Do Sewage Treatment Plants produce Methane?

In recent years, the majority of efforts to improve the operation of Sewage treatment plants (STPs) have been focused on achieving high effluent quality. However, new problems are currently being considered in order to assure the long-term viability of STPs in terms of both economic viability and environmental effects.

Energy usage and greenhouse gas (GHG) emissions are two criteria that have emerged as a significant determinant of a STP's overall performance. The STPs have been recognized as possible sources of anthropogenic GHG emissions, contributing to climate change and air pollution, according to recent research. Biological wastewater treatment methods release carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O).

Methane emission from Municipal Wastewater Treatment

The anaerobic breakdown of organic material produces methane during the management and treatment of municipal wastewater. The majority of developed nations collect and treat municipal wastewater using centralized aerobic wastewater treatment facilities. These systems emit modest amounts of methane, but they also create huge volumes of biosolids, which can result in high methane emissions rates.

In terms of CH4 emissions from STPs, it was discovered that around 1% of the incoming chemical oxygen demand (COD) to the STPs contained methane. This quantity is greater than the amount of carbon dioxide averted by using the biogas produced in anaerobic digestion. The chief sources of methane found were the primary sludge thickener, the centrifuge, the exhaust gas of the cogeneration plant, the buffer tank for the digested sludge, and the storage tank for the dewatered sludge in the sludge line units where anaerobic digestion is carried out. These units account for around 72% of the STP's methane emissions, with the remainder emissions coming from the biological reactors.

Minimization of methane production_

CH4 emissions can be reduced by covering thickening sludge tanks and sludge disposal tanks to prevent gas leaks and capturing emissions with hoods that can be burned with surplus biogas. Methane enters the plant from the outside via the influent, which comprises CH4 created in the sewage, in addition to the methane produced in the plant.

Methane (CH4)Removal

Biological methods based on biofilter systems to remove CH4 from waste gaseous emissions have been explored since the early 1990s, but they have yet to be consolidated at an industrial scale. Several biological processes can convert methane to CO2 (1 mol to 1 mol), allowing for a reduction in total GHG emissions in CO2 equivalents since CO2 has a lower warming factor than methane.

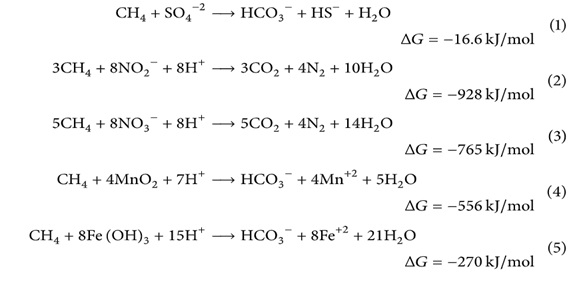

In the presence of oxygen, methanotrophic bacteria oxidize CH4 in aerobic circumstances. Another alternative is to use anaerobic circumstances and take use of bacteria and archaea's ability to oxidize CH4 utilizing sulphate, nitrite, nitrate, Mn+4, or Fe+3 as electron acceptors:

Because of the poor solubility of CH4, biofilters must be operated at long residence times (2–30 minutes). As a result, the focus has shifted to removing CH4 directly from the liquid phase before it is released into the atmosphere. The anaerobic methane oxidation is combined with a denitrification process that utilizes the methane as an electron donor to achieve this elimination. Methane, as well as nitrite and nitrate, are eliminated from the effluent in this example. Furthermore, not only are GHGs eliminated, but the electron donor needs for denitrification processes are reduced, lowering the costs of prospective carbon source addition.

The methane that remains in the exhausted gaseous stream after the biological activities, can be subjected to a post-combustion process.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated Wastewater problems by strategically integrating modern treatment technology with practical solutions.

Think of us when it comes to wastewater management for your organisation, adapted to your specific needs! Weprovide a cost-effective method to reuse and recycle water. Deal with us for wastewater treatment equipment’s and develop your business while complying with environmental standards.