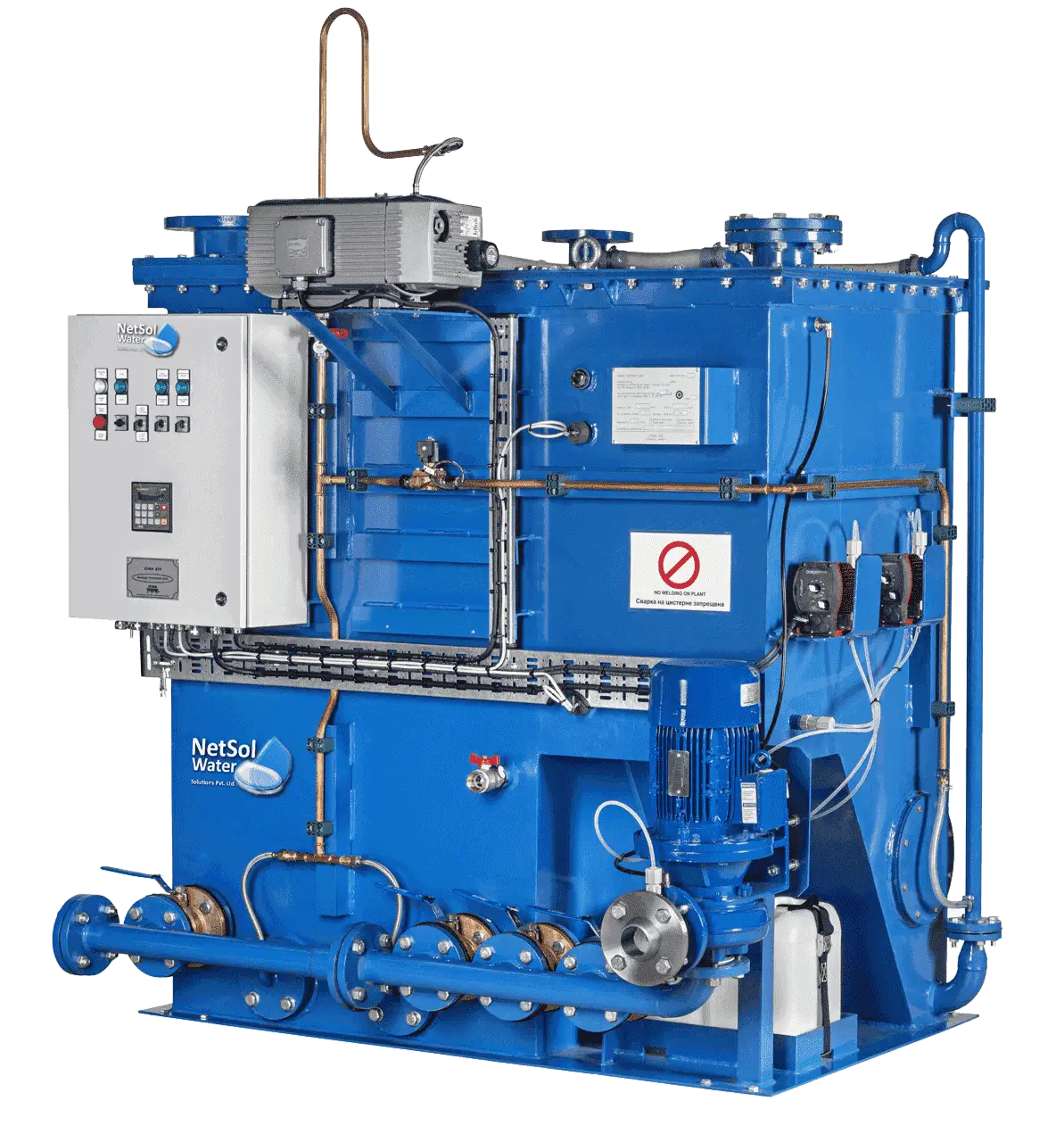

· Manufacturing Standards that are of Good Quality: Durable tanks, corrosion resistant pipes, high performance pumps, chemical dosing systems and automated control panels are used to manufacture our ETP systems. Every plant is designed to operate in hard industrial conditions and make it last long.

· End-to-End Project Execution: Netsol Water offers total project support including conceptual design, fabrication till commissioning and training of the operators. We are also providing maintenance services and technical support to facilitatea smooth running of the plants.

· Small-Scale ETP Systems: In the case of small manufacturing units and processing plants, we sell ETP systems with a minimum of 5 KLD (Kilo Liters per Day). These are small systems that are effective in industries that produce only small waste water. Our 10 KLD and 25 KLD plants are also offered to small- to medium-enterprises.

· Medium-Scale ETP Systems: Moderate industries that emit effluents normally need systems of 50 KLD to 100 KLD. The plants are configured to accommodate stable amounts of wastewater and at the same time be effective in terms of treatment.

· Big and massive Cluster ETP Systems: In the case of large industries and industrial estates, Netsol Water develops the ETP systems at the capacity of 250 KLD, 500 KLD, 1000 KLD (1 MLD) and multi-MLD. These large capacity plants are designed to operate continuously and under heavy load of pollutants.

· Primary Treatment Processes: Primary treatment is aimed at the elimination of large solids, oil and floating materials. It involves screening and oil and grease taps as well as equalization tanks to stabilize the quantity of wastewater.

· Chemical Treatment: Coagulation and flocculation are done by chemical dosing to get rid of suspended solids and dissolved contaminants. Neutralization tanks rectify the pH levels to safe levels.

· Biological Treatment: The polluted organic matter is broken by biological treatment that includes Activated Sludge Process (ASP) or Moving Bed Biofilm Reactor (MBBR).

· Advanced Filtration and Tertiary Treatment: Additional improvement in treated water quality is done by pressure sand filters, activated carbon filters and advanced membrane systems. Safe discharge is guaranteed through disinfection units.

· Sludge Handling Systems: The formation of sludge during treatment is thickened and the process of dewatering is performed by filter presses or centrifuges to dispose of it safely.

· Equalization and Effluent Collection: The first stage in industrial wastewater treatment is equalization in a tank where the flow and the concentration of the pollutants are equalized.

· Primary and Chemical Treatment: Big particles and oil are separated and then fine suspended solids and contaminants are separated through chemical dosing.

· Biological Degradation: Bacteria decompose organic components of aeration tanks and greatly lower the level of both BOD and COD.

· Elucidation and Ostriction: Treated water moves through clarification and filtration units to eliminate any impurities.

· Discharge or Reuse: The resulting treated effluent is discharged and meets the discharge standards or may be utilized in the industrial processes.

· Pharmaceutical Industry: Production of pharmaceuticals produces effluent that is chemically complex and thus needs high level treatment.

· Textile and Dyeing Industry: The units manufacturing textile waste water generate colored waste water which has dyes and chemicals which are not allowed to be discharged without treatment.

· An Industry of Chemicals and Petrochemicals: These industries produce effluent that has high organic and chemical loads that demand multi-stage treatment.

· Food and Beverage Processing: Organic rich wastewater is produced by food processing plants, which requires biological treatment.

· Metal Finishing and Electroplating: Chemical treatment has toeliminate heavy metals in wastewater.

· Capacity and Flow Rate: The overall cost is largely affected by the capacity of ETP. A 10 KLD plant is cheaper than a 500 KLD system or 1 MLD system because of the difference in equipment size and the infrastructure needs.

· Complexity of Effluent Composition: Very polluted effluent that has toundergo several treatment processes is costly to the project.

· Automation and Customization: Investment may be needed in ETPs that are highly automated, monitored and can be integrated with Zero Liquid Discharge (ZLD) systems, but this would pay off long-term.

· Operation and maintenance consideration: The cost of investing in good equipment lowers the expenditures on maintenance and increases work performance in the long term.

Netsol Water combines technical expertise, customized engineering solutions, and high-quality manufacturing to deliver reliable effluent treatment systems across India. Our wide capacity range, advanced technologies, and dedicated after-sales service ensure long-term performance and regulatory compliance. We focus on sustainable wastewater management solutions that support industrial growth while protecting the environment.

Conclusion

Industrial development must go hand in hand with environmental responsibility. Proper treatment of industrial effluent is essential to protect natural resources, maintain regulatory compliance, and ensure sustainable growth. Effluent Treatment Plants play a key role in removing harmful contaminants and enabling safe discharge or reuse of wastewater.

As a trusted Effluent Treatment Plant Manufacturer in India, Netsol Water delivers innovative, scalable, and cost-effective treatment solutions designed for diverse industrial sectors. With strong engineering capabilities and nationwide project execution experience, we help industries operate responsibly while maintaining productivity and compliance.