- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

Bikaner, an important industrial hub in Rajasthan, is facing increasing environmental challenges as its industries continue to expand. Rapid industrialisation has led to an increase in effluent discharge, which, if left untreated, can have severe consequences for the region's water bodies, soil, and overall ecological balance. This is where effluent treatment plants (ETP Plants) play a crucial role. We'll explore the importance of ETP plant and the role of Effluent Treatment Plant manufacturer in Bikaner in addressing the region's wastewater management needs.

Effluents generated from various industrial processes, such as textiles, tanneries, chemicals, and pharmaceuticals, contain a wide range of pollutants, including heavy metals, organic compounds, and toxic substances. If discharged directly into water bodies, these pollutants can have devastating effects on aquatic life, contaminate groundwater reserves, and pose serious health risks to local communities. Ensuring effective effluent treatment is not only a legal requirement but also a moral responsibility for industries operating in Bikaner. The implementation of ETPs is crucial for maintaining environmental sustainability and promoting the region's long-term economic growth.

Bikaner is home to several reputable ETP plant manufacturers that offer customised solutions to meet the unique wastewater treatment requirements of various industries. These manufacturers employ a team of experienced engineers and technicians who design and install ETPs that are not only efficient but also comply with the latest environmental regulations.

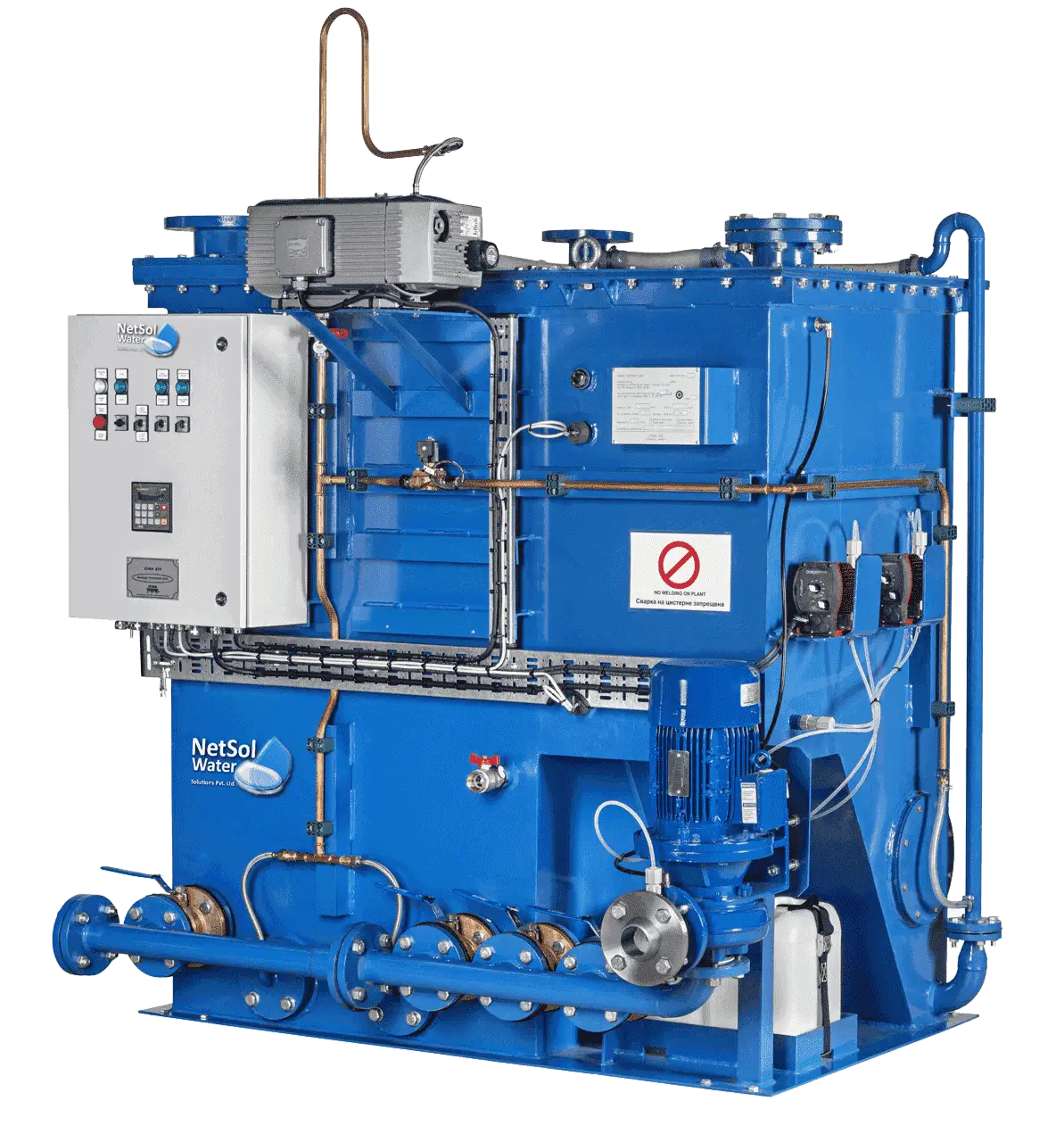

One such manufacturer is Netsol Water, a leading provider of effluent treatment solutions in Bikaner. With years of expertise in the field, Netsol Water offers a comprehensive range of ETP solutions, including:

1. Preliminary Treatment: This stage involves the removal of large solid particles, oil, and grease from the effluent through processes like screening, oil skimmers, and grit chambers.

2. Primary Treatment: In this step, suspended solids and a portion of the dissolved organic matter are removed through sedimentation or flotation processes.

3. Secondary Treatment: Here, biological processes are employed to break down the remaining organic matter in the effluent. This is often achieved through aerobic or anaerobic treatment methods.

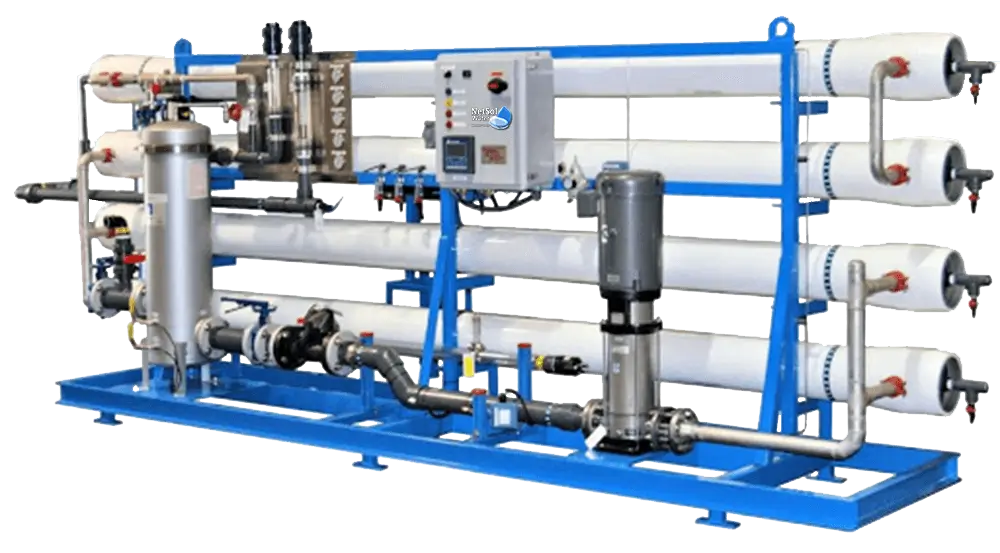

4. Tertiary Treatment: Depending on the specific requirements, this stage may include advanced treatment processes like membrane filtration, activated carbon adsorption, or disinfection to purify the treated effluent further.

Netsol Water takes pride in its state-of-the-art facility, which houses cutting-edge equipment and technology for designing and manufacturing customised ETP solutions. Their team of experts works closely with clients to understand their specific requirements and develop tailored solutions that not only meet regulatory standards but also optimise operational efficiency and cost-effectiveness.

Conclusion

As Bikaner continues to grow industrially, the demand for effective effluent treatment plants will only increase. By partnering with reputable ETP plant manufacturer like Netsol Water, industries in the region can take a proactive step towards environmental stewardship while ensuring their long-term sustainability. Investing in efficient ETPs is not only a wise business decision but also a responsible act towards preserving the region's precious natural resources for future generations.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com